Inflation valve for multi-layer tire

A multi-layer tire and valve technology, which is applied to tire inflation valve, tire parts, transportation and packaging, etc., can solve the problems such as the inability to discharge gas and the inability to use the wheel hub, so as to improve efficiency, expand the scope of adjusting tire pressure, The effect of increasing flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

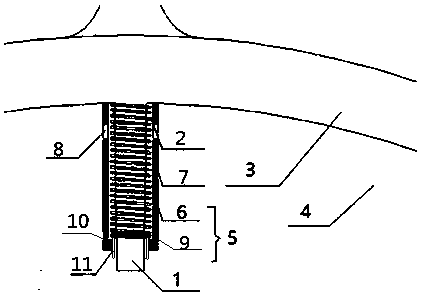

[0023] Such as figure 1 As shown, the present embodiment provides an inflation valve for a multi-layer tire, including a valve for inflating and deflated one of the layers of the tire, the outside of the valve is provided with an external air passage; the external air passage It communicates with the other layer of the tire; the outer air passage is provided with an isolation device to isolate the gas in the other layer from communicating with the outside world, and the gas in the other layer can be released by opening the isolation device.

[0024] Among them, the valve 1 generally includes a valve body and a valve core; the valve core is located inside the valve body, and is mainly used to realize the air intake of the tire and prevent the tire from leaking; the outer wall of the valve 1 is provided with threads, which can be used to connect The inflatable device can also be used to install the valve cap. The valve 1 can also directly adopt the existing American valve or Fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com