Surface nanocrystallization method capable of accelerating vacuum carburizing rate

A vacuum carburizing and nanotechnology, which is applied in the direction of coating, metal material coating process, solid diffusion coating, etc., can solve the problems of long carburizing cycle, uneven carburizing layer structure, high energy consumption, etc., and achieve carburizing The effect of rate increase, accelerated carburizing rate, and uniform carburizing layer structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

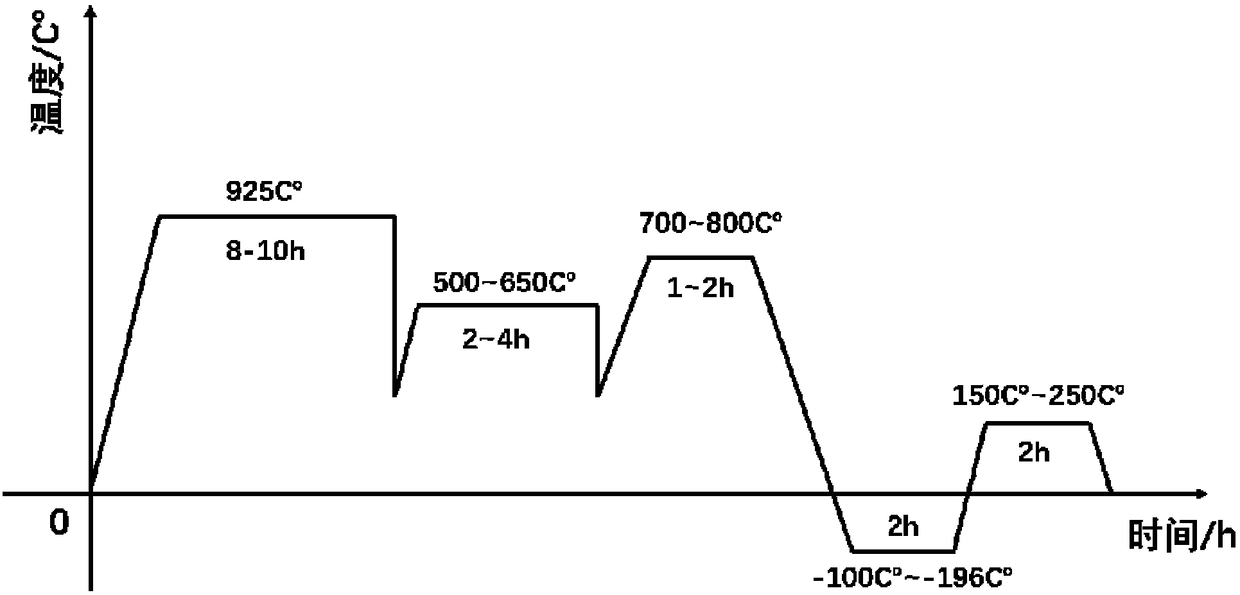

[0019] Specific Embodiment 1: In this embodiment, the surface nanometerization method for accelerating the vacuum carburizing rate is implemented according to the following steps:

[0020] 1. Cut the matrix material into shape, clean the surface of the matrix material with acetone, then polish the surface of the matrix material with sandpaper and polish it, then perform ultrasonic cleaning with absolute ethanol, and obtain the cleaned matrix material after drying;

[0021] 2. Clamp the cleaned matrix material into the fixture to obtain the fixture with the matrix material clamped therein;

[0022] 3. Place the clamp with the matrix material in the supersonic particle bombardment device for surface nano-treatment, move the spray gun during the surface nano-treatment process to obtain uniform surface nano-treatment at different positions on the surface of the substrate per unit time, Obtain a matrix material modified by surface nanometerization;

[0023] 4. Put the surface nano...

specific Embodiment approach 2

[0026] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the base material in step 1 is 18Cr2Ni4WA, 20Cr2Ni4, 12Cr2Ni4 or 20CrMoMn.

specific Embodiment approach 3

[0027] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that in step one, use 60#, 240#, 600#, 800#, 1000#, 2000#, 3000# sandpaper to polish the surface of the base material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com