Heating coil for preparing zone-melting and large-diameter monocrystal

A heating coil, large-diameter technology, applied in induction heating, coil device, single crystal growth, etc., can solve the problems of single crystal growth failure, polysilicon thorns, and belts in the melting zone, etc., to improve melting conditions and save raw materials. , Improve the effect of coil life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings, but the scope of protection of the present invention is not limited to the following specific embodiments.

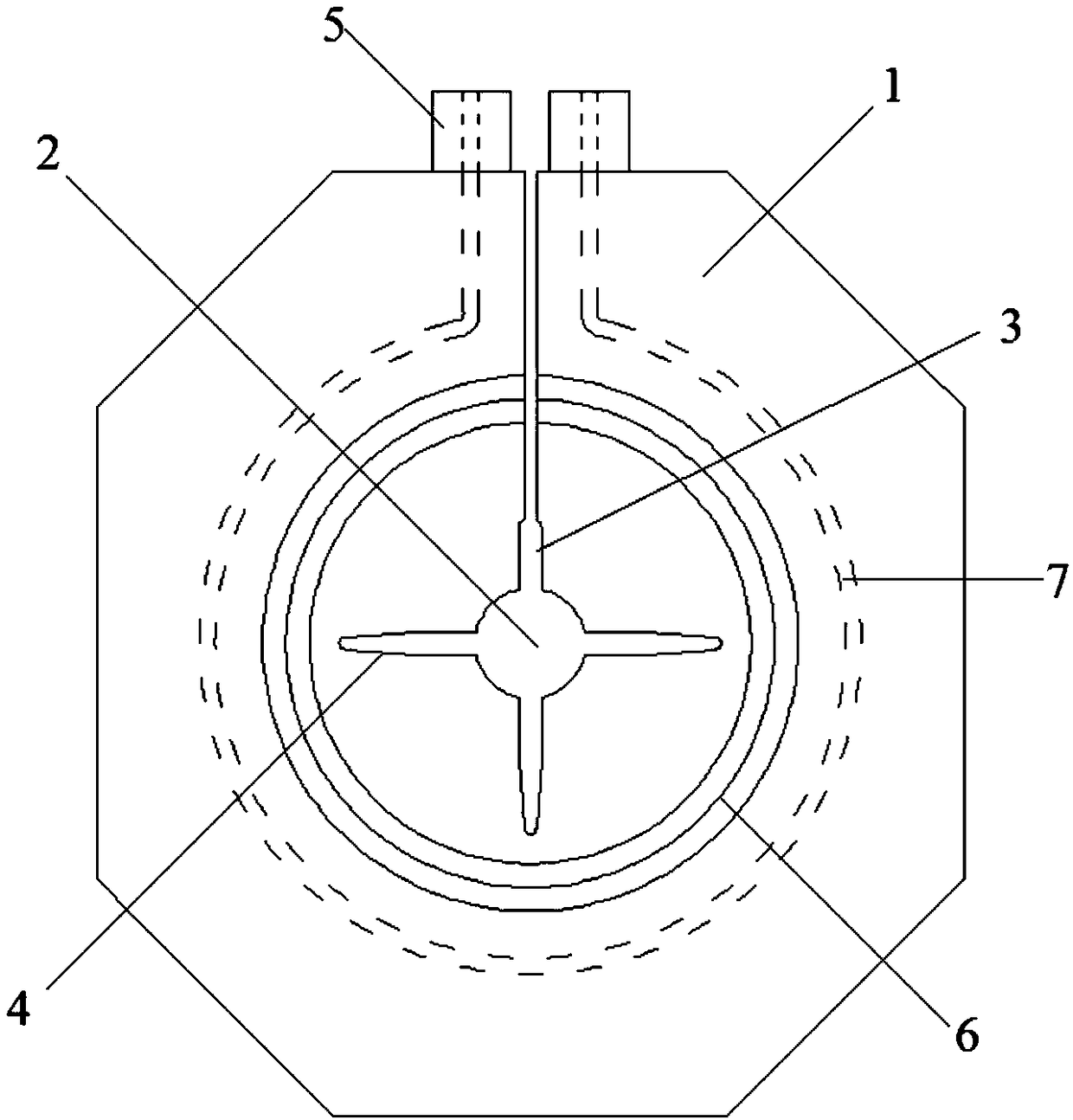

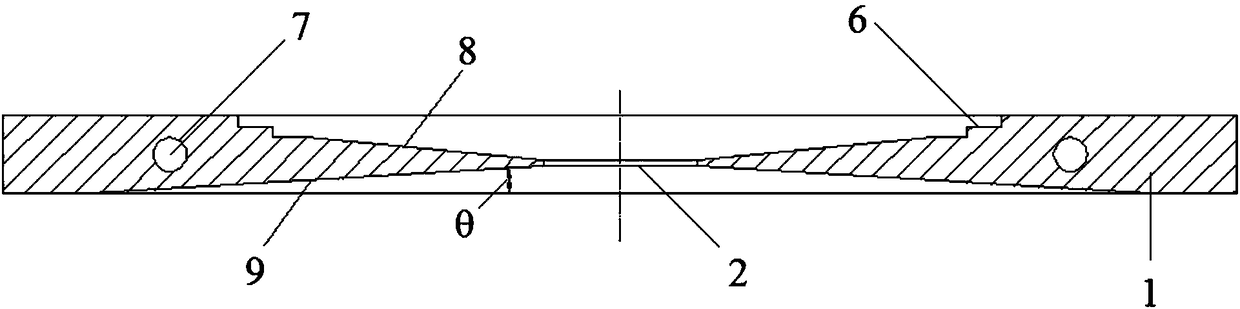

[0015] The heating coil of the invention is used for preparing zone-melted large-diameter single crystals. Such as figure 1 and figure 2 As shown, the center of the coil 1 is an annular needle eye 2 penetrating the upper and lower surfaces of the coil, and four diversion slits penetrating the upper and lower surfaces of the coil are separated on the outer circumference of the needle eye 2 at intervals of 90°. These diversion slots are distributed in a cross, including a main diversion slot 3 and three side diversion slots 4 . Wherein the main flow slot 3 extends to the outside of the coil, and is connected with the flange 5 connecting the electrodes. The three side diversion slits 4 are designed as superimposed V-shaped structures t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com