Solenoid-actuated non-pyrotechnic separation device based on volute spiral spring transmission assembly

A scroll spring and separation device technology, applied in the direction of self-propelled bombs, projectiles, offensive equipment, etc., can solve the problems of large load limit, undetectable and undetectable, and poor environmental adaptability in separation conditions, so as to increase the upper limit of load, Strong bearing capacity and low separation impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

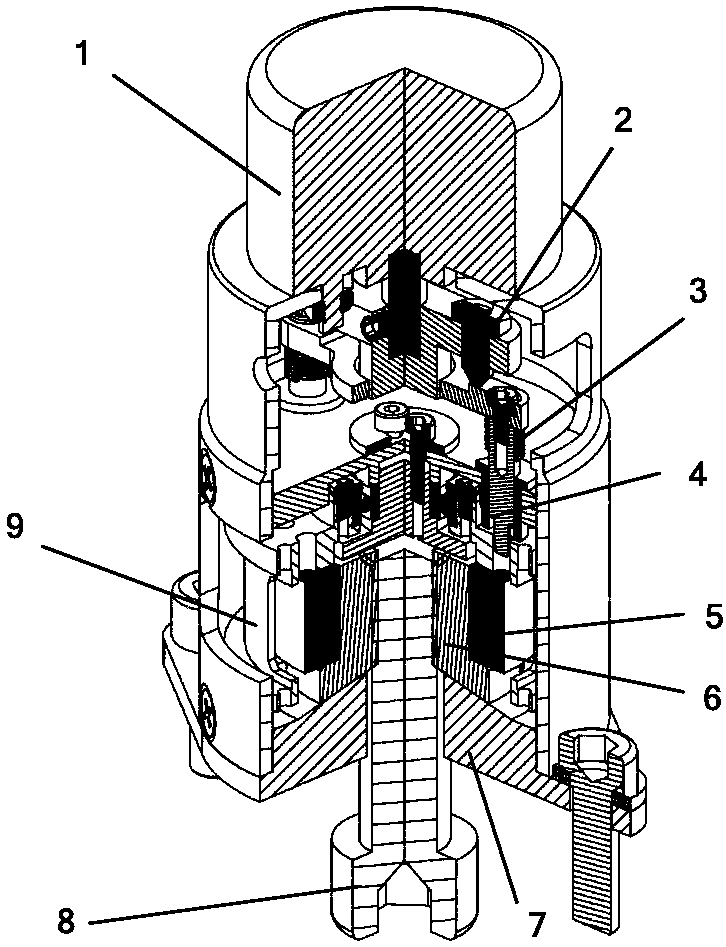

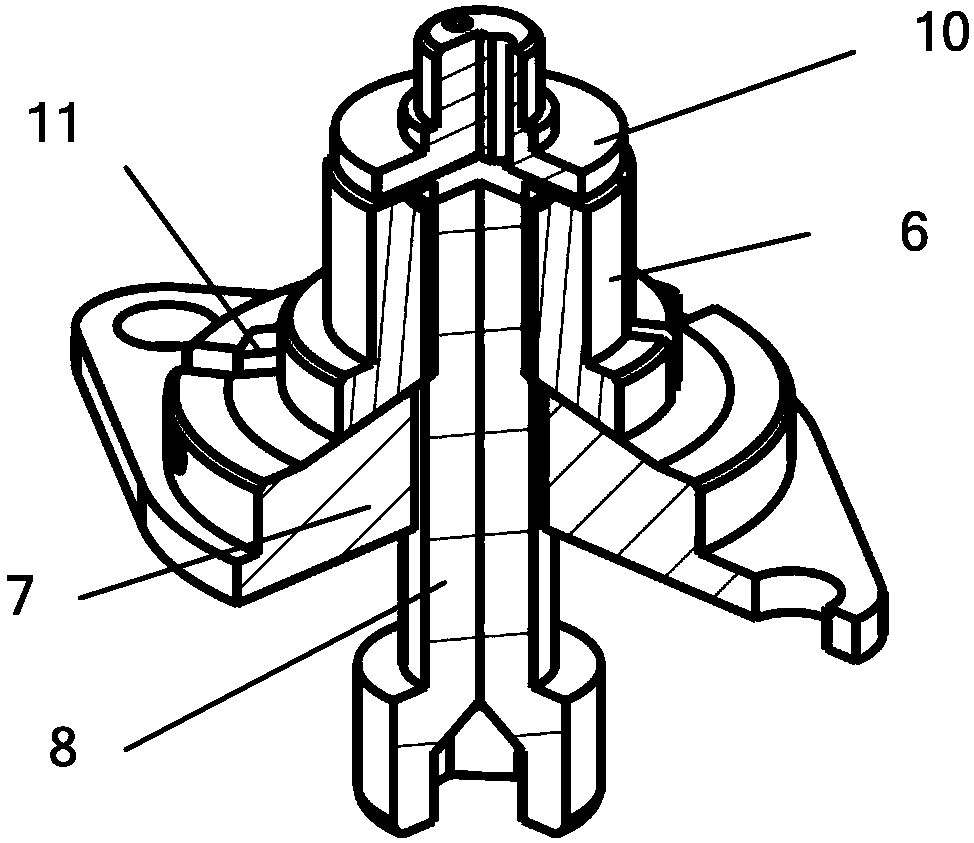

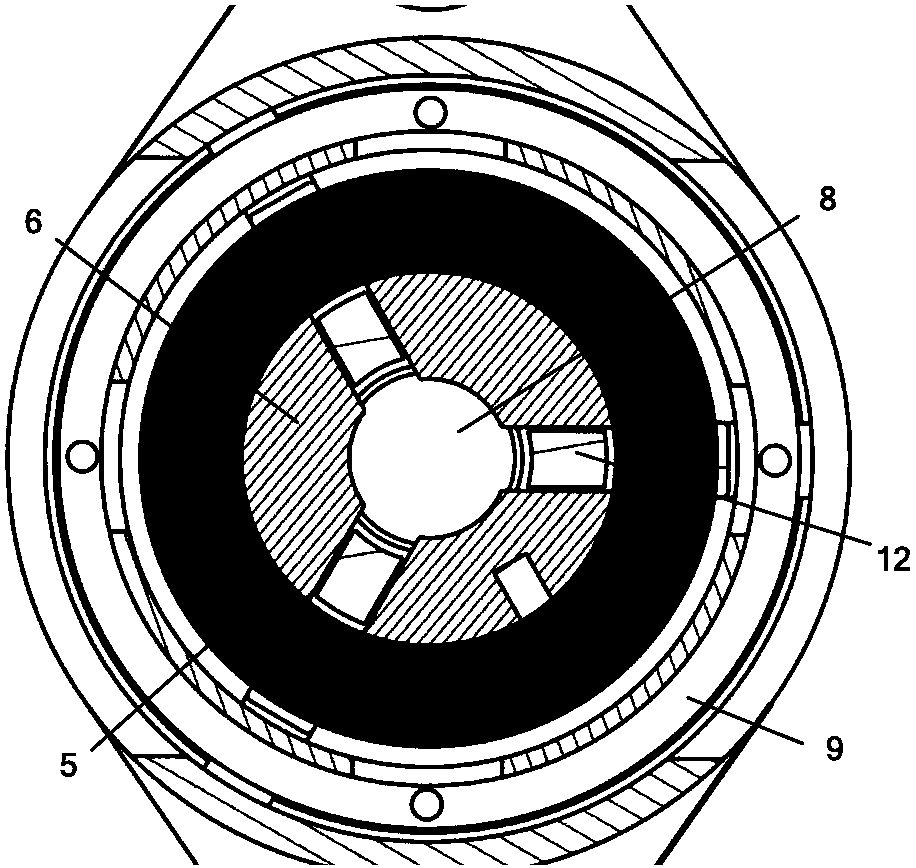

[0020] like Figure 1-4 As shown, an electromagnetically driven non-fire separation device based on a scroll spring transmission assembly, the separation device includes three parts: a split nut part, a scroll spring slow release structure, and an electromagnet release structure part, characterized in that: The split nut part includes an upper block 10, a split nut 6, a nut compression spring 12, a lower block 11, a bottom plate 7, and a bolt 8; the scroll spring slow-release structure includes a scroll spring 5 and a rotating disc 9; the electromagnet releases The structural part includes a rotating electromagnet 1 , a blocking column 2 , a release compression spring 3 , and a release pin 4 .

[0021] The split nut is in contact with the bottom plate 7, the lower end is restricted by the lower block 11, and the upper end is restricted by the upper block 10, so that the split nut 6 can only move in the radial direction, and a nut is installed between the split nuts 6. The com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com