Method and device, device, and storage medium for adjusting the position of a crane for a crane

An adjustment method and the technology of the crane, which is applied to the control of the lifting device, the lifting frame, and the use of feedback, and can solve the problems of low accuracy and long time-consuming preparations for the crane

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

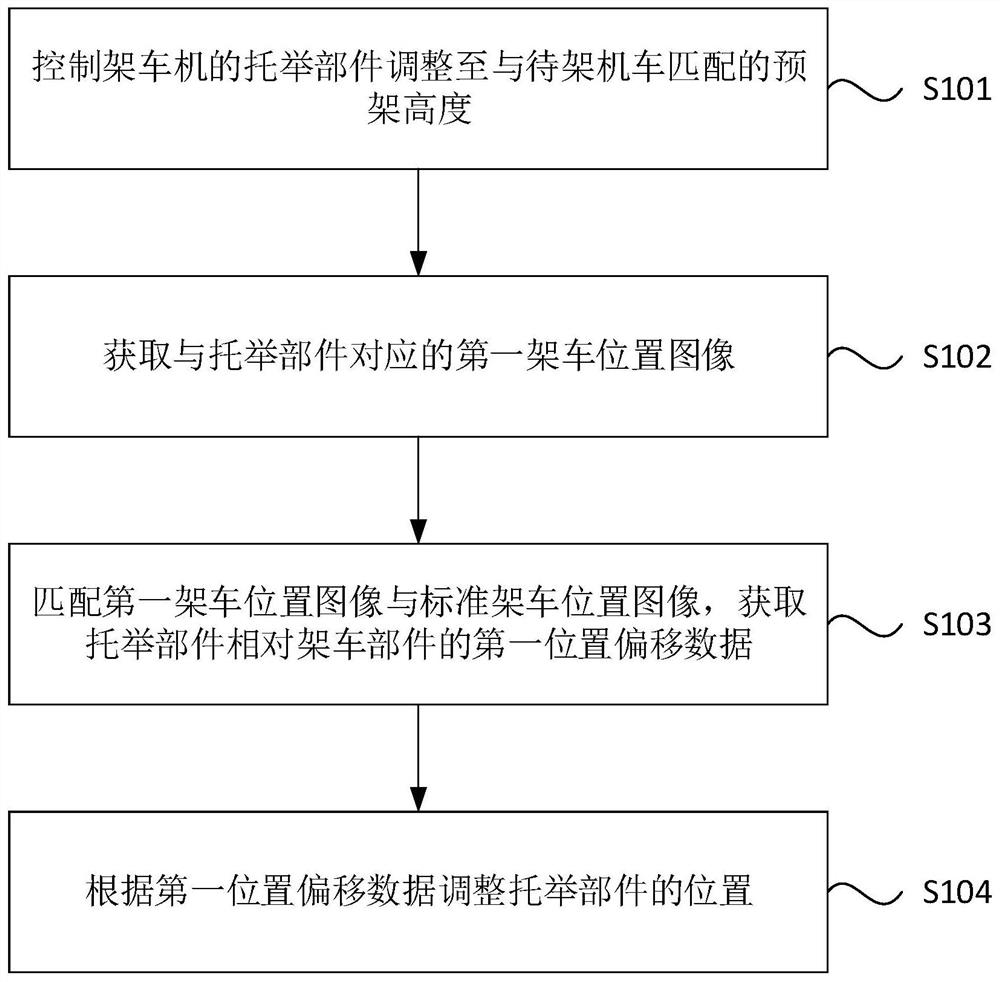

[0050] figure 1 It is a flow chart of a method for adjusting the position of a trolley crane provided by Embodiment 1 of the present invention. The method of this embodiment can be performed by a device for adjusting the position of a trolley crane, which can be implemented through hardware and / or It is realized by software, and generally can be integrated in the control system of locomotive assembly or maintenance. The method of this embodiment specifically includes:

[0051] S101. Controlling the lifting part of the erecting machine to adjust to a pre-erecting position matching the locomotive to be erected.

[0052] What needs to be explained here is that the method for adjusting the position of the hoisting machine in this embodiment is performed after the locomotive to be erected has been parked correctly and the hoisting machine has moved to the hoisting position that matches the locomotive to be erected The method for adjusting the position of the crane of the crane is...

Embodiment 2

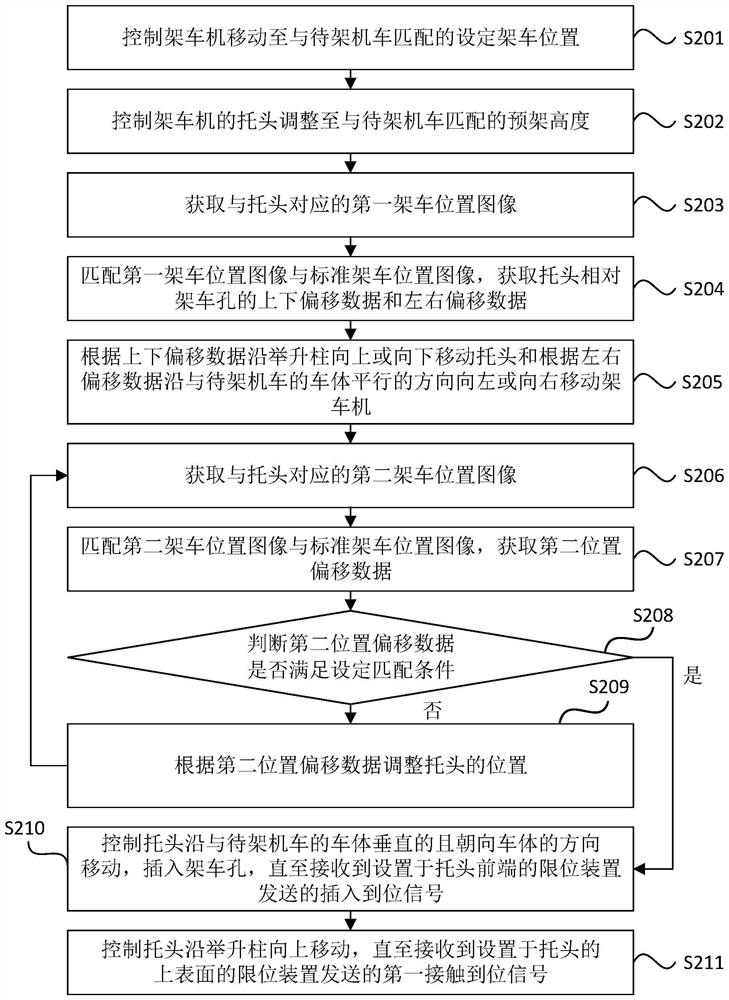

[0073] figure 2 It is a flow chart of a method for adjusting the position of a trolley crane provided by Embodiment 2 of the present invention. This embodiment is optimized on the basis of the above-mentioned embodiments. In this embodiment, the position image of the first trolley is matched with the position image of the standard trolley, and the first position offset data of the lifting component relative to the trolley component is obtained, and the optimized To: match the position image of the first truck with the position image of the standard truck, and obtain the up and down offset data and / or left and right offset data of the lifting component relative to the truck component, wherein the up and down offset data is the lifting component along the frame The data of the movement of the lifting column of the locomotive, and the left and right offset data are the data of the movement of the locomotive in a direction parallel to the body of the locomotive to be erected.

...

Embodiment 3

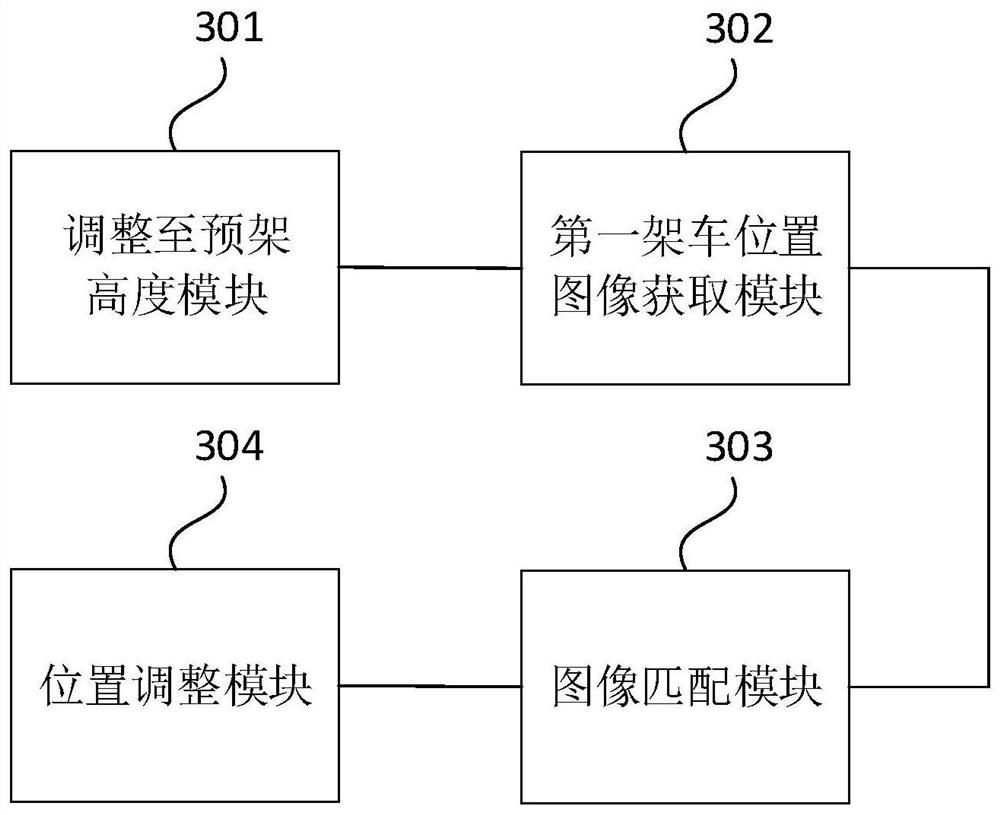

[0116] image 3 It is a structural diagram of a trolley position adjustment device for a trolley crane provided in Embodiment 3 of the present invention. like image 3 As shown, the device includes: an adjustment to pre-frame position module 301, a first vehicle position image acquisition module 302, an image matching module 303, and a position adjustment module 304, wherein:

[0117] Adjust to the pre-set position module 301, which is used to control the lifting parts of the lifting machine to adjust to the pre-set position matching the locomotive to be set;

[0118] The first trolley position image acquisition module 302 is used to acquire the first trolley position image corresponding to the lifting component, wherein the first trolley position image is from the lifting component, along the vertical direction of the vehicle body of the locomotive to be mounted and obtained towards the direction of the car body, including the image of the frame parts of the locomotive to b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com