Motor stator pouring and sealing method and motor stator pouring and sealing tooling

A motor stator and stator technology, applied in the direction of electromechanical devices, manufacturing motor generators, electrical components, etc., can solve the problems of poor sealing, poor effect, affecting the quality of potting, etc., and achieve the effect of reducing poor potting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings.

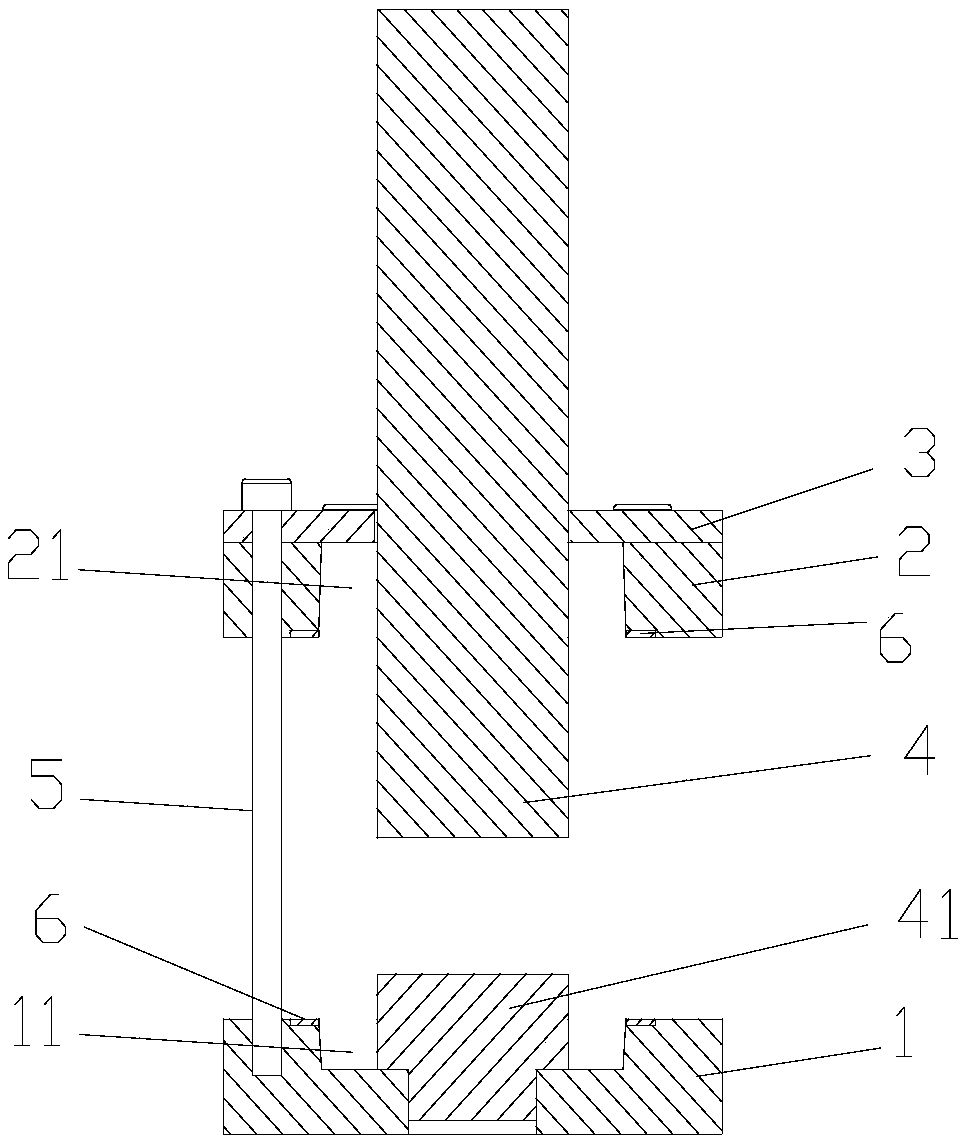

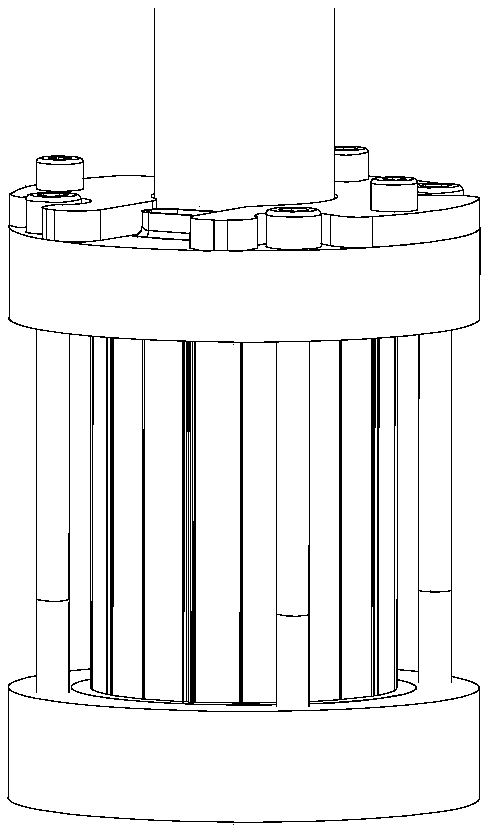

[0018] refer to figure 1 , figure 2 , a motor stator potting tool, including a lower base 1, an upper base 2 on the upper part of the lower base 1, a pressure plate 3, and a mandrel 4. The lower base 1 is provided with a lower base that matches the outer wall of the plastic end cup at the lower end of the stator assembly. Cavity 11, an upper cavity 21 matching the outer wall of the plastic end cup at the upper end of the stator assembly is provided at the axis of the upper base 2, and the inner wall of the lower cavity 11 is an inverted cone that matches the outer wall of the plastic end cup at the lower end of the stator assembly. The inner wall of the lower cavity 12 is tapered to coincide with the outer wall of the plastic end cup at the upper end of the stator assembly. The tapered structure facilitates the smooth detachment of the stator assembly after glue fill...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com