Squeezing, cleaning and dewatering mop bucket for flat-plate mop

A flat mop and mop bucket technology, applied in the field of mop buckets, can solve the problems of reducing the service life of wooden floors, poor operability, and insufficient dryness, and achieve the effects of improving cleanliness, improving cleaning effect, and reducing the number of water changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

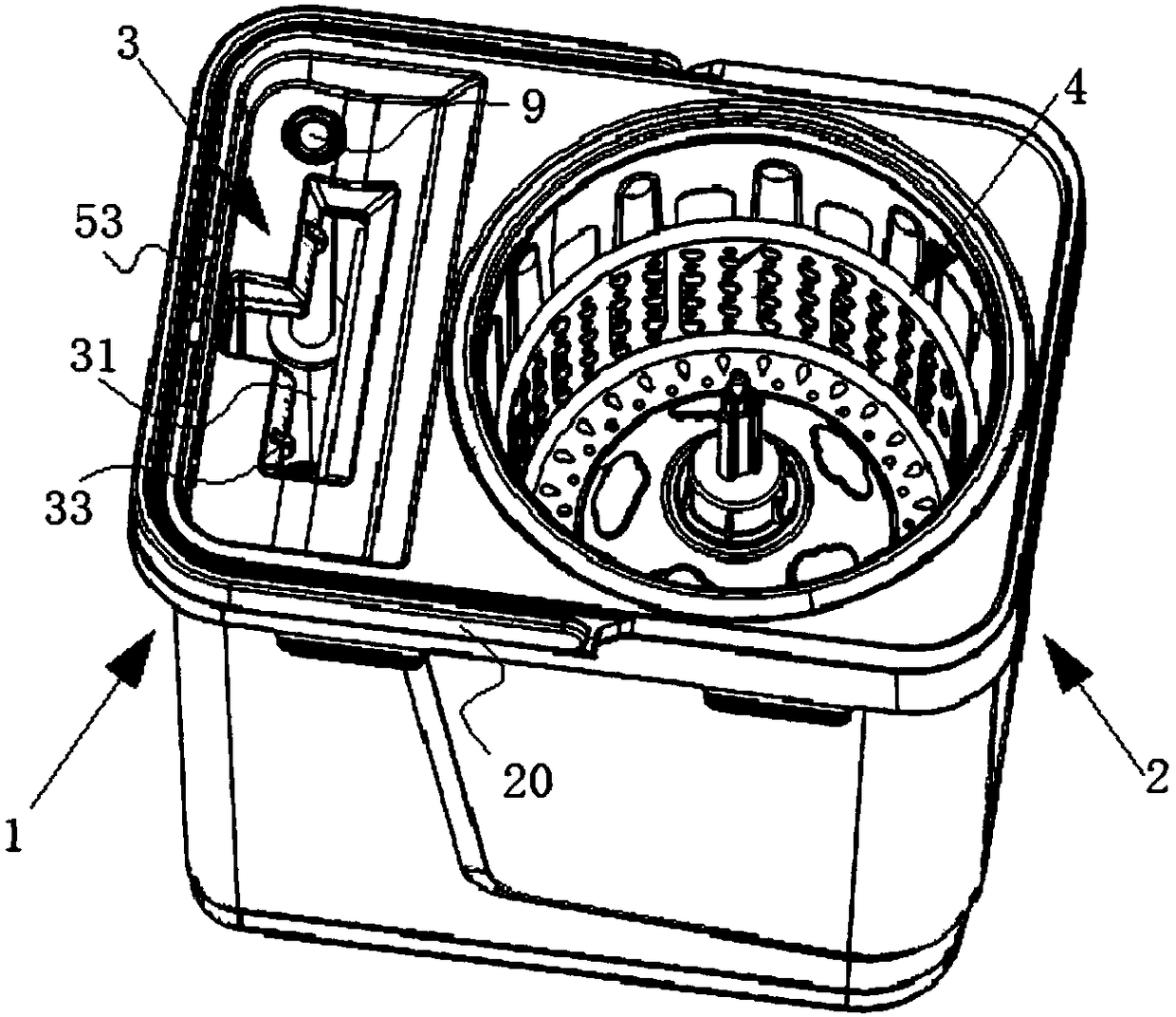

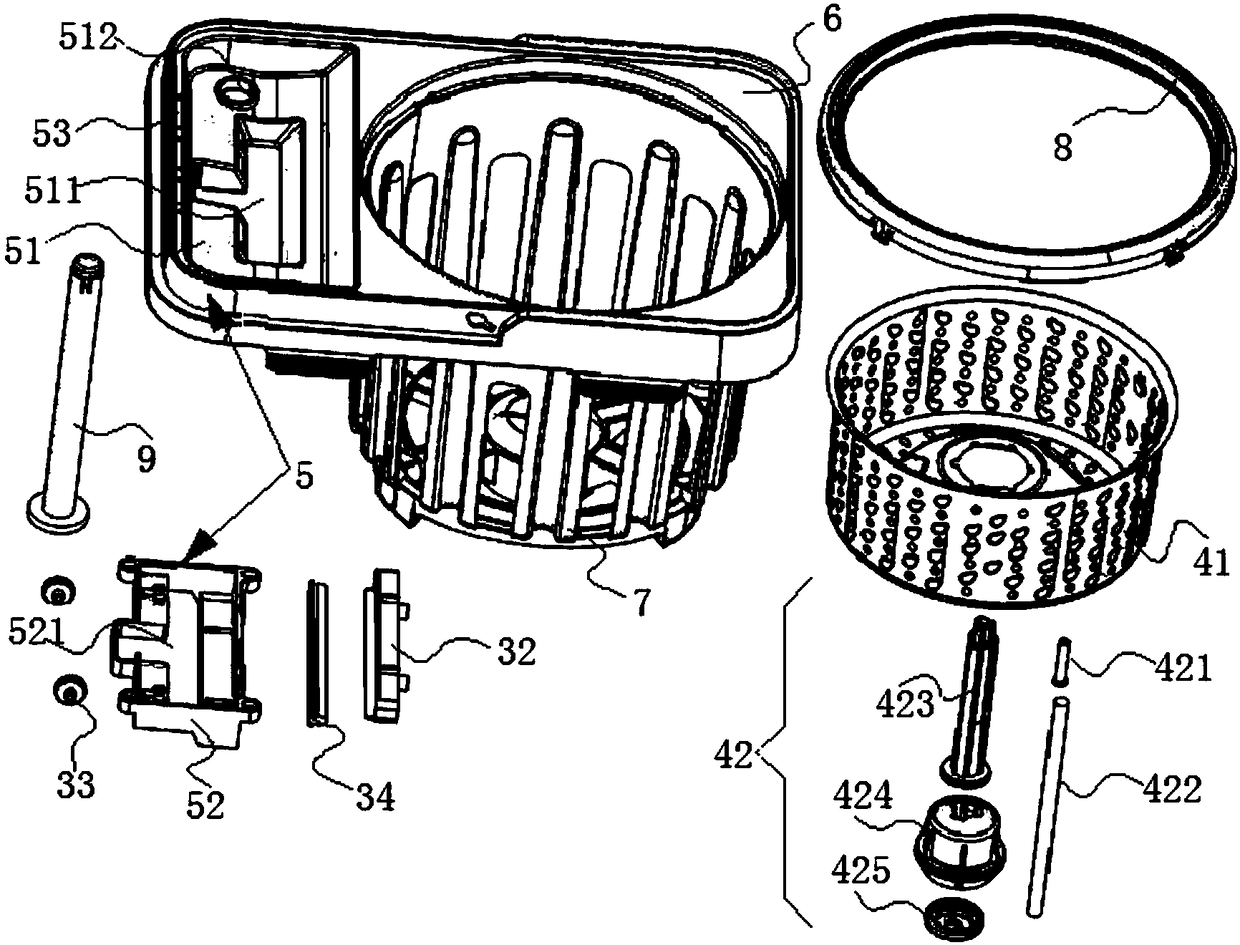

[0042] Embodiment: a kind of dance is used for the mop bucket of extruding, cleaning and dehydration of flat mop, as Figure 1 to Figure 7 As shown, it includes extrusion cleaning area 1 and dehydration area 2. The extrusion cleaning area and the dehydration area are respectively located in two different positions. The extrusion cleaning area is equipped with a mop head capable of Squeeze and slide relative to each other so as to form a rubbing extrusion mechanism 3 that squeezes the wipes on the mop head. Spin-drying mechanism 4 for dehydrating objects.

[0043] In this embodiment, the extrusion cleaning area communicates with the dehydration area.

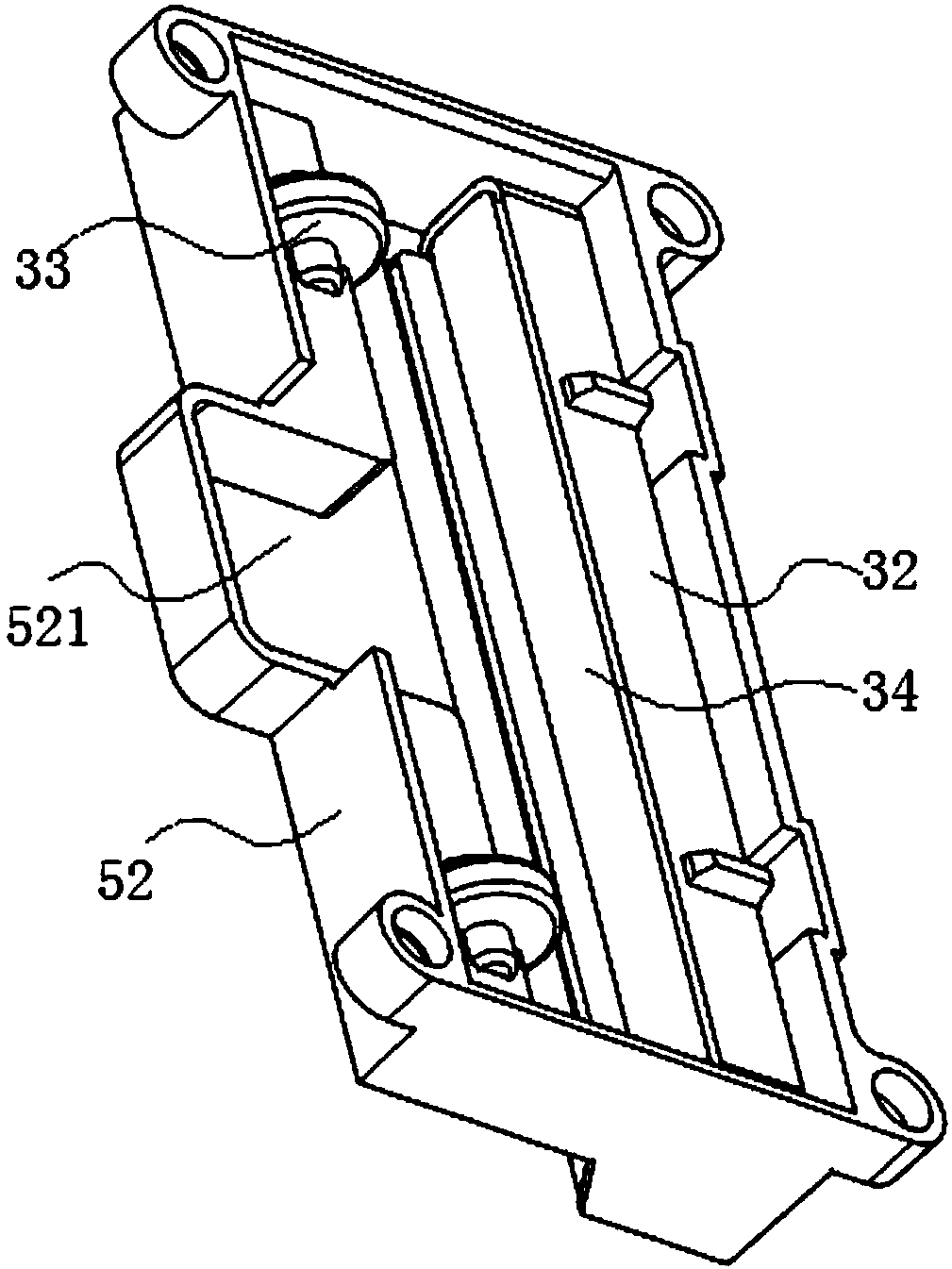

[0044] The mouth squeeze extrusion mechanism 3 includes an extrusion opening 31 for the flat mop to pass through, and the extrusion opening is equipped with an extruder 32 for extruding the wipes on the mop head of the flat mop.

[0045] The extruder 32 is an extruded strip, an extruded sheet or a rotatable squeeze roller, but ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com