Vertical reciprocating electrostatic sprayer

An electrostatic spraying, vertical technology, applied in the direction of electrostatic spraying device, spraying device, etc., can solve the problems of easily damaged parts, difficult replacement, high friction, etc., to achieve the effect of reducing weight, good safety and increasing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

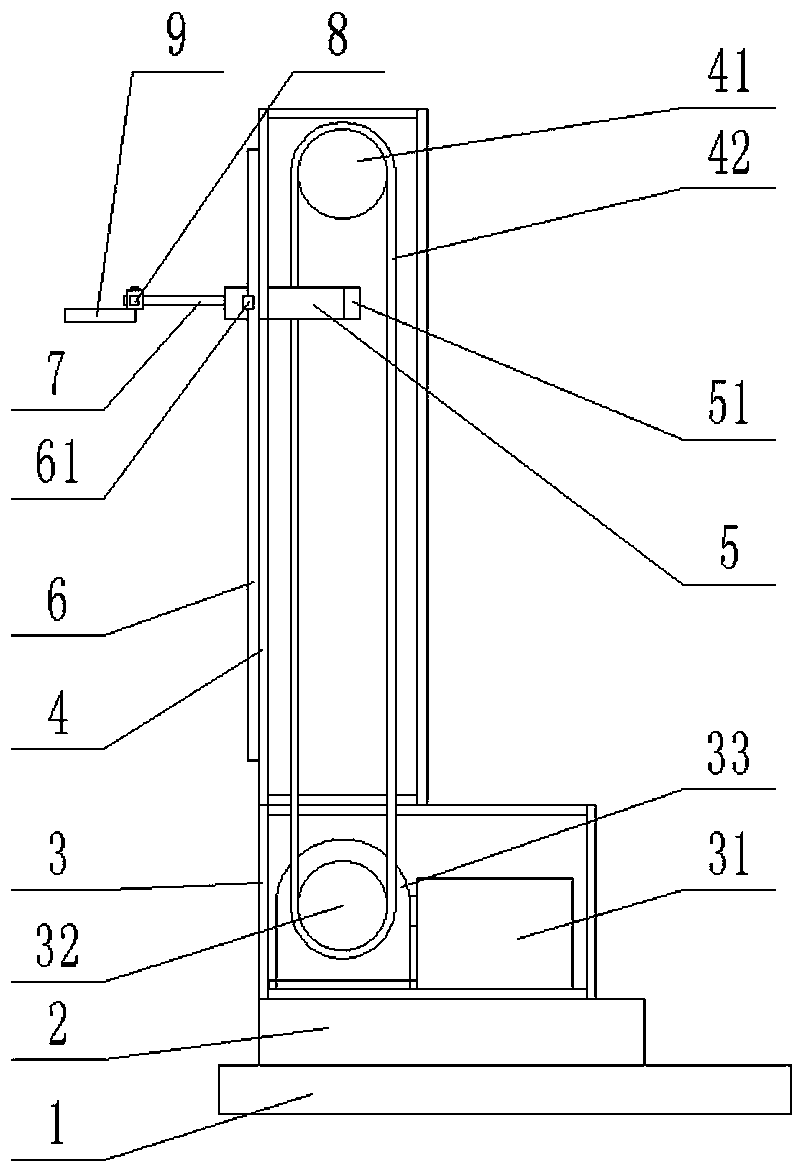

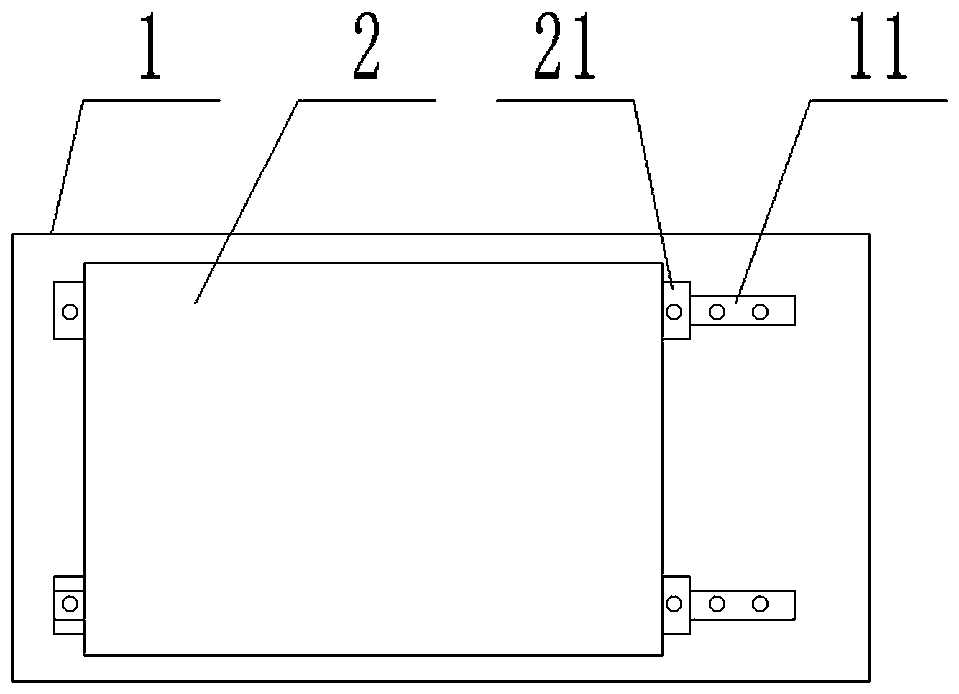

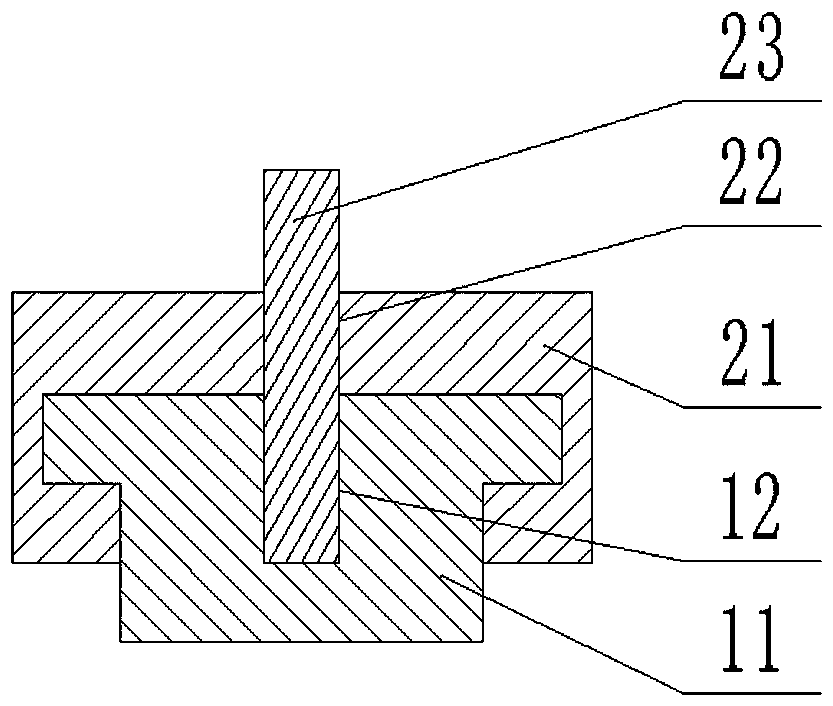

[0018] see Figure 1-4 , a vertical reciprocating electrostatic spraying machine, including a fixed base 1, a mobile base 2, a vertical support 4 and an electrostatic spray gun 9, the fixed base 1 is provided with two slide rails 11, and the slide rails 11 are slidably connected with a slider 21 , the slider 21 is fixedly connected to the bottom of the mobile base 2, and at the same time, a plurality of first through holes 12 are evenly opened on the slide rail 11, and a second through hole 22 is opened on the slider 21. The first through hole 12 and the second through hole 22 is inserted with an adjustment column 23, the position of the mobile base 2 can be adjusted through the slide rail 11 and the slide block 21, and the mobile base 2 can be fixed and prevented from moving through the first through hole 12, the second through hole 22 and the adj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com