Full-automatic test tube dry ice cleaning machine

A dry ice cleaning, fully automatic technology, applied in the direction of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of difficult cleaning of attachments, hidden dangers of operator safety, fragile and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

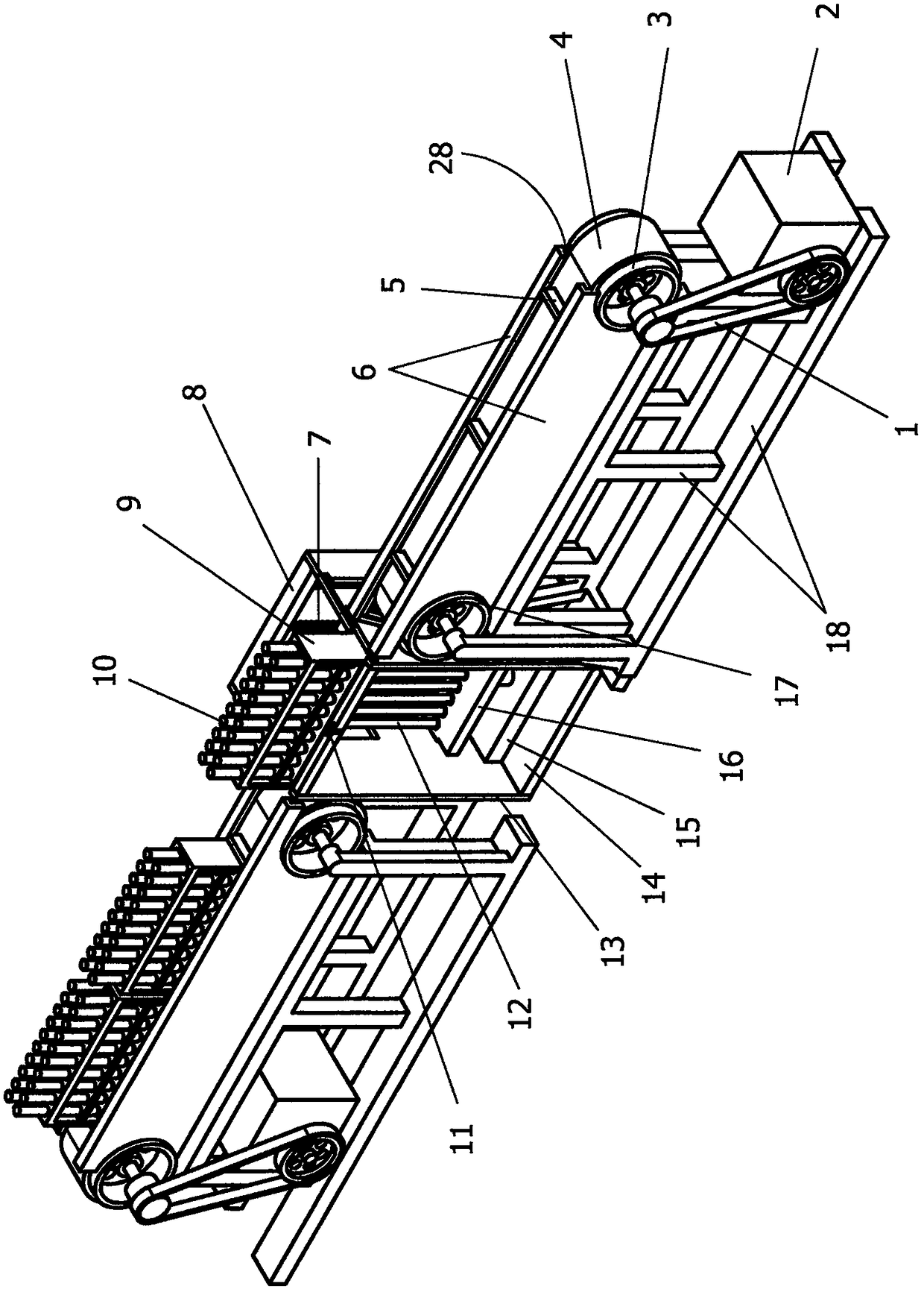

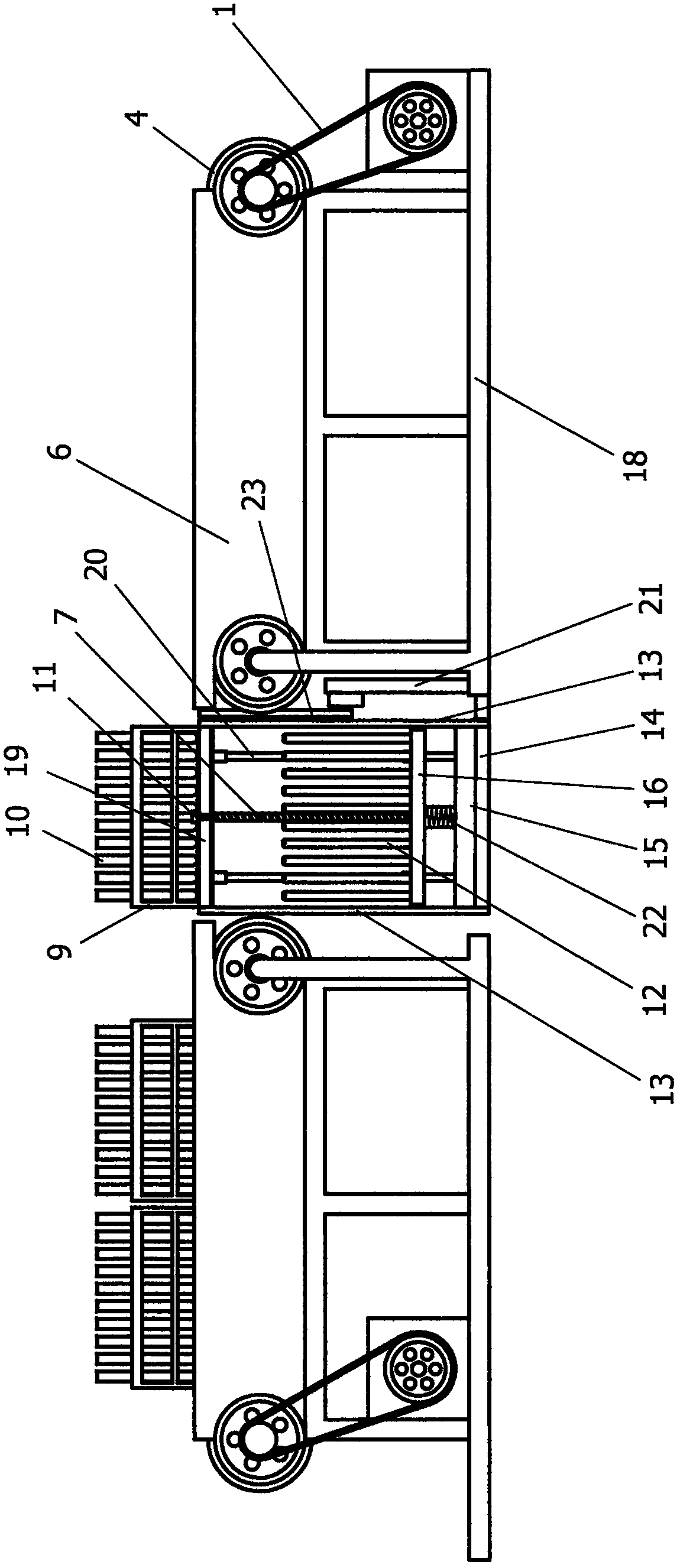

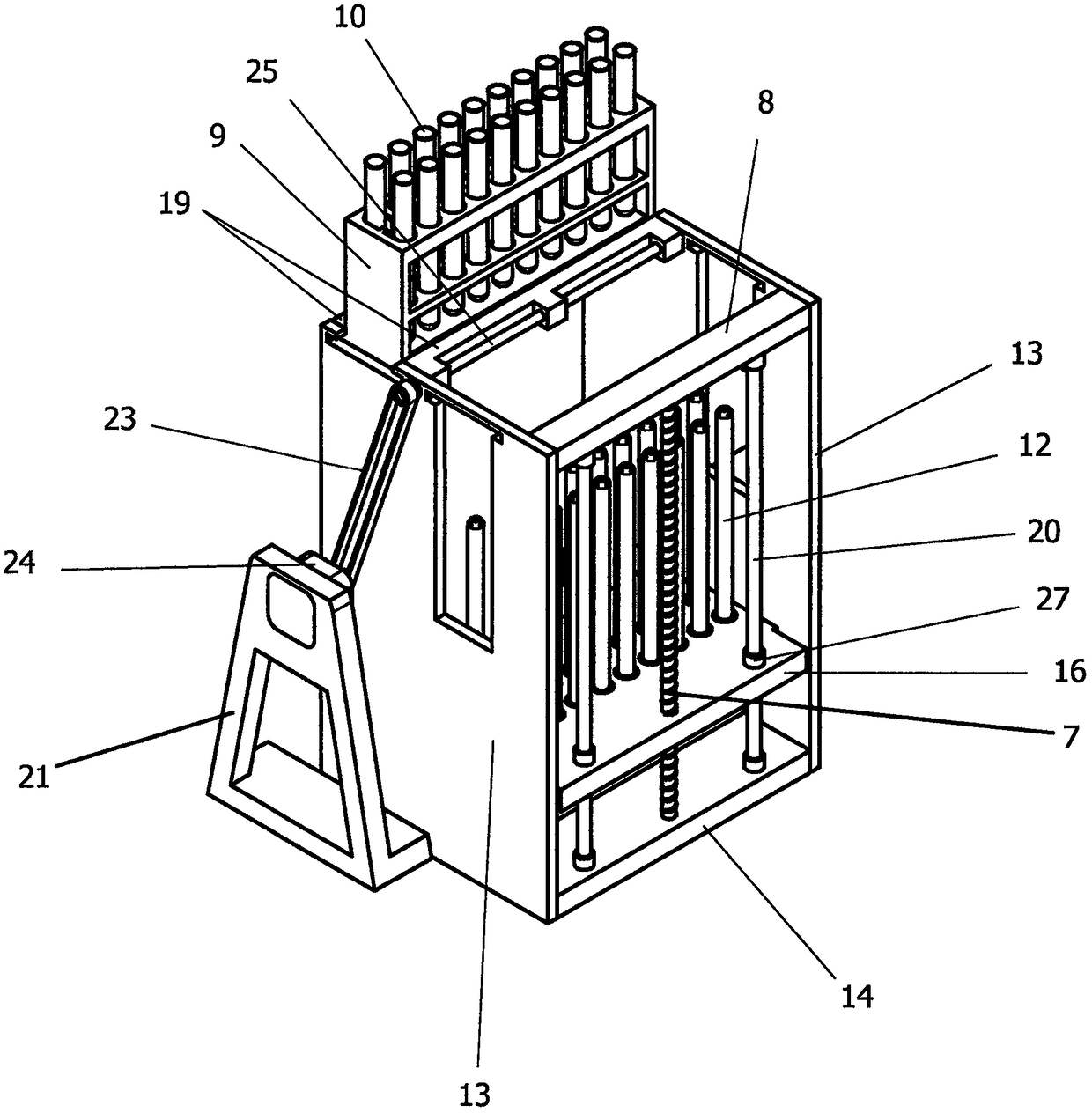

[0016] Such as figure 1 , 2 , 3 shows: the automatic test tube dry ice blasting machine of the present invention includes a dry ice blasting part located in the middle and symmetrically arranged conveying parts located on both sides of the dry ice blasting part.

[0017] The conveying parts on the left and right are identical in structure. Including the conveying frame 18, the driving roller 3 and the driven roller 17 are respectively installed on the two ends of the upper part of the conveying frame 18 through shafts and bearings. In the conveying motor 2 on the conveying frame 18, there is a conveying transmission pair 1 between the output shaft of the conveying motor 2 and the shaft end of the drive roller 3, and the conveying transmission pair 1 can be a chain mechanism or a belt mechanism.

[0018] A belt 4 is wound around the driving roller 3 and the driven roller 17, and baffles 5 are arranged at intervals on the belt 4, and the baffles 5 prevent the conveyed items on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com