Automatic slot broaching machine for lock container and slot broaching process of automatic slot broaching machine

A technology of grooving and locking, which is used in broaching machines, broaching machines, manufacturing tools, etc., can solve problems such as insecurity and affecting processing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

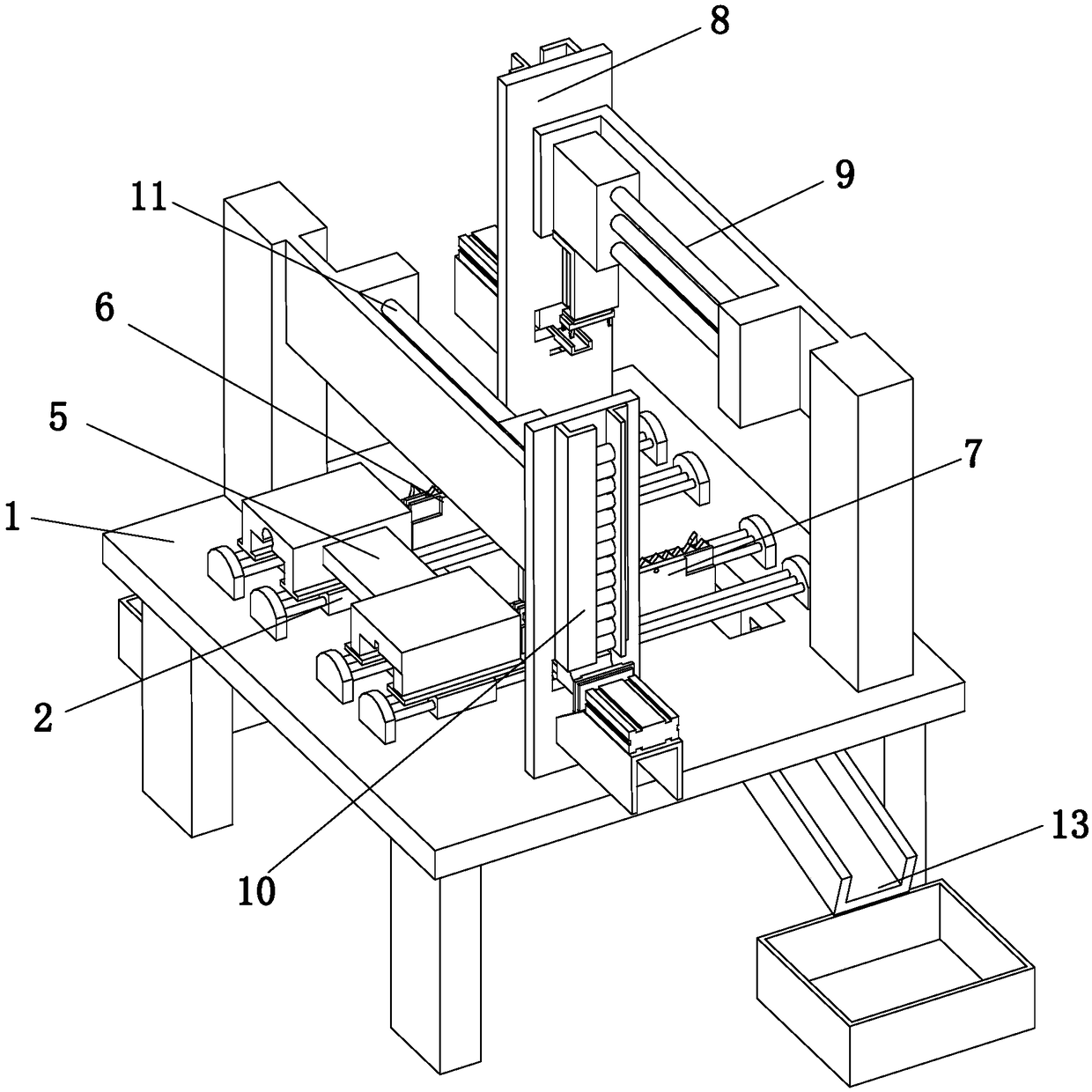

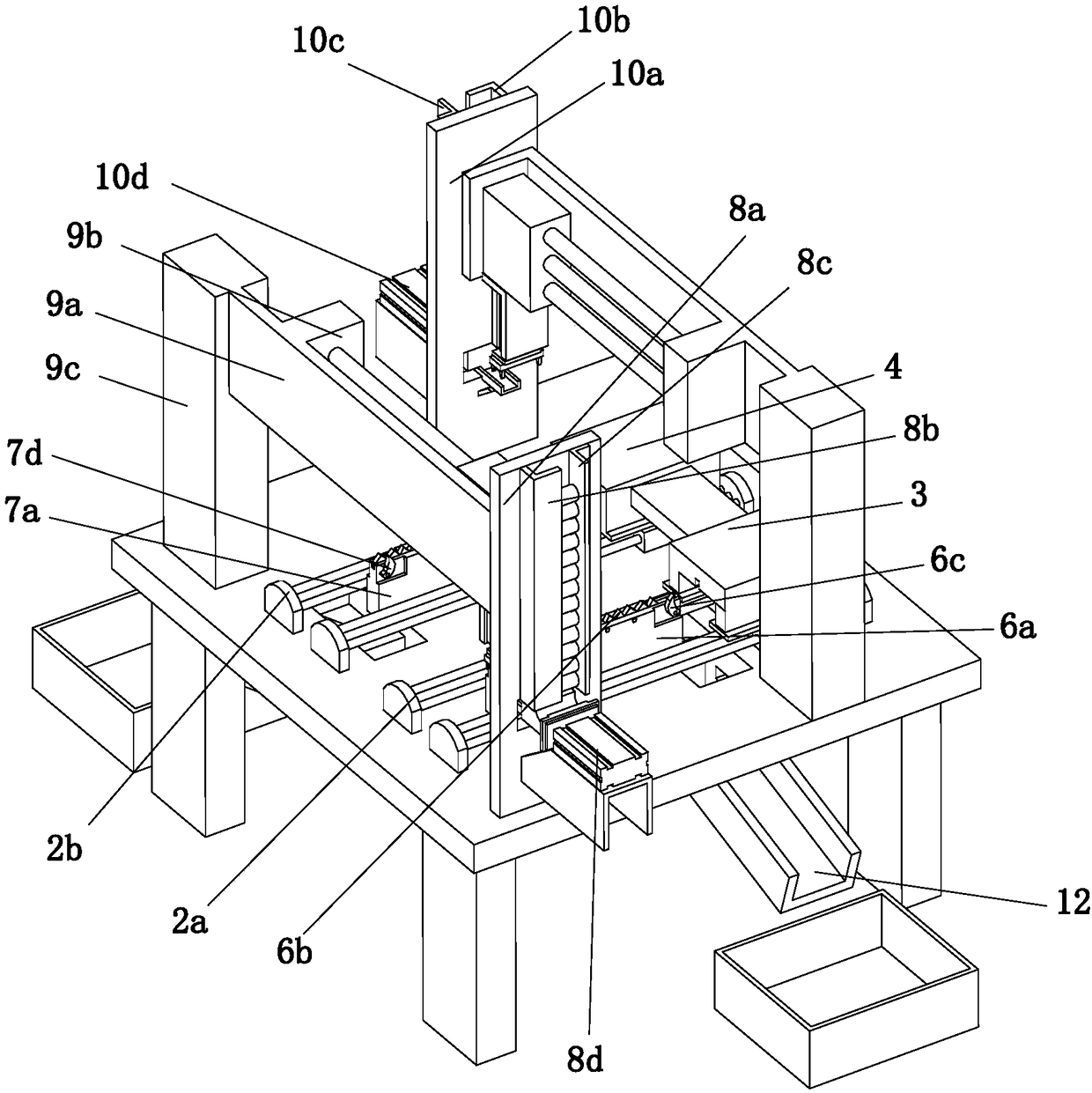

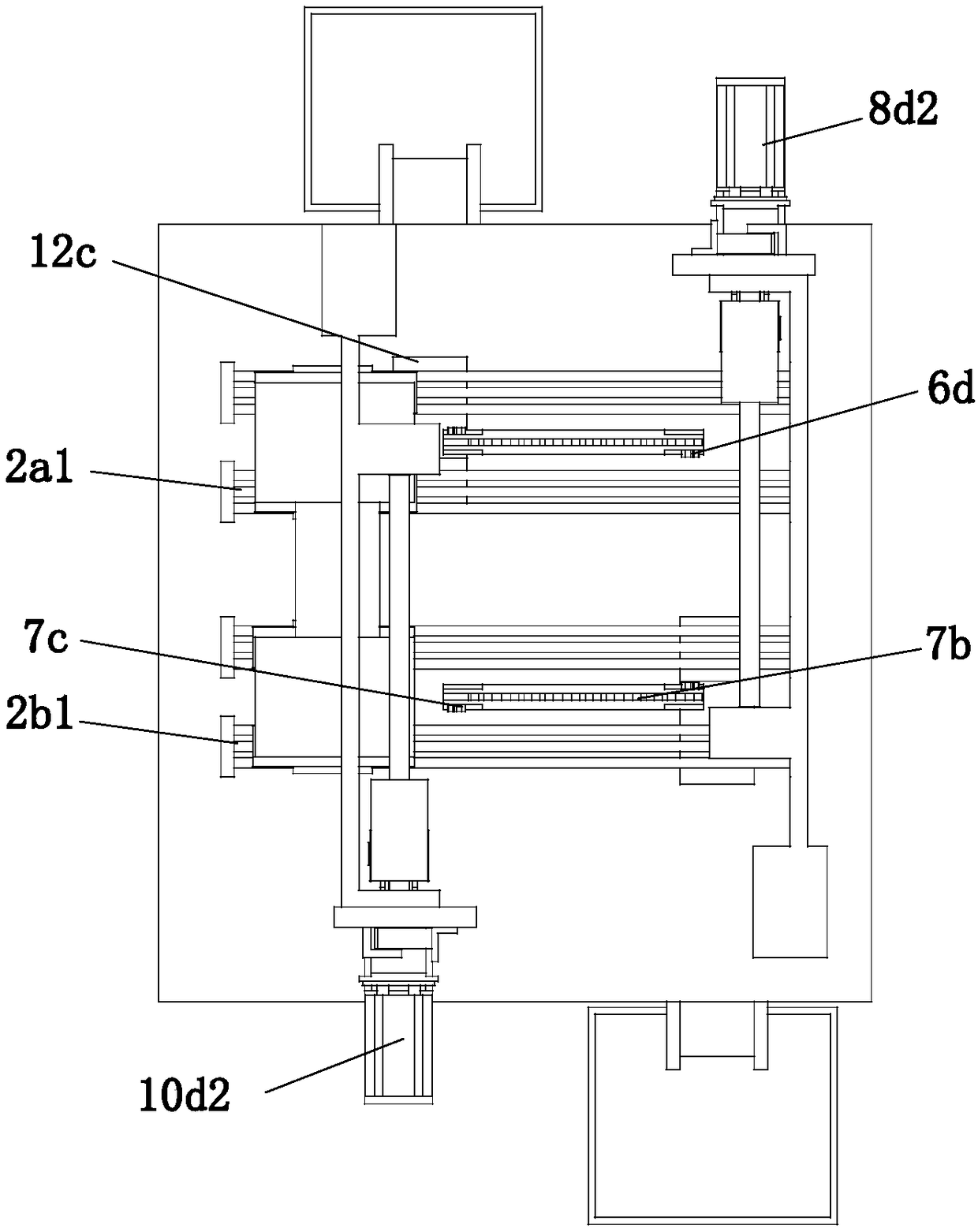

[0037] refer to Figure 1 to Figure 11 The cylinder lock automatic slotting machine shown includes a workbench 1 arranged horizontally, the top of the workbench 1 is provided with a slotting mechanism 2 arranged along its length direction, and the slotting mechanism 2 includes a The top of the first driving device 2a and the second driving device 2b arranged along its length direction, the tops of the first driving device 2a and the second driving device 2b are respectively provided with the first bearing block 3 and the first bearing block 3 fixedly connected with it. Two bearing blocks 4, a connecting block 5 is arranged between the first bearing block 3 and the second bearing block 4, and the two ends of the connecting block 5 are respectively fixedly connected with the first bearing block 3 and the second bearing block 4, The first driving device 2a and the second driving device 2b can respectively drive the first bearing block 3 and the second bearing block 4 to reciproca...

Embodiment 2

[0057] The grooving process of the automatic grooving machine for the lock cylinder includes the following steps:

[0058] Step 1. Stack the cylinders to be slotted in the first feeding device 8 and the second feeding device 10 respectively;

[0059]Step 2, the first transfer device 9 sends the lock cylinder in the first feeding device 8 to the first bearing block 3, and the first driving device 2a drives the first bearing block 3 to reciprocate along the length direction of the workbench 1 , the middle of the first driving device 2a is provided with a first slotting device 6 arranged along its length direction, the first bearing block 3 moves forward, and the first slotting device 6 slots the first cylinder , after the slotting is completed, when the first bearing block 3 returns, the first blocking assembly 6d on the first slotting device 6 collides with the contour edge of the lock cylinder, and the lock bladder is blanked into the first blanking device 12;

[0060] Step 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com