Visual positioning device of carton stack dismounting system

A visual positioning and carton technology, applied in the field of automation, can solve the problems of low degree of automation, difficult to design a plate disassembly mechanism, poor adaptability, etc., to achieve the effect of improving work efficiency and reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

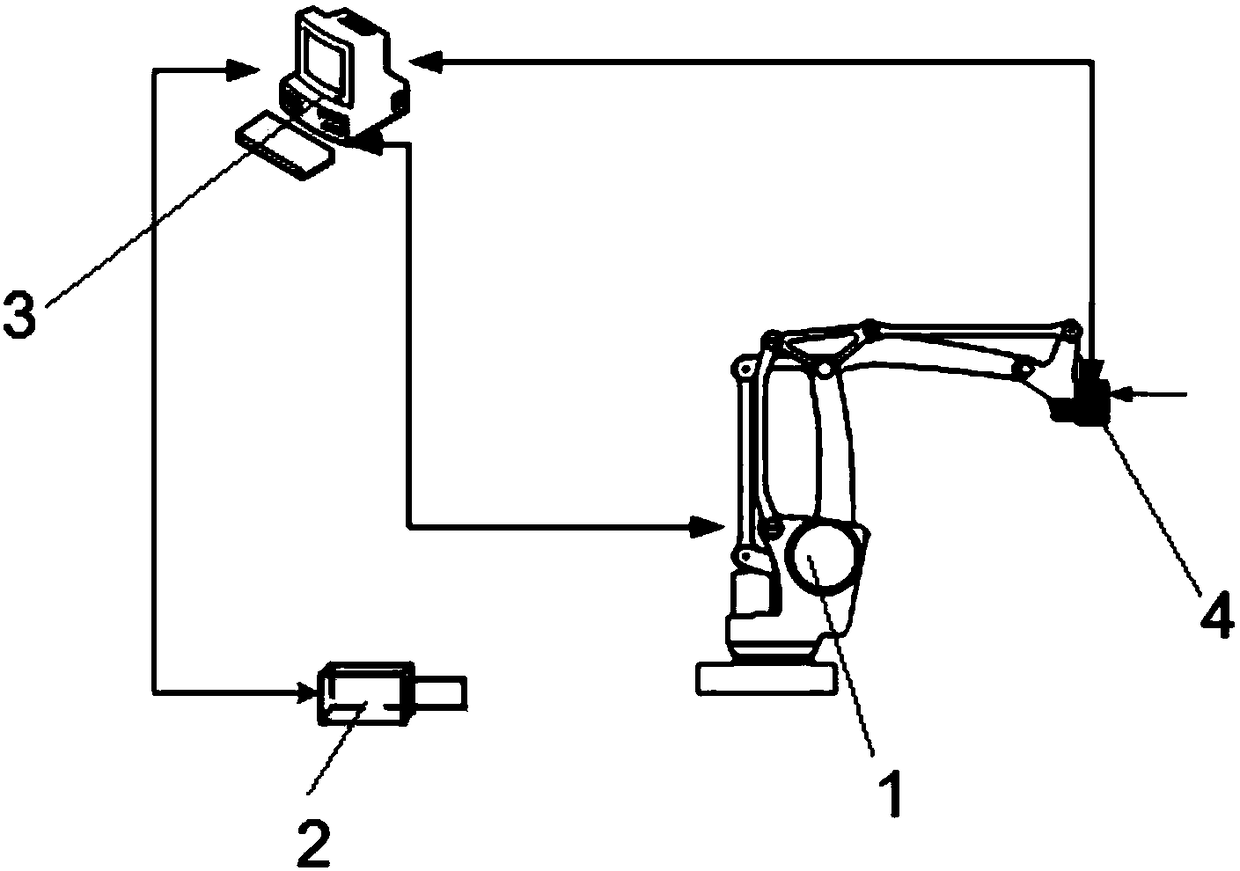

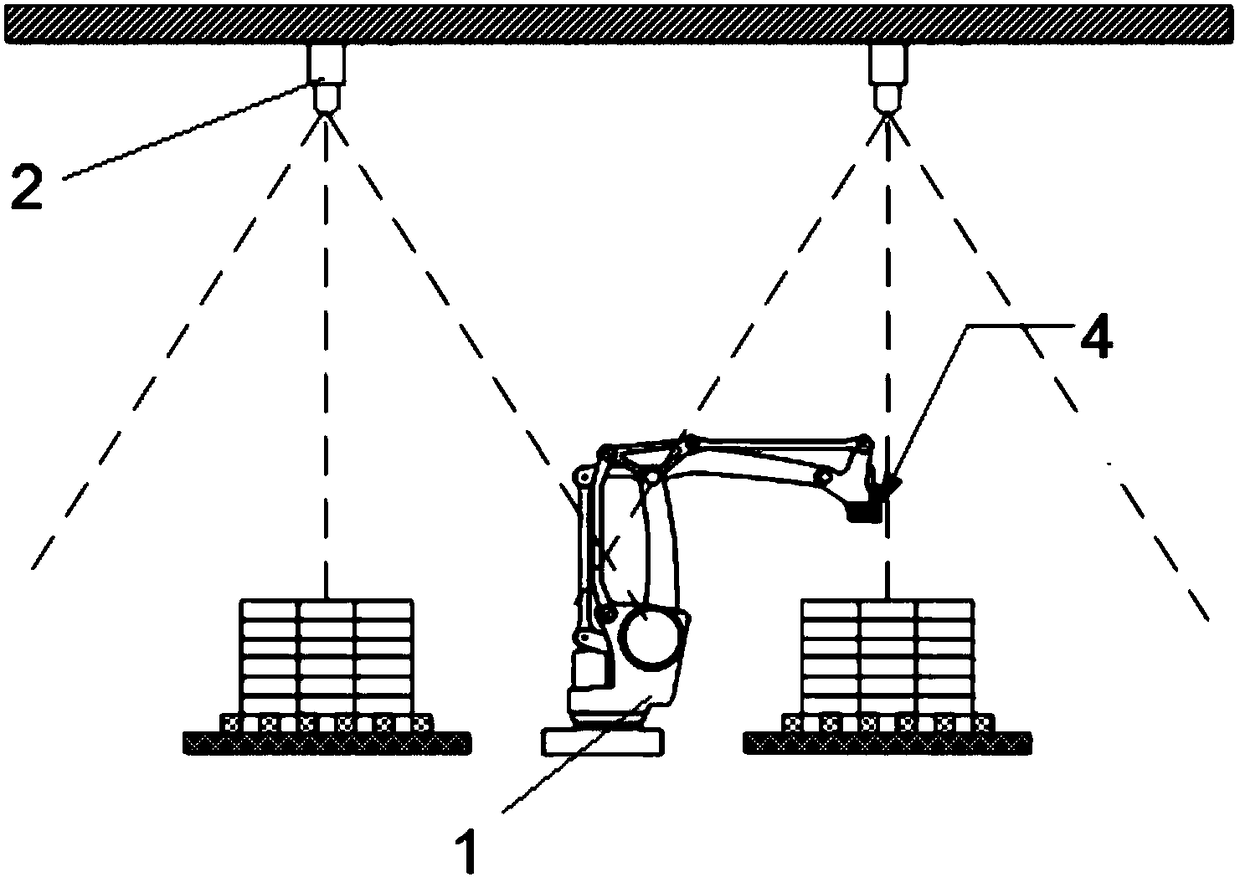

[0021] see Figure 1-2 , a visual positioning device for a carton stacking and dismantling system, having:

[0022] Robot module and vision positioning module;

[0023] The robot module includes a destacking robot arm 1;

[0024] The visual localization module has:

[0025] Industrial camera 2, photographing the stacking type and material plane position information of the stack to be disassembled;

[0026] The displacement sensor 4 is arranged on the unstacking robot arm 1, and is used to obtain the distance information from the unstacking robot arm to the material plane;

[0027] The industrial computer 3 is connected with the unstacking robot 1, the industrial camera 2 and the displacement sensor 4 through a circuit, receives dat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com