Port logistics container structure

A container and logistics technology, applied in the field of port logistics container structure, can solve the problems of damaged goods, lack of buffer protection structure of containers, increased transportation costs, etc., to achieve the effect of saving space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

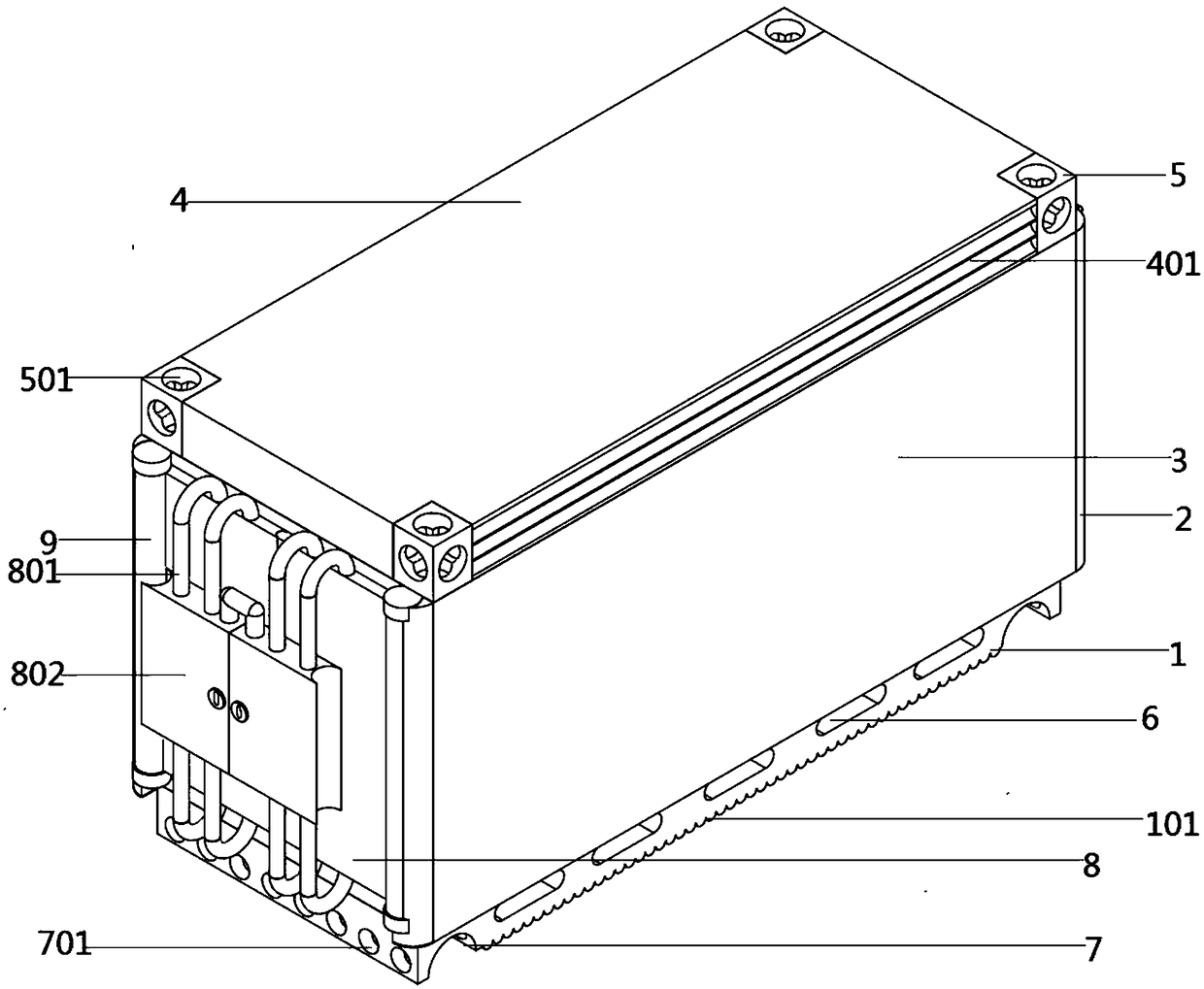

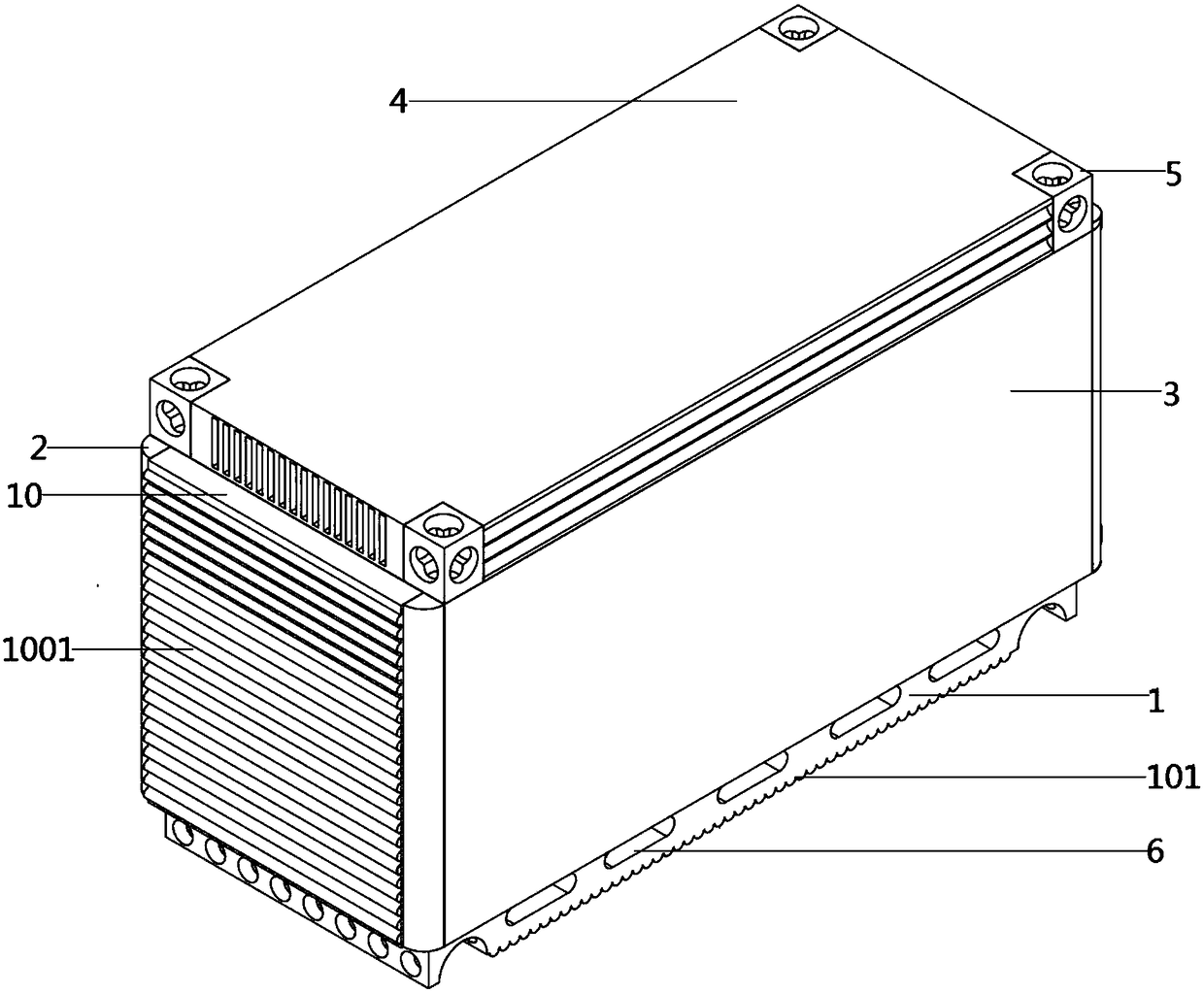

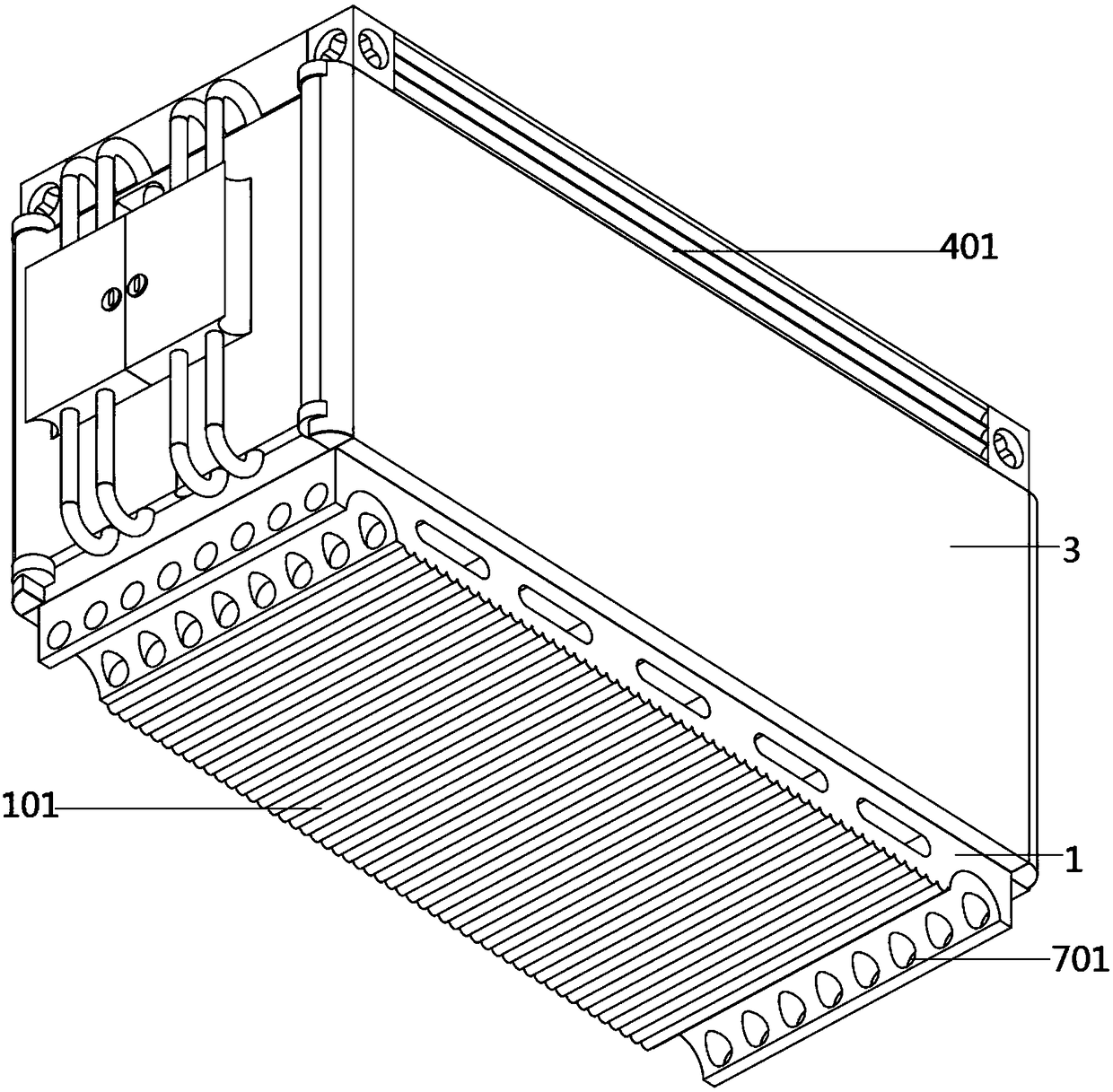

[0036] As attached figure 1 Attached Picture 12 Shown:

[0037] The present invention provides a port logistics container structure, which includes a bottom plate 1, a strengthening column 2, a side box plate 3, a top plate 4, a lifting knot 5, a jack 6, a fixing slot 7, a box door 8, a hinge 9, a front baffle 10, and inner Push plate 11, sliding groove 12, pulley 13, anti-skid column 101, plate groove 301, wire groove 401, connecting hole 501, fixing hole 701, sleeve rod 801, lock 802, buffer layer 1001, handle groove 1101, screw screw drive Group 1102 and limit block 1103; the top four corners of the bottom plate 1 are vertically connected with four reinforcing columns 2, and the two long sides of the reinforcing columns 2 are all sealed and connected with a rectangular side box plate 3, and two A front baffle 10 is fixedly connected between the reinforcing columns 2 on the short sides of the front ends; the top of the front baffle 10 and the side box plate 3 is covered with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com