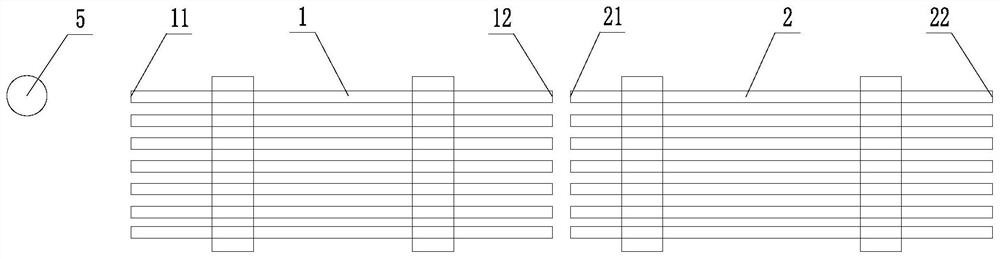

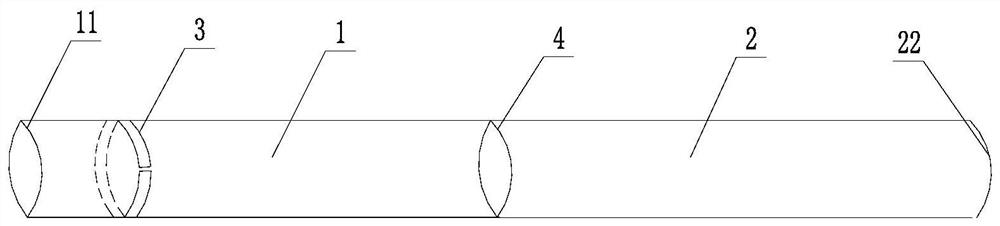

Welded injection-production casing and installation method for underground salt cavern gas storage

An installation method and welding technology, which is applied in the direction of casing, welding equipment, welding equipment, etc., can solve problems such as unsatisfactory, loose threaded connections, and affecting the air tightness of the wellbore, so as to reduce gushing, reduce costs, and reduce corrosion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

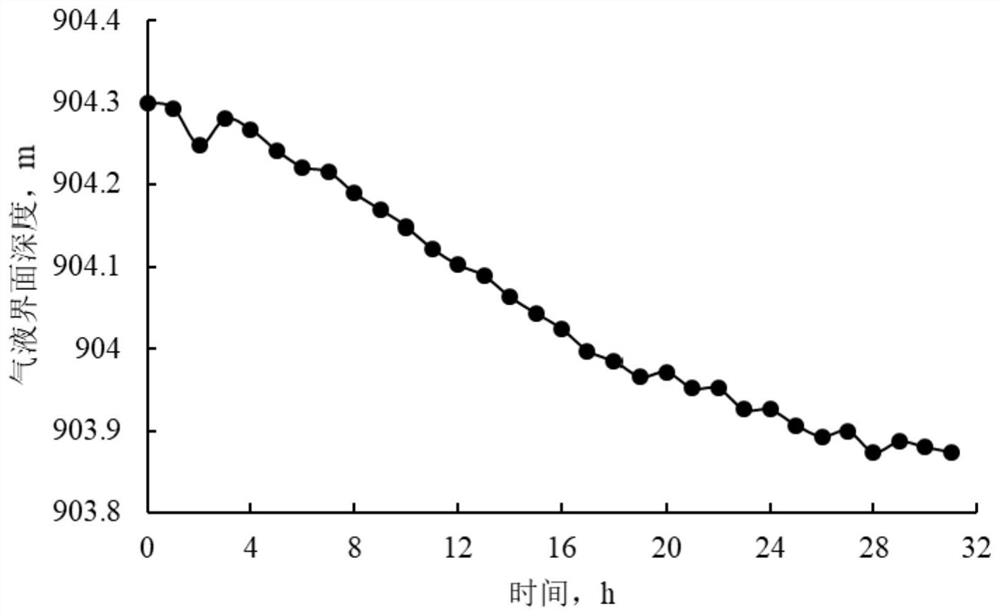

[0033] The salt deposits in the Jintan area were developed at the end of the deposition of the Funing Formation in the Zhixiqiao Sag, and belonged to limited salt lake deposits in the shrinking stage of the lake basin, with a salt-bearing area of 60.5 km 2 . The area where the underground salt cavern gas storage is located is moderately buried, with a top depth of 808.6m to 1098.95m. The salt layer is well developed, with a thickness of 143m to 173m, and the distribution is stable. At present, there are 17 wells for the salt cavern underground gas storage in this block , the entire block plans to build 71 salt cavern underground gas storage.

[0034] The following describes the present invention in detail in conjunction with specific examples, but does not limit the scope of the present invention.

[0035] Taking Well WL01 of a salt cavern gas storage in the Jintan Salt Basin as an example to illustrate the application of welded casing in the salt cavern gas storage, and se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com