Preparation method of high-reliability radial-flow supercharger turbine impeller

A turbocharger turbine and turbine impeller technology, which is applied to mechanical equipment, machines/engines, blade support elements, etc., can solve the problems of poor forming quality of turbine impeller blades, poor blade shape quality, small flow space, etc., and achieve improvement Effects of reliability and manufacturing yield, improvement of strength and reliability, and assurance of molding integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0017] The present invention will be described in detail below with reference to the accompanying drawings and examples.

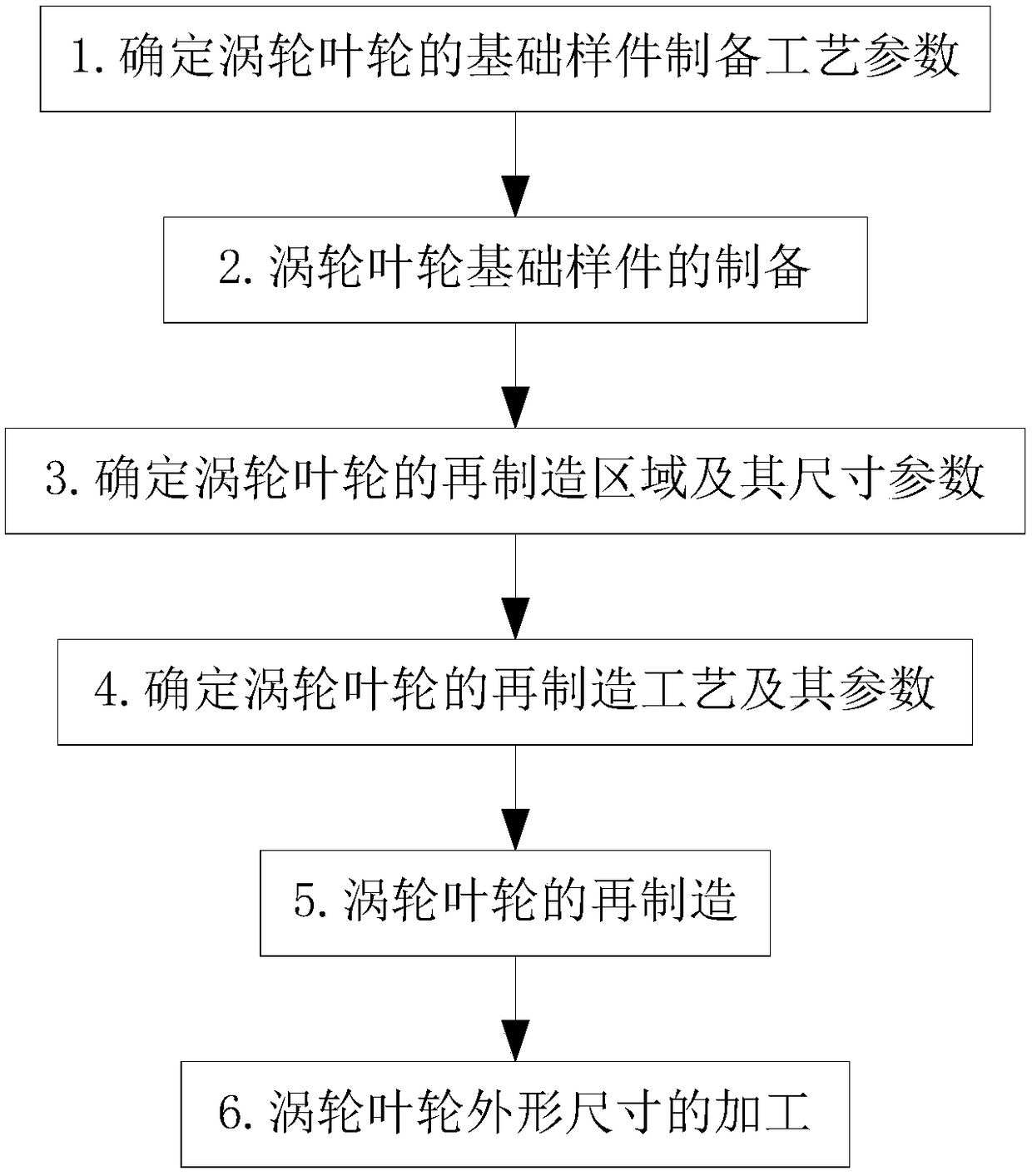

[0018] A high-reliability radial supercharger turbine impeller preparation method, such as figure 1 shown, including the following steps:

[0019] a. Determine the process parameters of the basic sample preparation of the turbine impeller: the basic sample preparation of the turbine impeller adopts the centrifugal casting molding process, and according to the structural parameters of the radial turbocharger turbine impeller, reasonably determine the centrifugal casting that can ensure the quality of the turbine impeller blade molding Process parameters.

[0020] b. Preparation of the basic sample of the turbine impeller: the centrifugal casting molding process is adopted, and the basic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com