Mechanical sealing device and application thereof

A mechanical sealing device and technology of the sealing device, which are applied in the direction of engine sealing, mechanical equipment, engine components, etc., can solve the problems of short service life, uneven force on the sealing surface, fragile main sealing surface, etc., to improve the use of Longevity, reduced friction, and the effect of small frictional resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to describe the technical content of the present invention more clearly, further description will be given below in conjunction with specific embodiments.

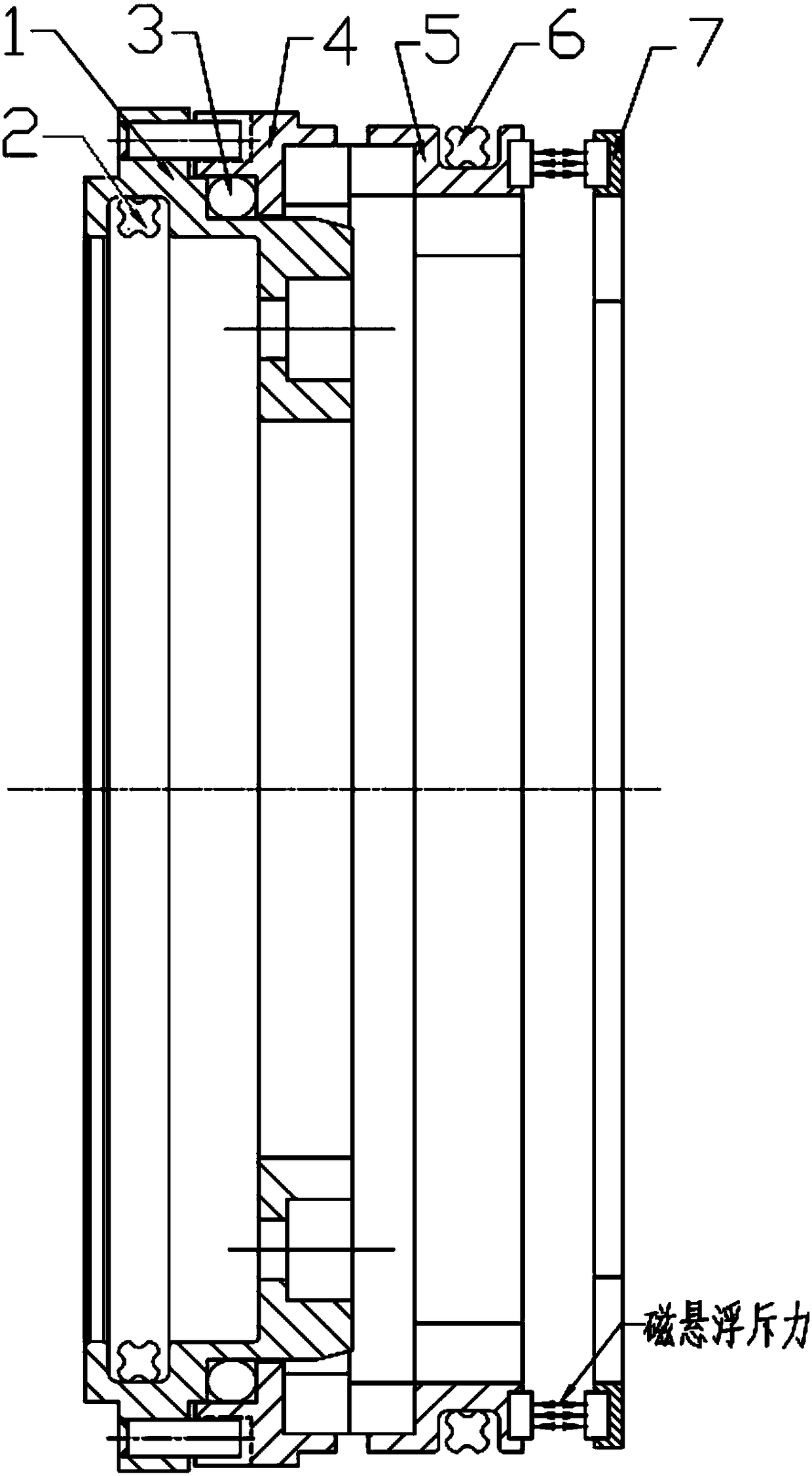

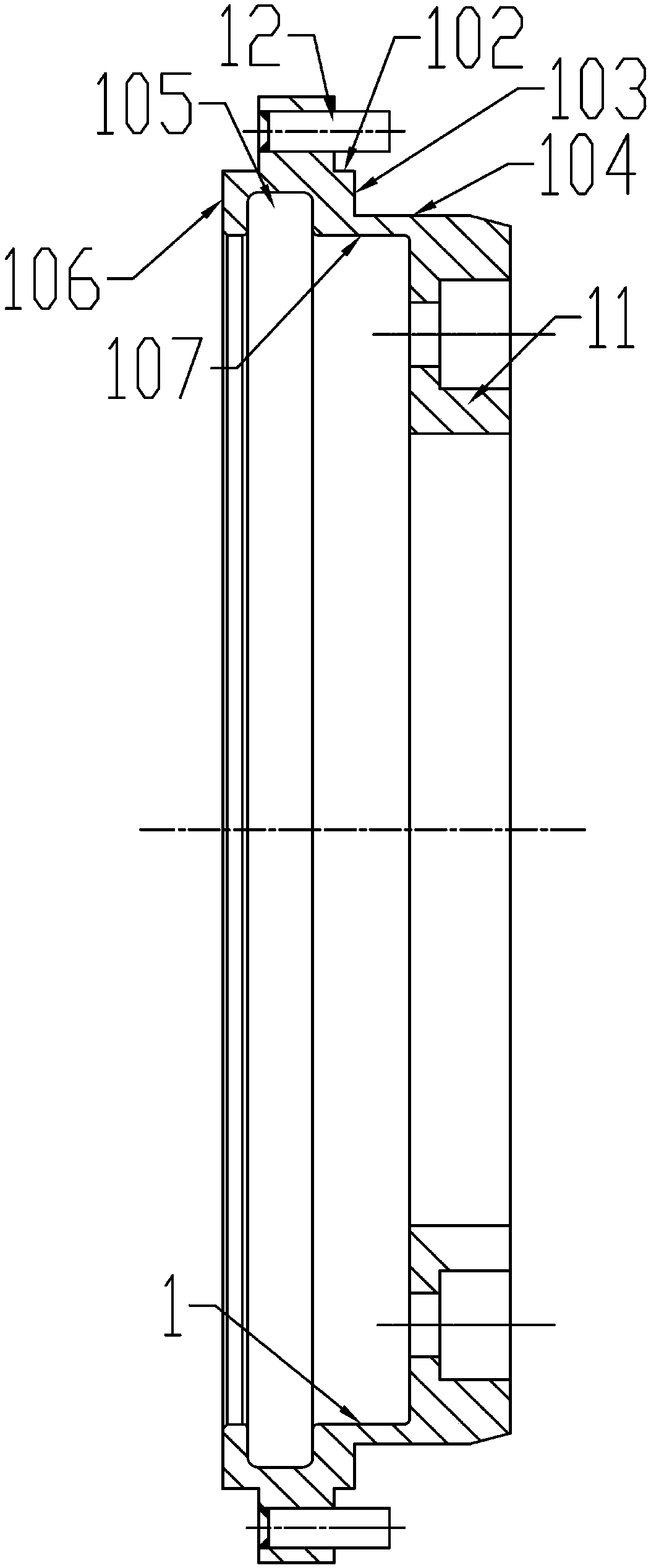

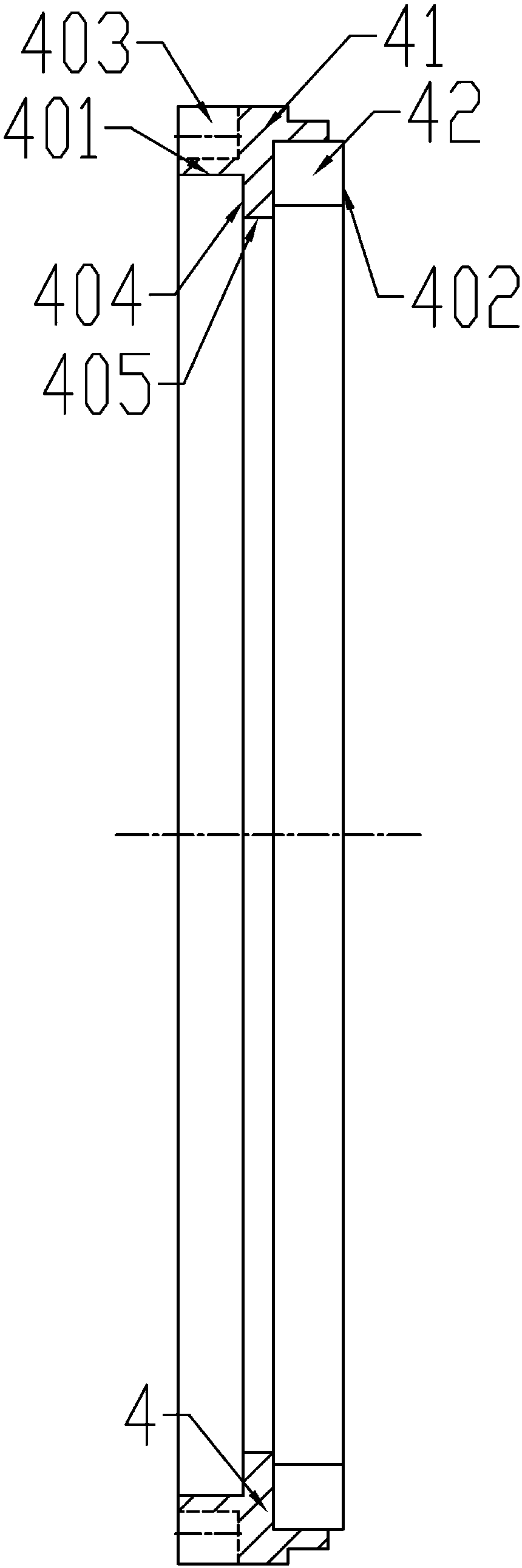

[0034] like figure 1 , 2 , 5, and 7 show an embodiment of a mechanical sealing device provided by the present invention. The mechanical sealing device includes: a positioning sleeve 1, including a positioning sleeve body 11, an outer mounting surface 104, and a shaft for fitting the roller shaft to be sealed. The inner mounting surface 107, and the first sealing groove 105 arranged on the inner mounting surface 107 and equipped with the first sealing ring 2 inside, through the first sealing ring 2, the positioning sleeve 1 and the to-be The sealed roller shaft forms the first static sealing body; the dynamic friction ring 4 includes an assembly surface 401 forming a second sealing groove with the outer mounting surface of the positioning sleeve, and a first dynamic sealing surface protruding axially along ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com