A method for detecting the qualified permeability of cast-type wire rope joints

A detection method and wire rope technology, applied in measuring devices, instruments, etc., can solve problems such as lack of detection standards, achieve the effect of improving breaking force and ensuring product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

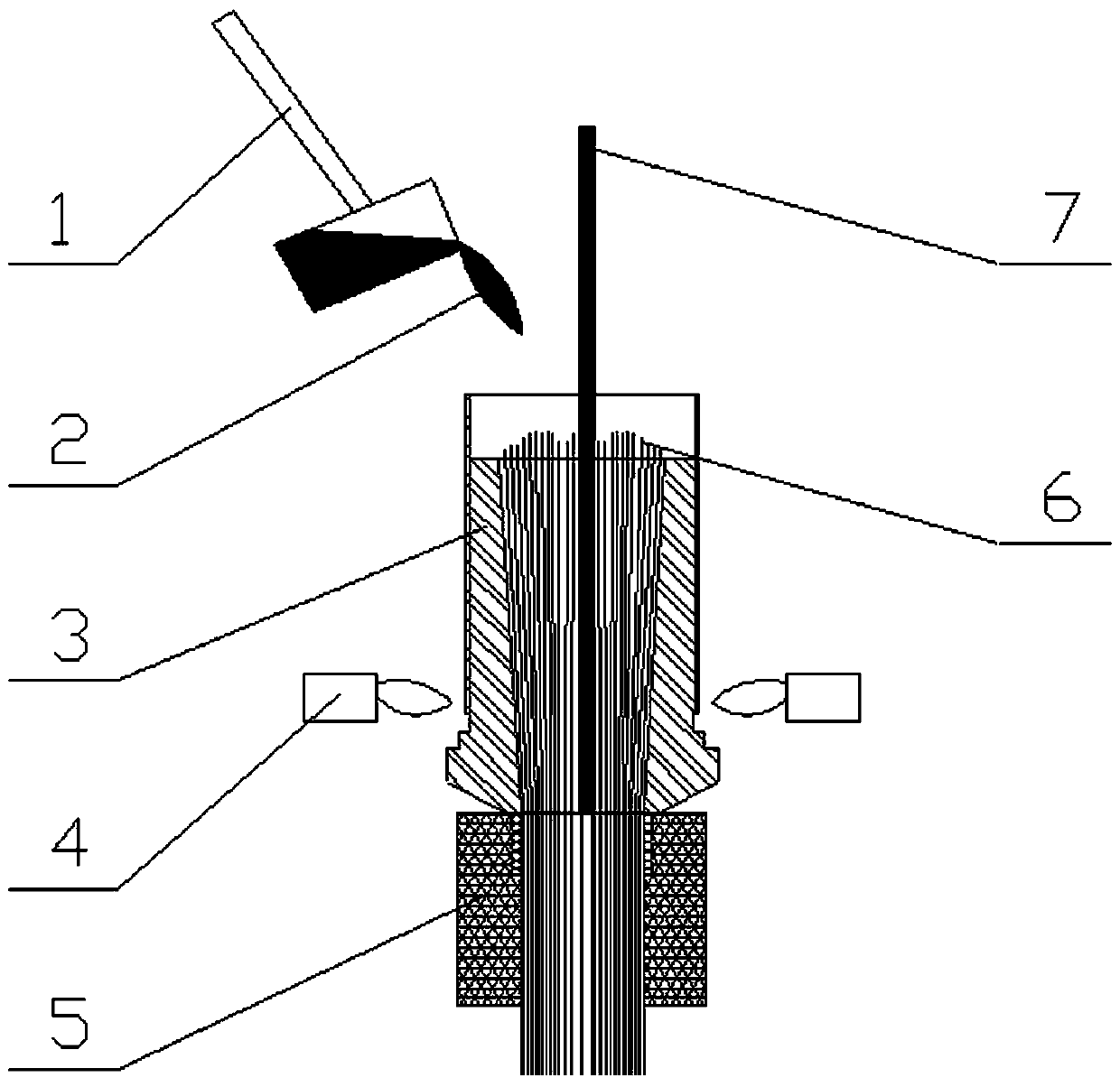

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

[0019] With reference to the accompanying drawings, a qualified detection method for the permeability of a cast-type wire rope joint: it includes the following steps:

[0020] Step 1. Assemble the end of the wire rope 6 into the interior of the joint 3;

[0021] Step 2, wrapping the wire rope 6 at the bottom of the joint 3 with a heat insulating layer 5;

[0022] Step 3. Insert the detection steel wire 7 vertically from the center of the joint 3 to the bottom of the joint 3, pull the detection steel wire 7 upwards, and confirm that the detection steel wire 7 can be pulled out freely from the joint 3;

[0023] Step 4, preheating joint 3 and wire rope 6, the preheating temperature is 250°C;

[0024] Step 5, pour the solder 2 into the gap between the joint 3 and the steel wire rope 6;

[0025] Step 6: Heating the joint 3 and pulling the detect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com