A test method for dynamic pressure air bearing on-orbit friction torque

A technology of dynamic pressure air bearing and friction torque, which is applied in the field of inertial instrument parameter measurement, can solve the problems of low motor speed, inability to know the speed information of motor dynamic pressure air bearing, and inability to obtain counter electromotive force signal correctly, so as to reduce the cost of experiments, Simple process and strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

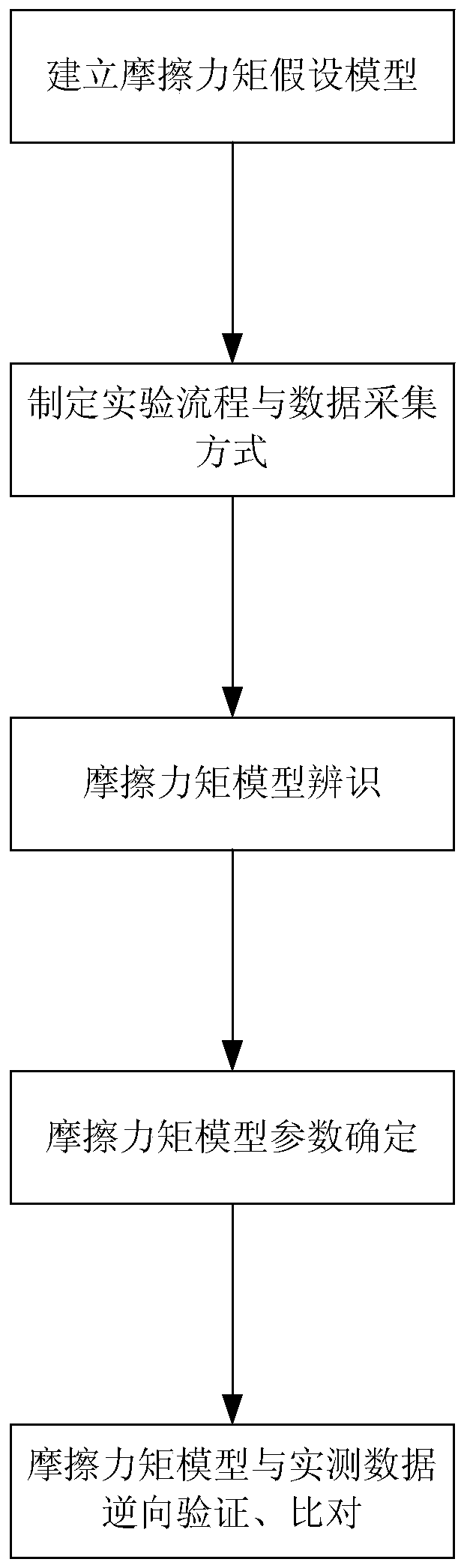

[0077] Concrete steps of the present invention are as follows:

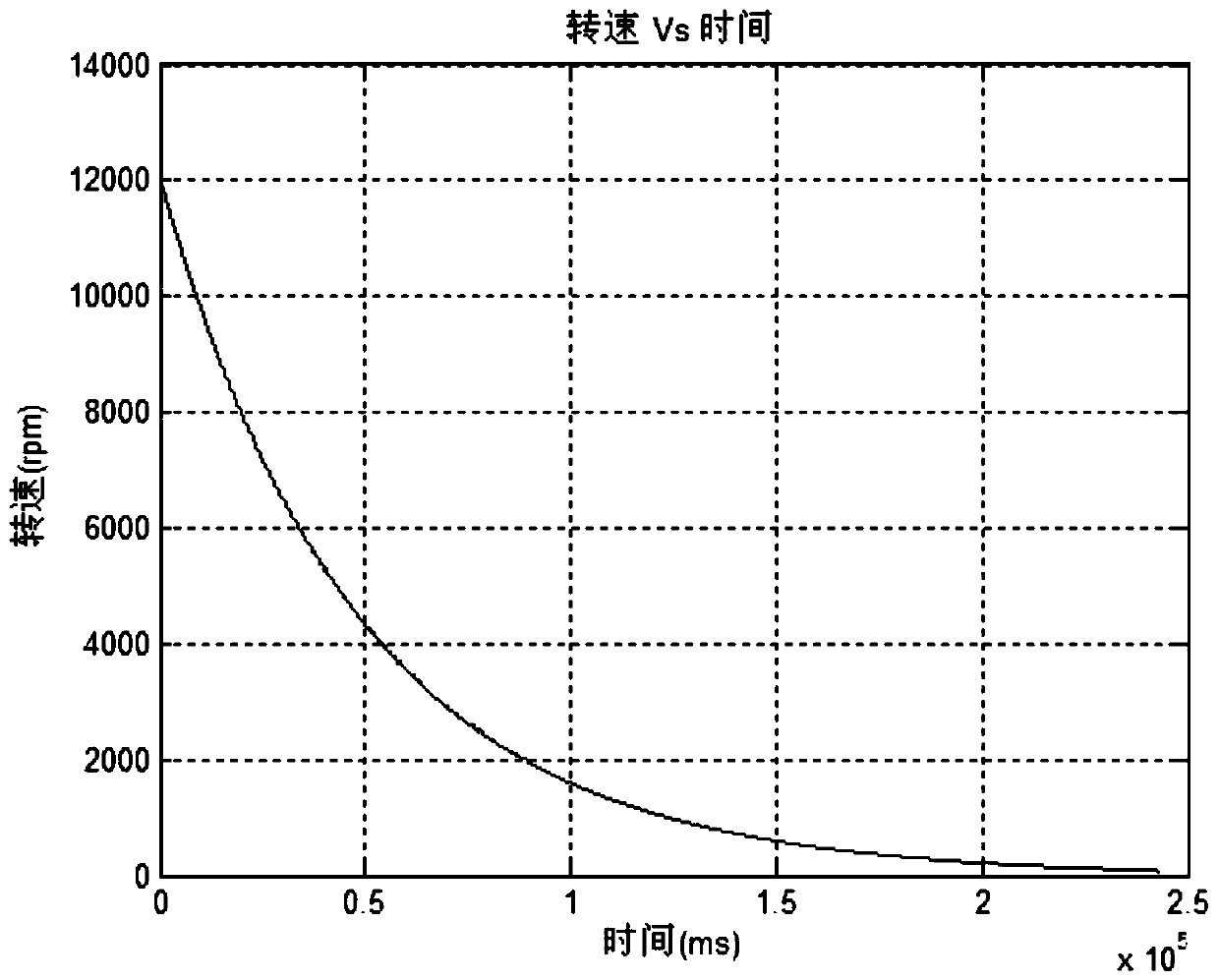

[0078] (1) Establish the mathematical model M(ω)=α of the rotational speed ω of the dynamic pressure air bearing and the frictional moment M of the dynamic pressure air bearing n ω n +α n-1 ω n-1 +...+α 1 ω,n=1,2,...,10;

[0079] (2) According to the dynamic equation of the permanent magnet synchronous motor of the dynamic pressure air bearing and the mathematical model established in step (1), formulate the friction torque test experimental process and data collection method;

[0080] The dynamic equation of the permanent magnet synchronous motor with dynamic pressure air bearing is:

[0081]

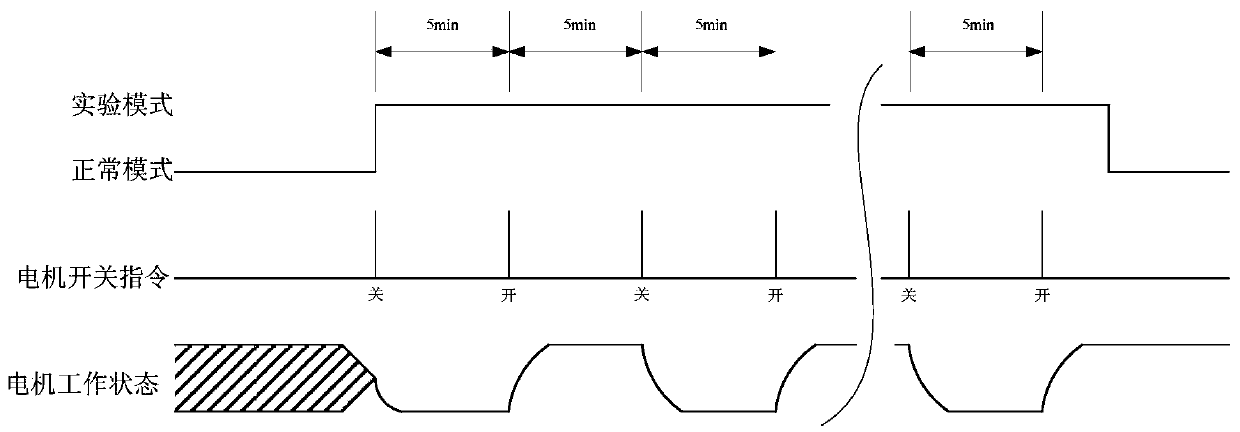

[0082] The experimental process and data collection method of friction torque test are as follows:

[0083] The experimental process of friction torque test is: turn on the permanent magnet synchronous motor, wait for the permanent magnet synchronous motor to run for 5 minutes, turn off the permanent magnet synch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com