Moveable plutonium powder sampling device

A sampling device and powder technology, applied in the sampling device and other directions, can solve the problems of smooth surface of the stainless steel sampling bottle, difficult to hold, transport and open the cap, hidden danger of material spilling, lengthening the length of the sampler, etc., so as to reduce the cost of radiation protection, The effect of shortening the sampling operation time and increasing the operable space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

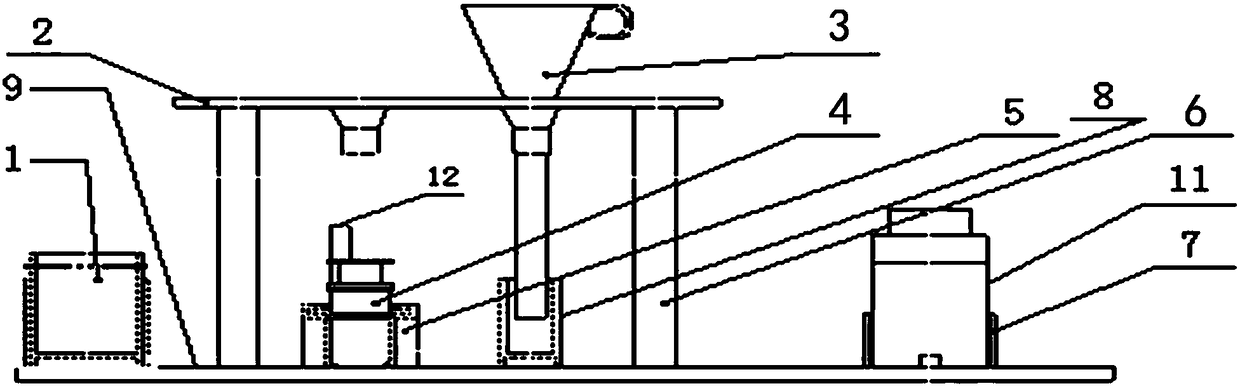

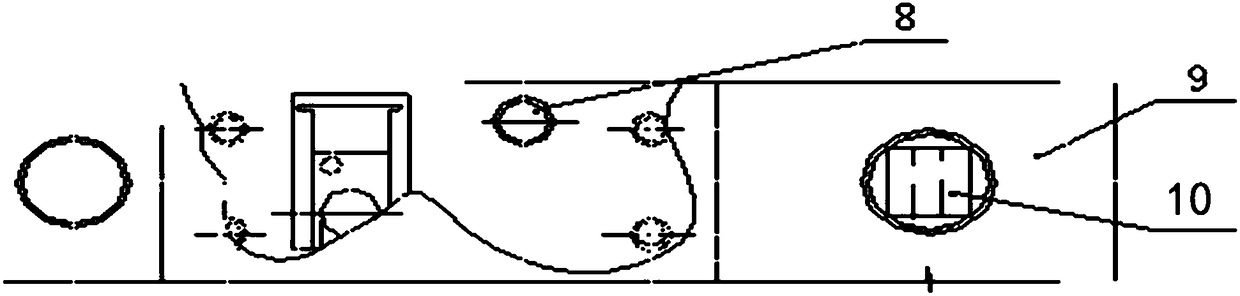

[0041] Such as figure 1 , figure 2 A movable plutonium powder sampling device shown includes a sampling platform 9 , sampling forceps, a funnel 3 , a sampling bottle 4 , and a running rabbit 11 .

[0042] The sampling platform 9 is located in the sampling cabinet and can move in the sampling cabinet. Sampling platform 9 adopts thickened metal material, to guarantee stability.

[0043] A sampling tongs placement cup 1 is provided on the sampling platform 9 for placing the sampling tongs. The described sampling tongs place the cup 1 and the sampling platform 9 are welded and fixed to increase the weight of the sampling platform 9 and further ensure stability.

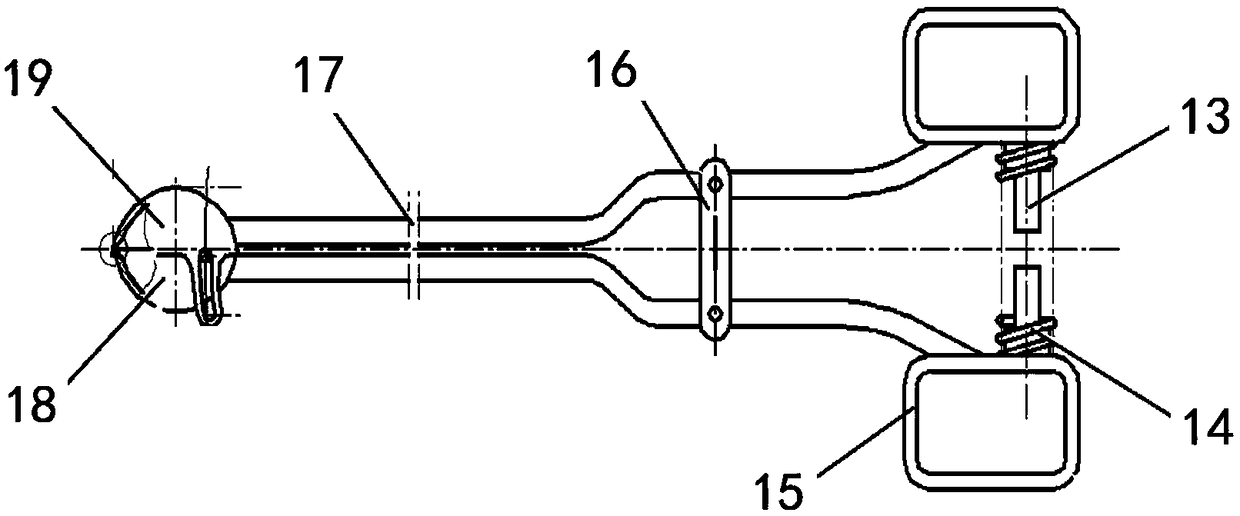

[0044] Such as image 3 , Figure 4 As shown, the sampling pliers include a clamping handle 15, a connecting rod 16 and a jaw. The clamp handle 15 and the jaws are opened...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com