Automatic circulation type material bin and control system thereof

An automatic circulation and silo technology, applied in the direction of conveyor control device, object stacking, object destacking, etc., can solve the problem of inability to accurately convey the transmission chain on the pallet, occupying a large space, servo motor or stepping motor output Value accumulation error and other problems, to achieve the effect of increasing the number of pallet tooling, simplifying the structural layout, and compensating for workpiece positioning errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below with reference to the accompanying drawings and several preferred embodiments.

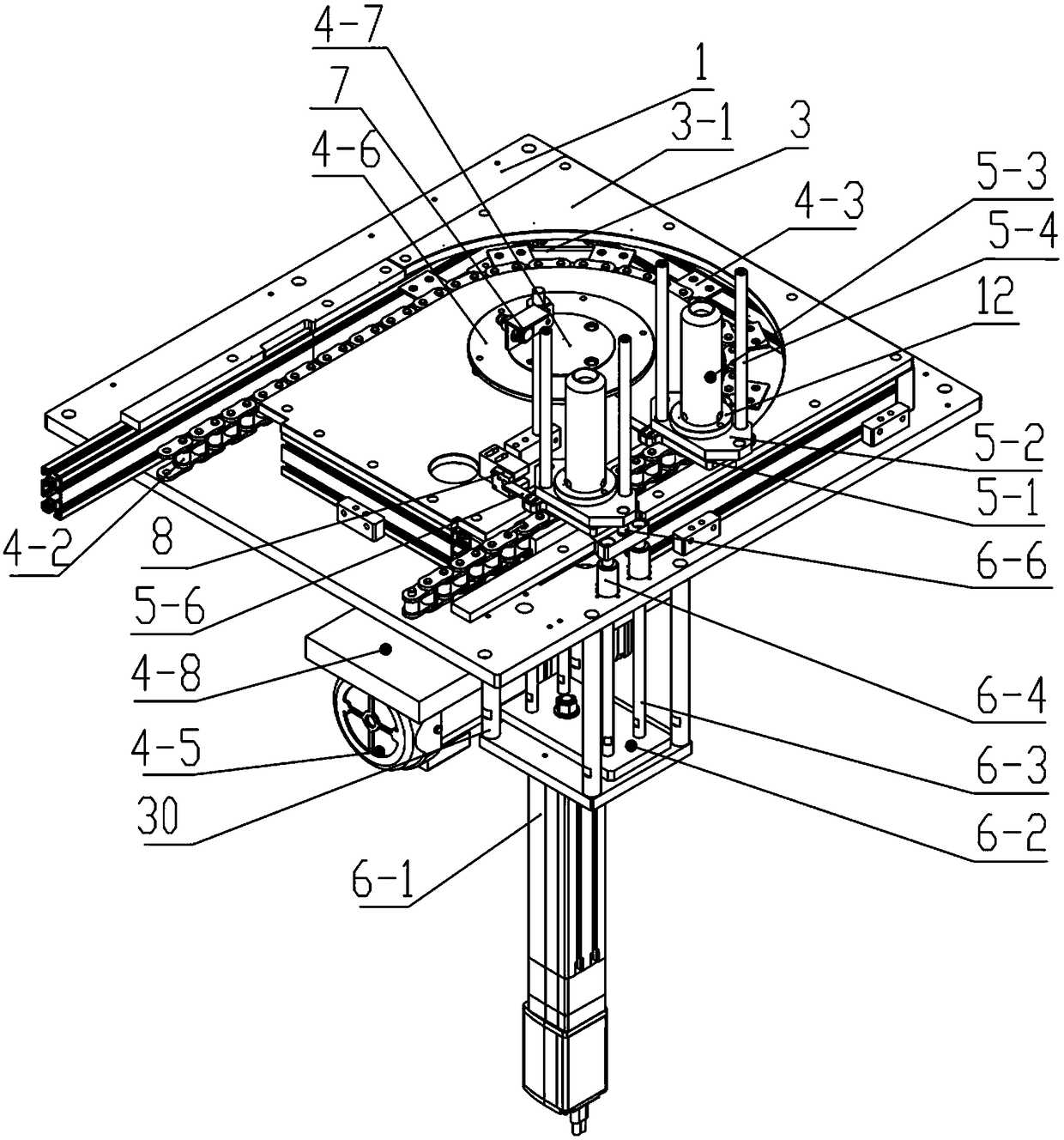

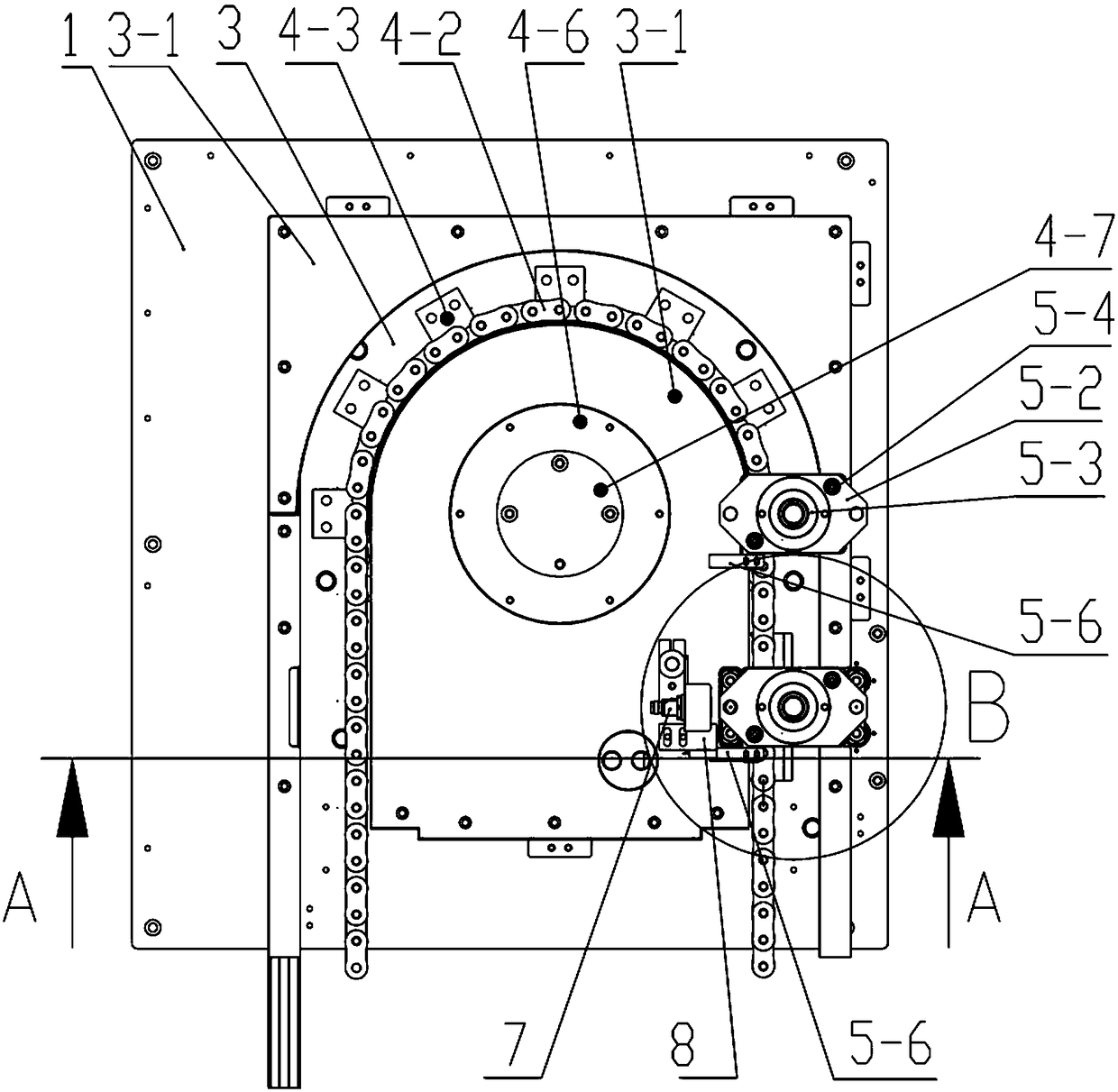

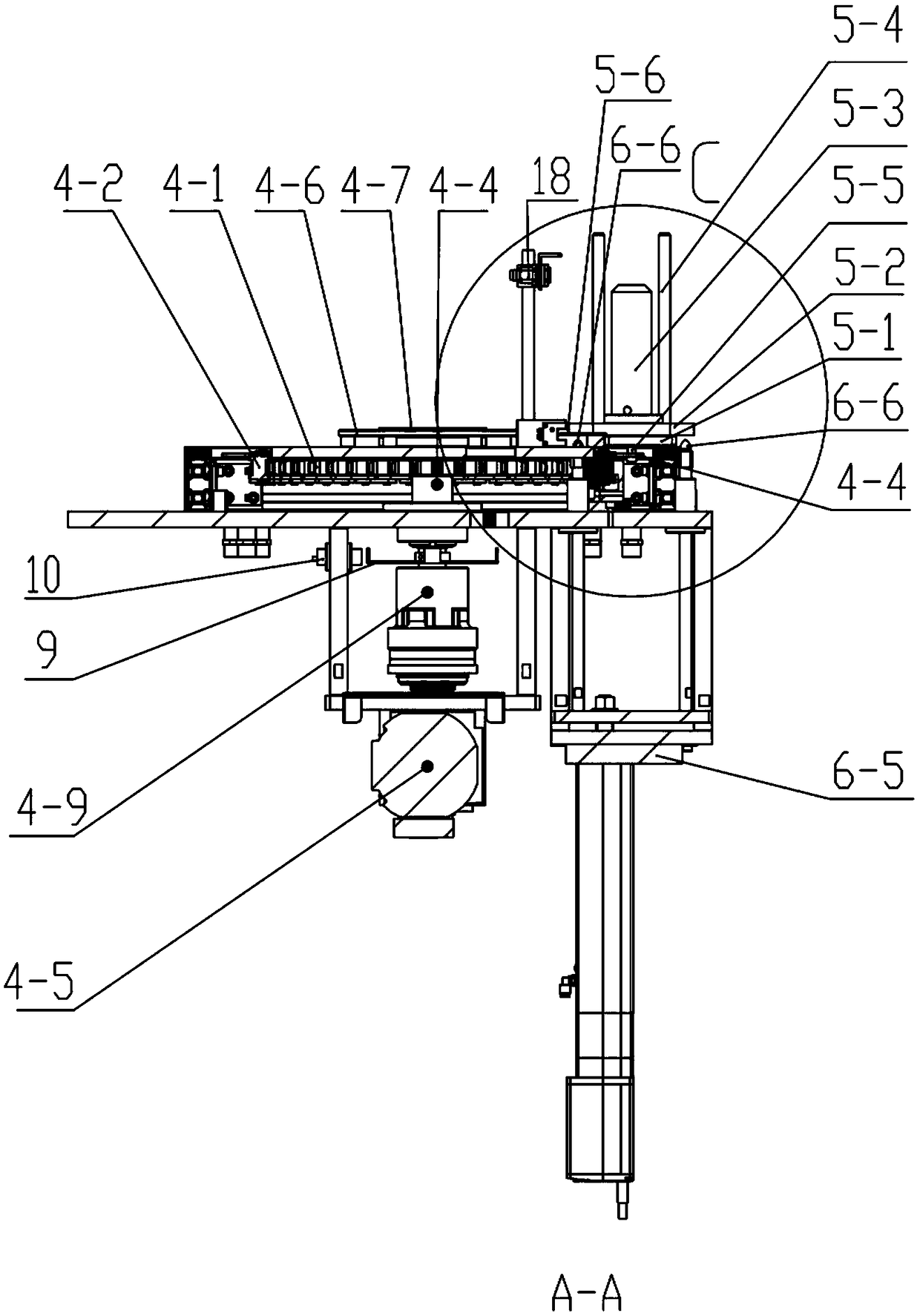

[0030] Such as Figure 1 to Figure 7As shown, a kind of automatic circulating silo, the structure comprises: reference plate 1, is arranged on the top of reference plate 1, is formed by the annular slideway 3 of metal plate, is arranged on the inside of annular slideway 3 and drives along it, The workpiece palletizing device that slides freely in the circular slideway 3 is driven by the chain, and the jacking drive device installed under the reference plate 1 and supporting the reference plate is used to lift the workpiece palletizing device. The inner ring of the circular track And the upper end surface of the outer ring is laid with wear strip 3-1. Wherein, the structure of the transmission device includes: a sprocket 4-1 installed on the inner side of the annular slideway 3 and located in the metal plate cavity, and a chain 4-2 ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com