Battery module bracket, battery module and battery pack

A technology of battery modules and battery packs, which is applied in the direction of battery/battery traction, battery/fuel cell control devices, battery pack components, etc., and can solve problems affecting the service life of battery packs, low space utilization, and large temperature differences between batteries, etc. problems, to achieve the effect of simple structure, improved service life, and reduced temperature difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

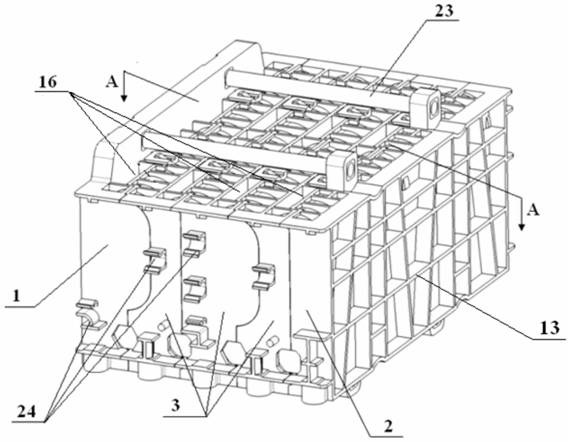

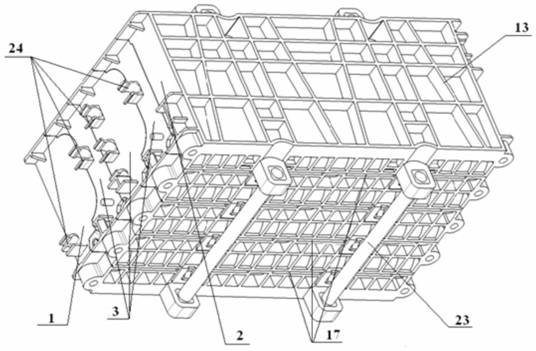

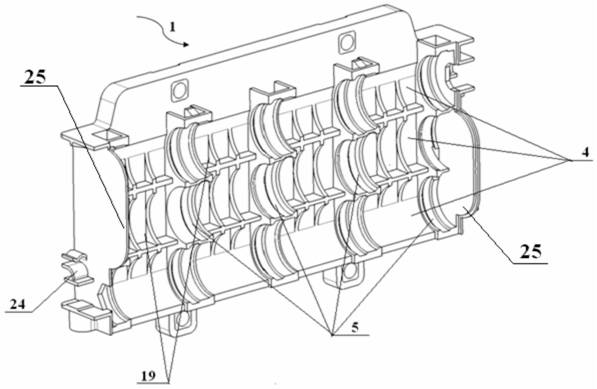

[0026] A battery module bracket, such as figure 1 , figure 2 As shown, it includes a left bracket 1, a right bracket 2 and three middle brackets 3;

[0027] As shown in Figure 3 (a), one side of the left bracket 1 is provided with three layers of first ventilation slots 4 that are curved in side view, and each layer of first ventilation slots 4 is provided with four first ventilation slots 4 that are curved in side view. A battery pack support slot 5, a first groove 19 is arranged in the first ventilation slot 4 of the left bracket 1, and the positions of the first battery pack support slots 5 provided on the first ventilation slot 4 of each layer are the same, and the first battery pack The arc diameter of the support groove 5 is matched with the outer diameter of the single battery in the corresponding battery pack, the arc diameter of the first ventilation slot 4 is larger than the arc diameter of the first battery pack support slot 5, and the arc diameter of the first ve...

Embodiment 2

[0032] A battery module bracket, the structure of which is similar to that of the battery module bracket in Embodiment 1, the difference is that the number of the intermediate brackets is five.

Embodiment 3

[0034] A battery module, including twelve groups of battery groups formed by connecting the same number of single cells in series, installing twelve groups of battery groups in the battery group installation channel in the battery module bracket in embodiment 1, twelve The battery packs are connected in series with each other, and the wiring harnesses of the twelve battery packs are clamped in the wire slots in the battery module bracket.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com