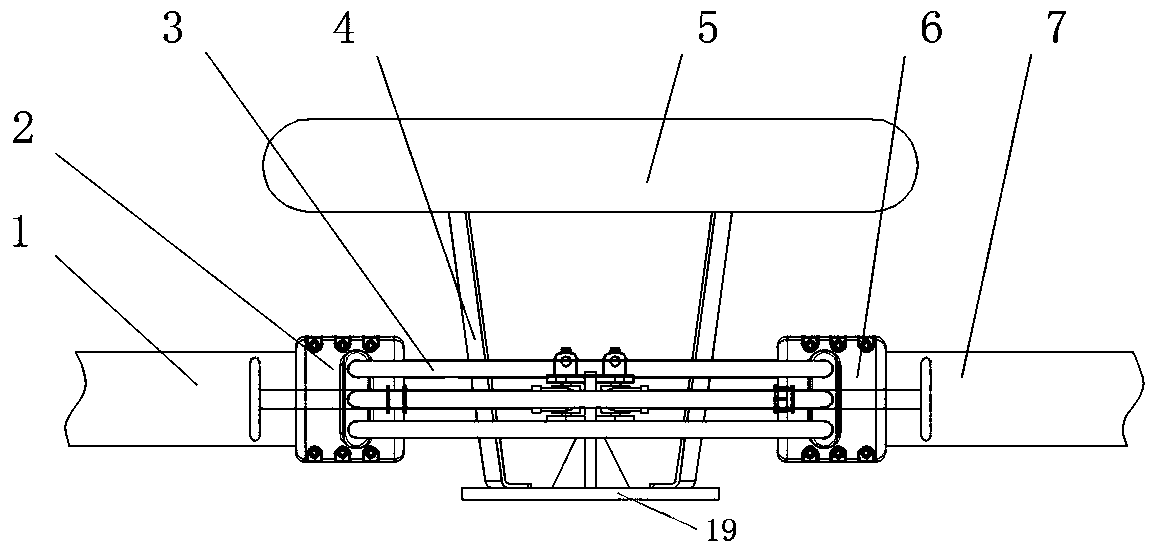

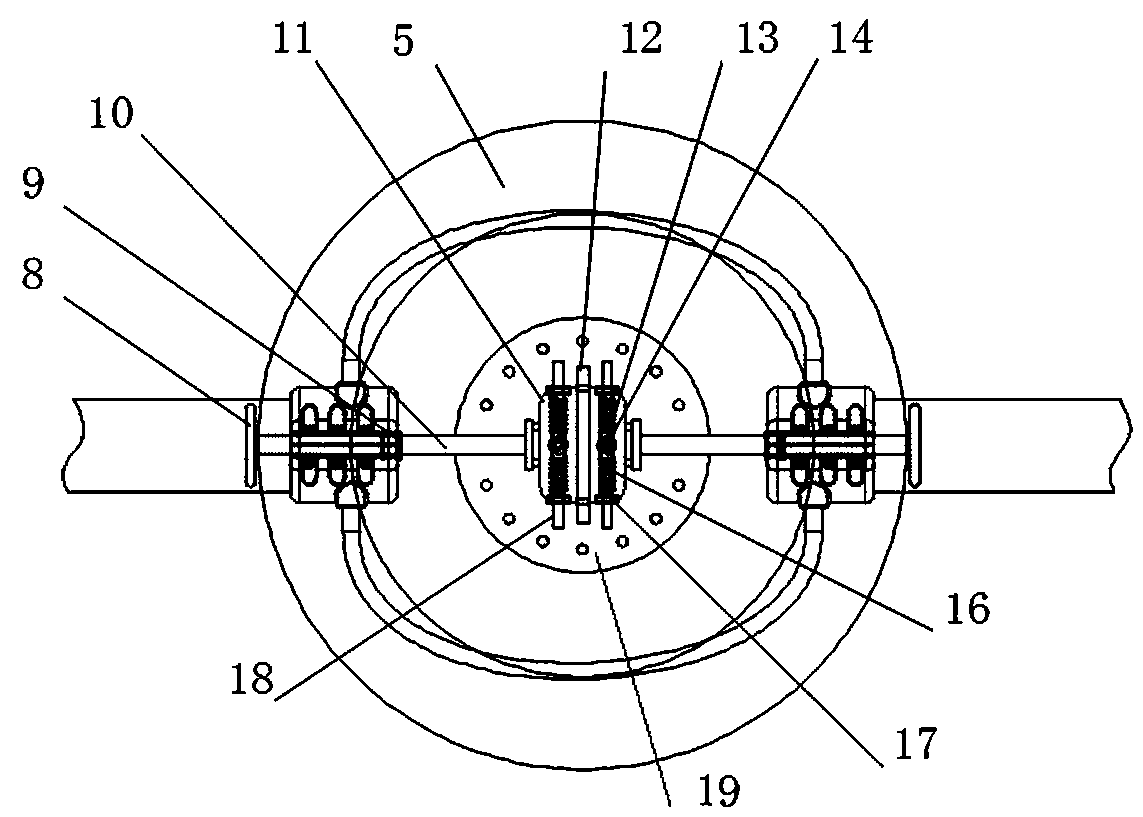

Tubular busbar support fitting

A technology for pipe busbars and fittings, which is applied in the installation of busbars, open busbar installations, electrical components, etc., can solve problems such as the inability to realize the displacement of pipe busbars, and achieve the effect of protecting safety and avoiding interaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

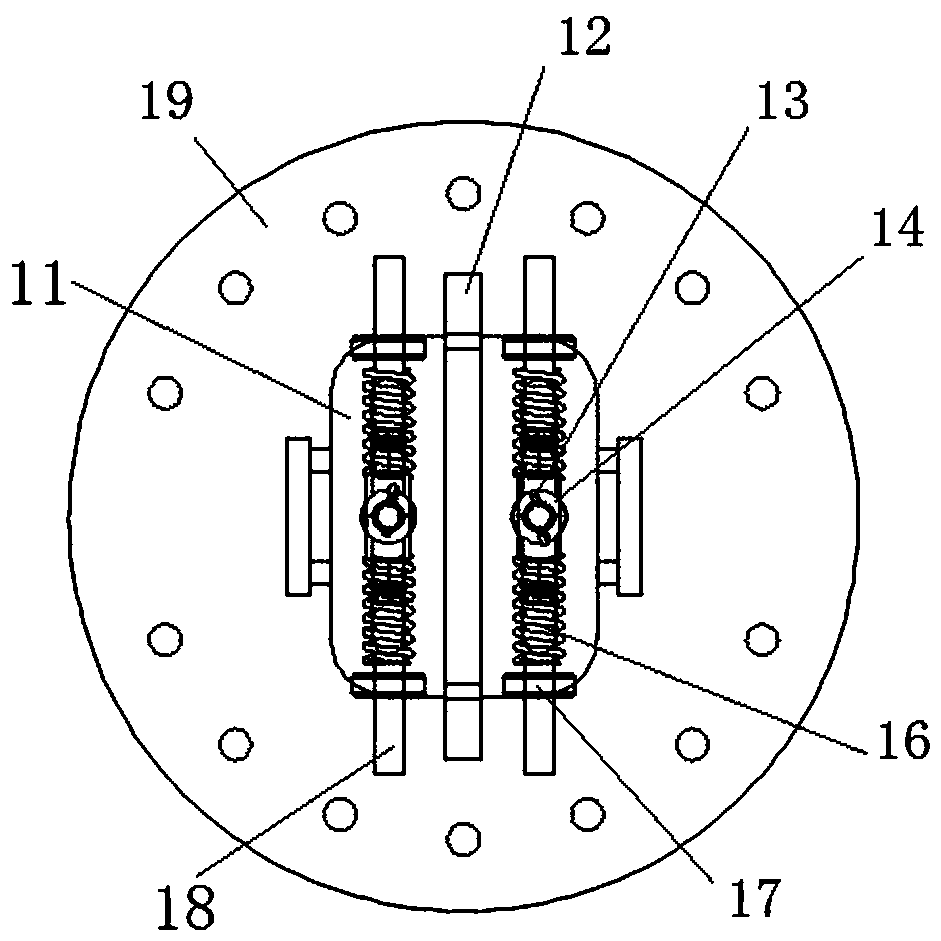

Examples

specific Embodiment 2

[0038] Specific embodiment two of the pipe bus bar supporting fittings of the present invention: as Figure 5 As shown, the difference from the first embodiment is that the pin shaft 14 is not provided with a spring guide rod, and the pin shaft 14 is slidably fitted in the sliding guide hole 20 .

specific Embodiment 3

[0039] Specific embodiment three of the pipe bus bar supporting fittings of the present invention: as Figure 6 As shown, the difference from the first embodiment is that the slider 15 and the pin shaft 14 are only provided on one side of the vertical plate 12, and the other end is fixedly connected.

[0040] Specific embodiment four of the pipe bus bar supporting fittings of the present invention: as Figure 7 As shown, the difference with the specific embodiment one is that the spring guide rod 18 is a through shaft, and the middle position of the through shaft is provided with a through hole, and the pin shaft 14 passes through the through hole and is limited in the through hole with the spring guide rod. 18, the self-returning spring 16 is sleeved on both sides of the spring guide rod 18 in the sliding direction of the pin shaft 14, and is limited by the pin shaft 14.

[0041] In other embodiments, the support frame is provided with a slideway, and the pipe busbar support...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com