Driving method of six-phase and three-phase double-winding suspension complementary non-bearing magnetic flux motor

A flux motor and drive method technology, applied in the direction of controlling generators, motor generators, electromechanical brakes, etc., can solve the problems of the restriction of ampere-turns of embedded coils, small slot space, etc., to improve reliable operation capabilities, The effect of improving the dynamic response performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments.

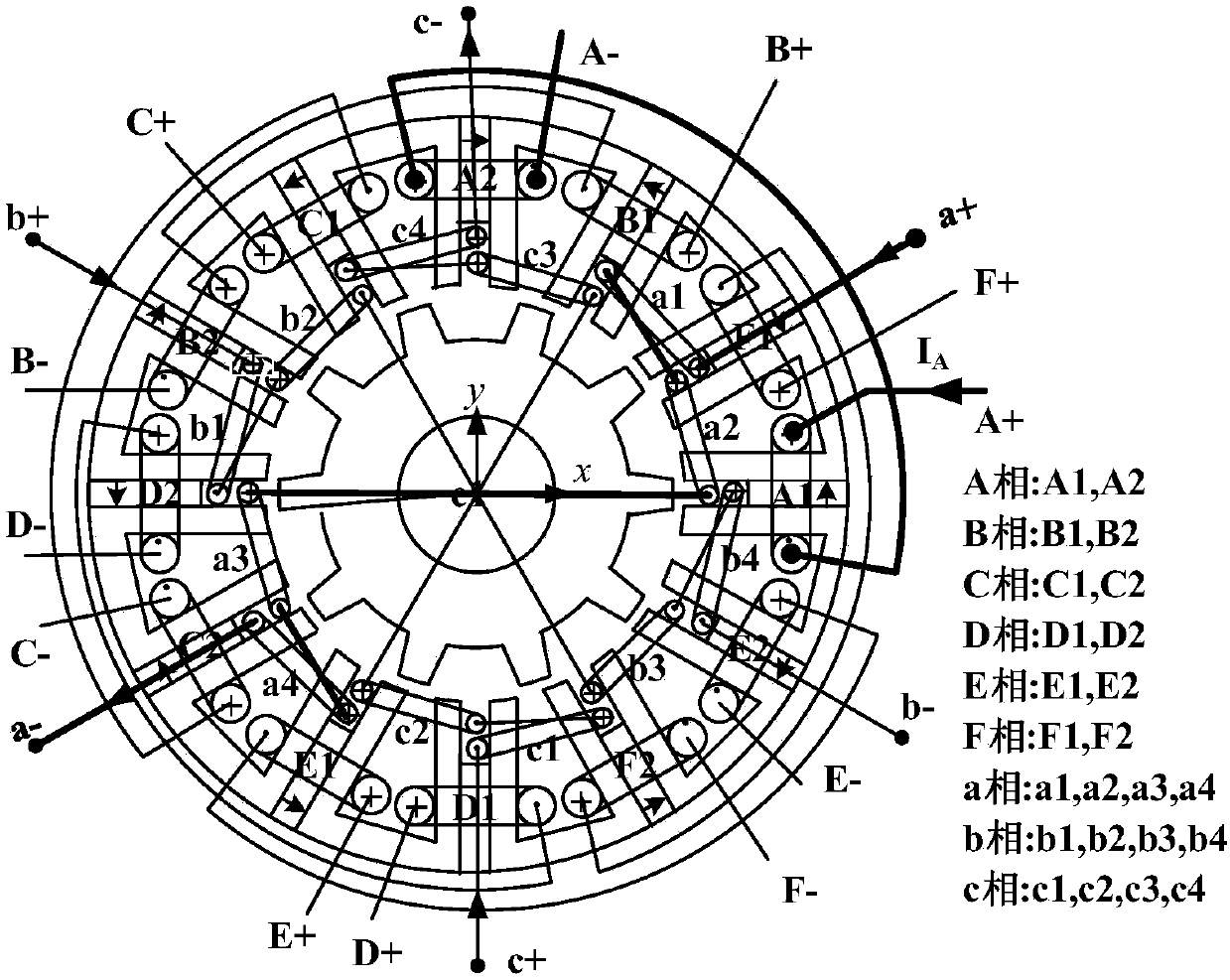

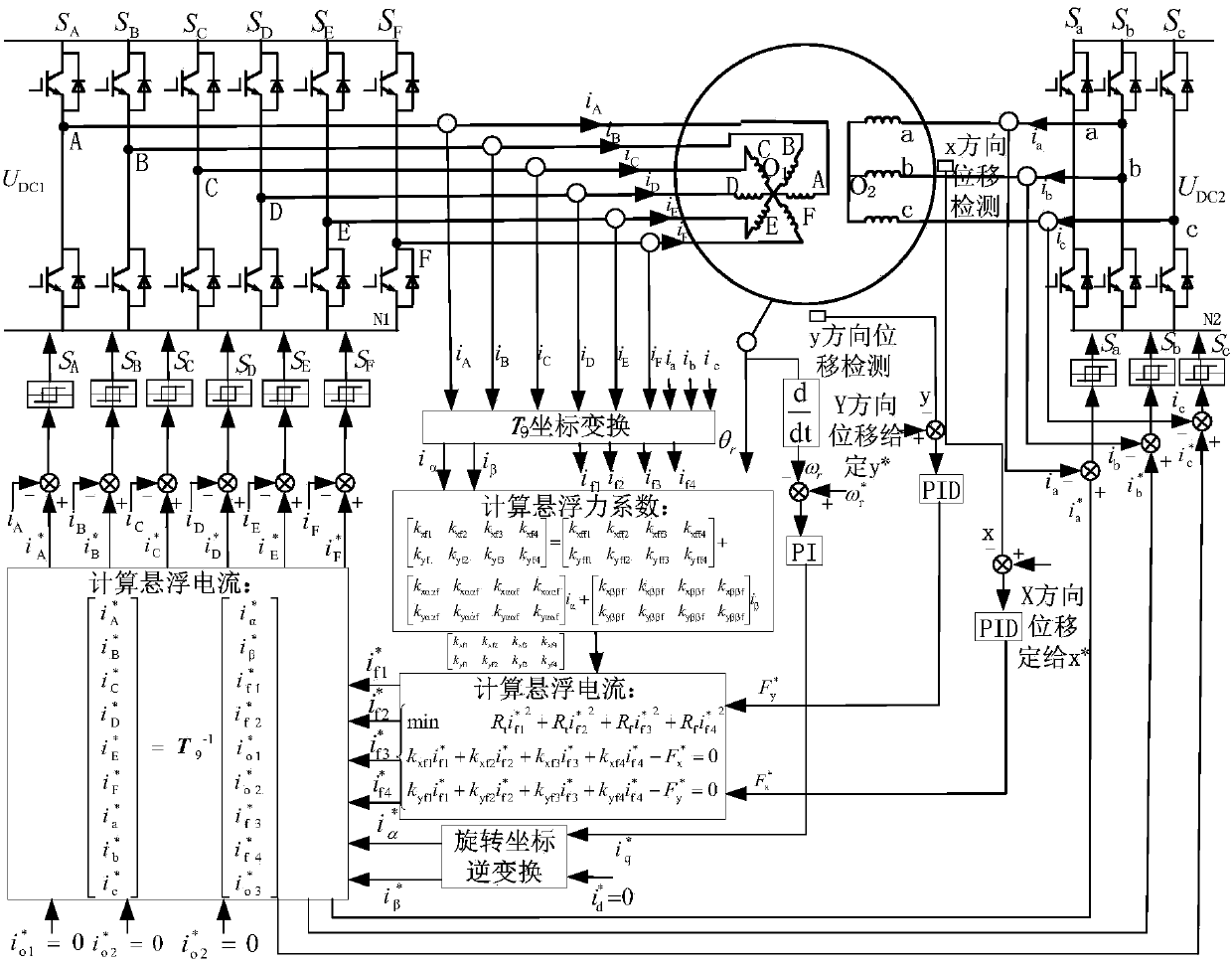

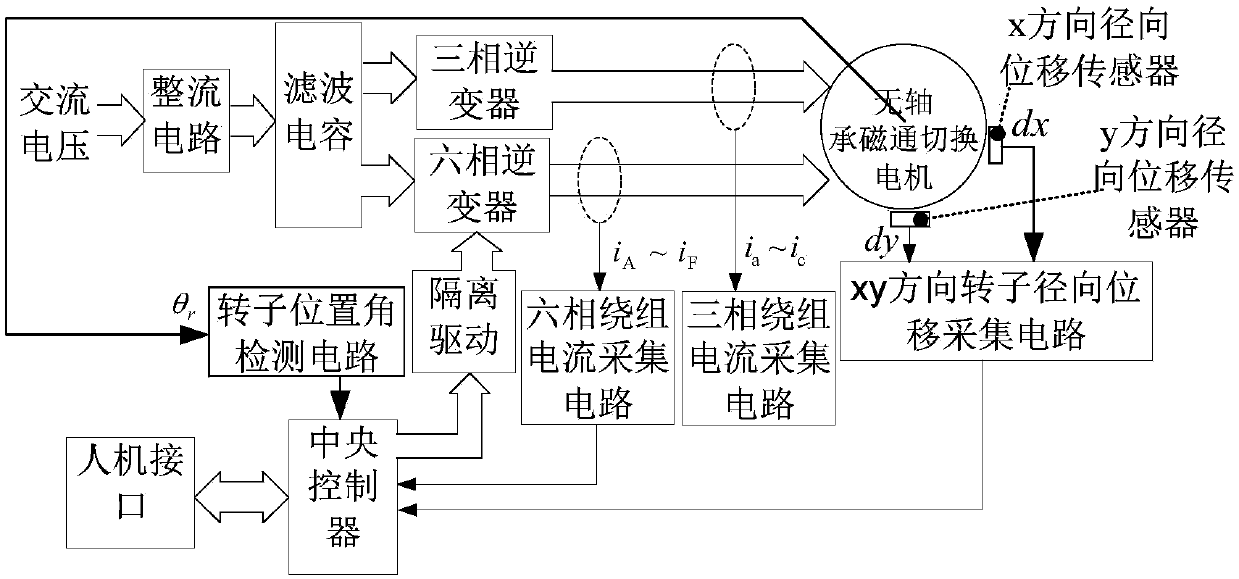

[0019] In order to avoid the deficiencies of the prior art, the present invention proposes a six-phase and three-phase double-winding suspension complementary type bearingless magnetic flux motor driving method. Two sets of windings are embedded in the stator of the motor at the same time: one set is a six-phase winding composed of coils nested on the stator poles, and the other set is the main suspension winding embedded in the permanent magnet slot to generate the main suspension force required by the rotor. The torque current and levitation current flow through the six-phase winding at the same time to generate the torque required by the load and the compensation levitation required by the rotor levitation. Under the condition of meeting the requirement of rotor suspension force, the copper loss generated by the six-phase suspension current ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com