A bearingless permanent magnet synchronous motor

A permanent magnet synchronous motor, bearingless technology, applied in electric components, electromechanical devices, electrical components, etc., can solve the problems that the center of the stator and rotor cannot overlap when the bearingless motor is running, which affects the stable floating performance of the rotor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

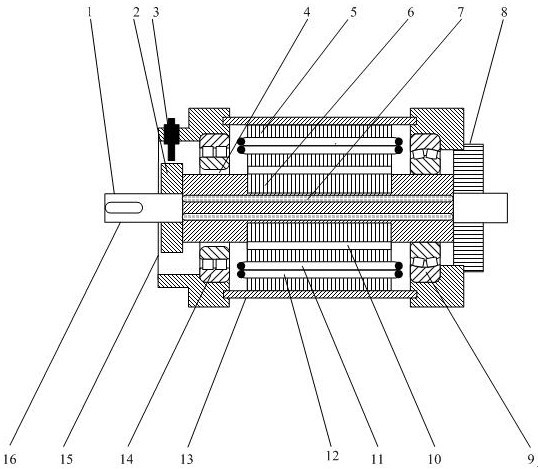

[0011] The present invention will be further described below in conjunction with accompanying drawing.

[0012] Such as figure 1 As shown, a bearingless permanent magnet synchronous motor, one end of the rotor shaft 1 is a suspension end 16, and an annular reference ring 2 is fixed on the rotor shaft 1 inside the motor end cover 15 of the suspension end, and the suspension end of the rotor shaft 1 is installed There are auxiliary rolling bearings 14 to prevent the rotor 6 from colliding with the stator 5 when no radial levitation force current is applied. There is a gap 4 between the auxiliary rolling bearing 14 and the rotor shaft 1. When the levitation winding 12 is supplied with current to generate a levitation force, the rotor shaft 1 is suspended from the auxiliary rolling bearing 14, and the auxiliary rolling bearing 14 stops. A position sensor 3 is installed on the motor end cover 15 on the side of the floating end 16 of the rotor shaft 1, which is radially aligned wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com