Speed sensorless control method for bearing-free asynchronous motor

A speed sensorless, asynchronous motor technology, applied in motor generator control, electronic commutation motor control, control system, etc., can solve problems such as increased cost investment, high-frequency signal doping, complex control system, etc., to ensure stability The effect of suspension, simplification of structure, and promotion of miniaturization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

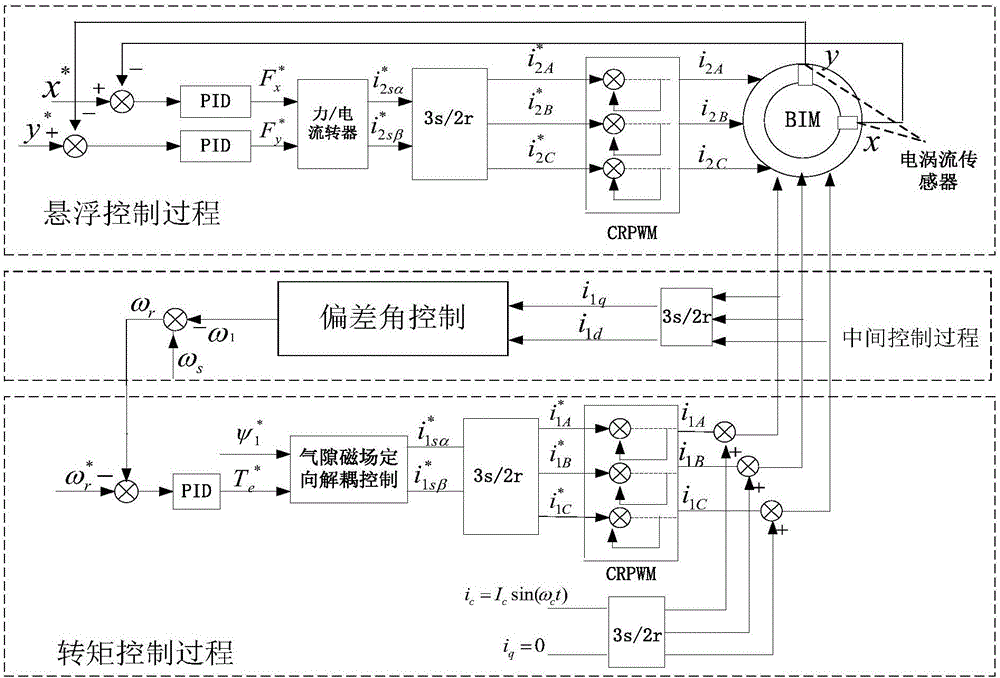

[0044] Such as figure 1 , a speed sensorless control method for a bearingless asynchronous motor, characterized in that it includes a suspension control process, an intermediate control process and a torque control process, wherein the suspension control process includes the following steps:

[0045] Step 1: Compare the radial displacement offset x, y of the bearingless asynchronous motor rotor measured by the eddy current sensor with the given radial displacement offset x of the rotor in the x, y direction * 、y * As the input of the comparator, its output value is adjusted by the PID controller to generate a given radial suspension force F of the rotor of the bearingless asynchronous motor in the x and y directions x * , F y * ;

[0046] Step 2: Set the given radia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com