Different-position double-cycloid rotor oil pump

A rotor oil pump and oil pump technology, which is applied to lubricating pumps, mechanical equipment, engine components, etc., can solve the problems of excessive volume of high-power oil suction chamber, wear of the oil pump, and low work efficiency, and achieve balanced force and extended Effects of service life and power consumption reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to make the purpose and technical solution of the present invention clearer, the technical solution of the present invention will be clearly and completely described below in conjunction with the embodiments of the present invention.

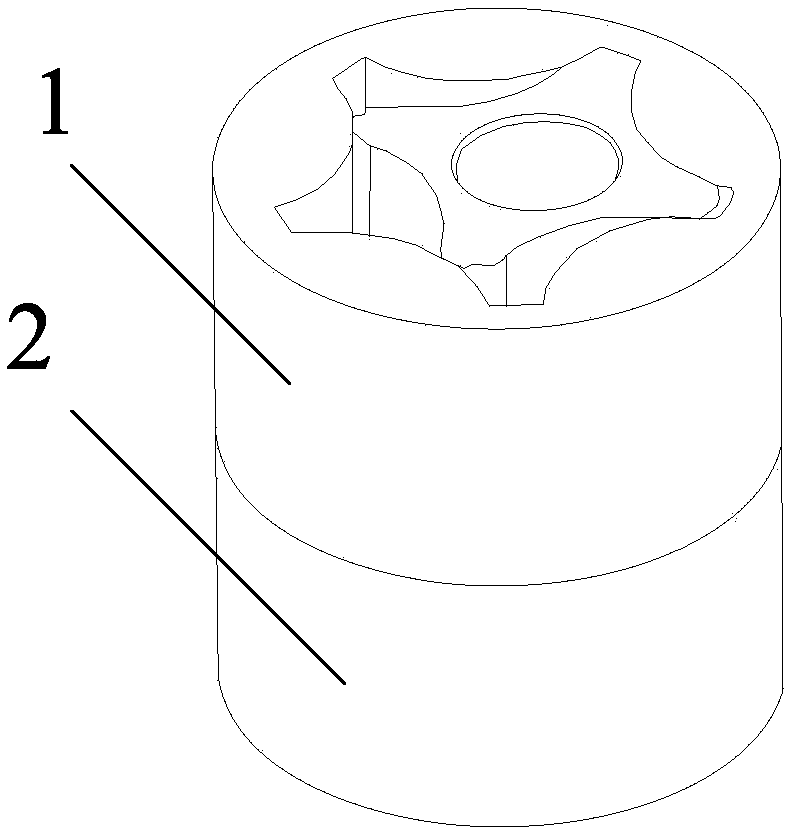

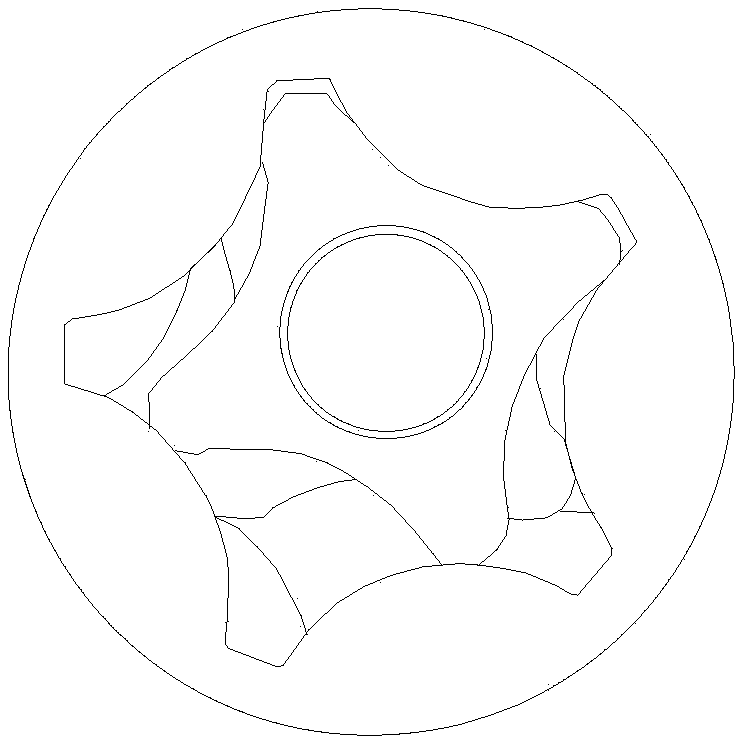

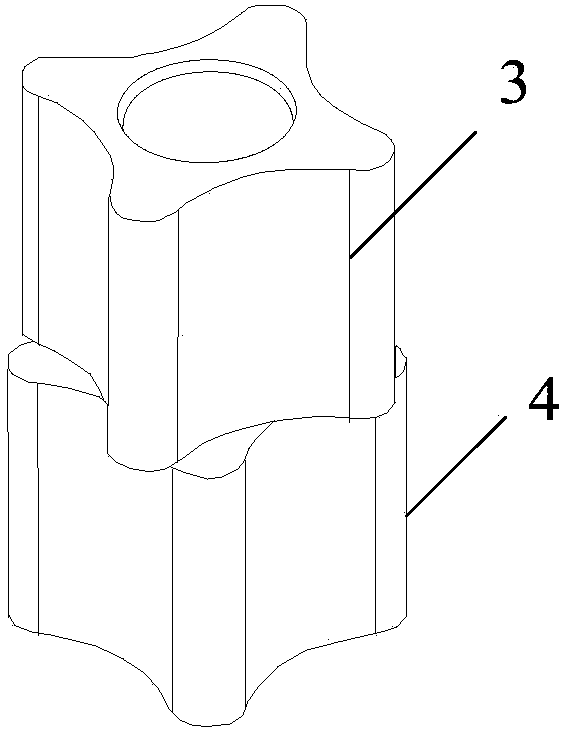

[0016] Such as Figure 1-4 As shown, an ectopic double cycloid rotor oil pump includes an oil pump body, a pump cover and a rotor. The rotor includes an inner rotor and an outer rotor. The number of concave teeth of the outer rotor is one more than the convex teeth of the inner rotor. The outer rotor includes a first outer rotor 1 and a second outer rotor 2 that are stacked up and down. The first outer rotor 1 and the second outer rotor 2 have the same structure, and both have five concave teeth; the first outer rotor 1 The included angle projected on the same horizontal plane with the corresponding concave teeth of the second outer rotor 2 is 22.5 degrees; The structure of the rotor 4 is the same, and they all have four convex ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com