Tubular heater

A tube heater and heating tube technology, applied in the direction of heat exchanger types, heat exchanger shells, indirect heat exchangers, etc., can solve the problems of difficulty in meeting customers, high water production costs, and unrecoverable condensate water.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with accompanying drawing.

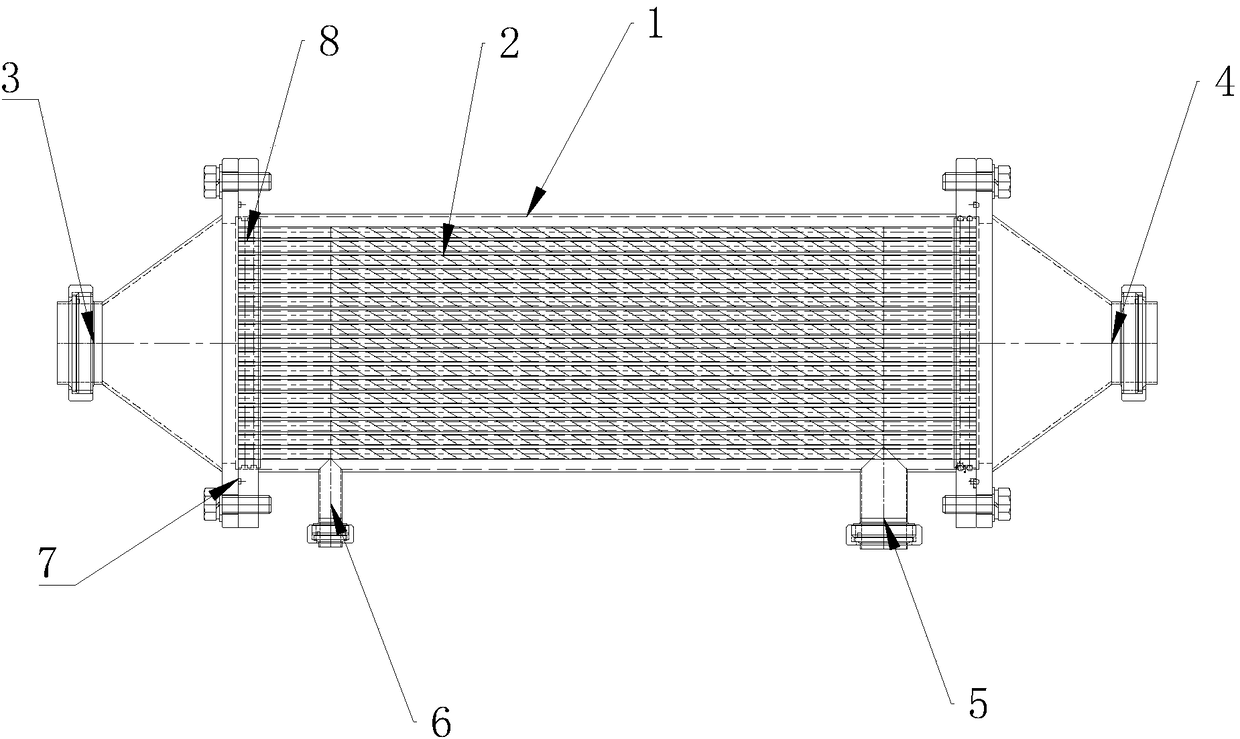

[0012] Such as figure 1 As shown, a tubular heater includes a casing 1, and a plurality of heating tubes 2 for circulating water are arranged in the casing 1, and the two sides of the casing 1 are respectively provided with the plurality of heating tubes. 2 communicated with the cold water inlet 3 and the hot water outlet 4, the housing 1 is provided with a steam inlet 5 near the hot water outlet 4, and the housing 1 is provided with a condensed water outlet 6 near the cold water inlet 3.

[0013] The object of the present invention is to provide a tubular heater with the function of heating cold water into hot water by using the principle of heat exchange between steam and water. Specifically, steam and water are used to make two independent systems, and the heat energy of the metal surface is transferred from the high position to the low position to heat the circulating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com