Self-priming packing decontamination device

A self-priming and decontamination technology, which is applied in chemical/physical/physicochemical fixed reactors, separation methods, and separation of dispersed particles, can solve the problems of low decontamination efficiency, insufficient decontamination of gas-liquid hazardous chemicals, Inconvenient decontamination operation and other problems, to achieve the effect of convenient decontamination operation, sufficient absorption and high absorption efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

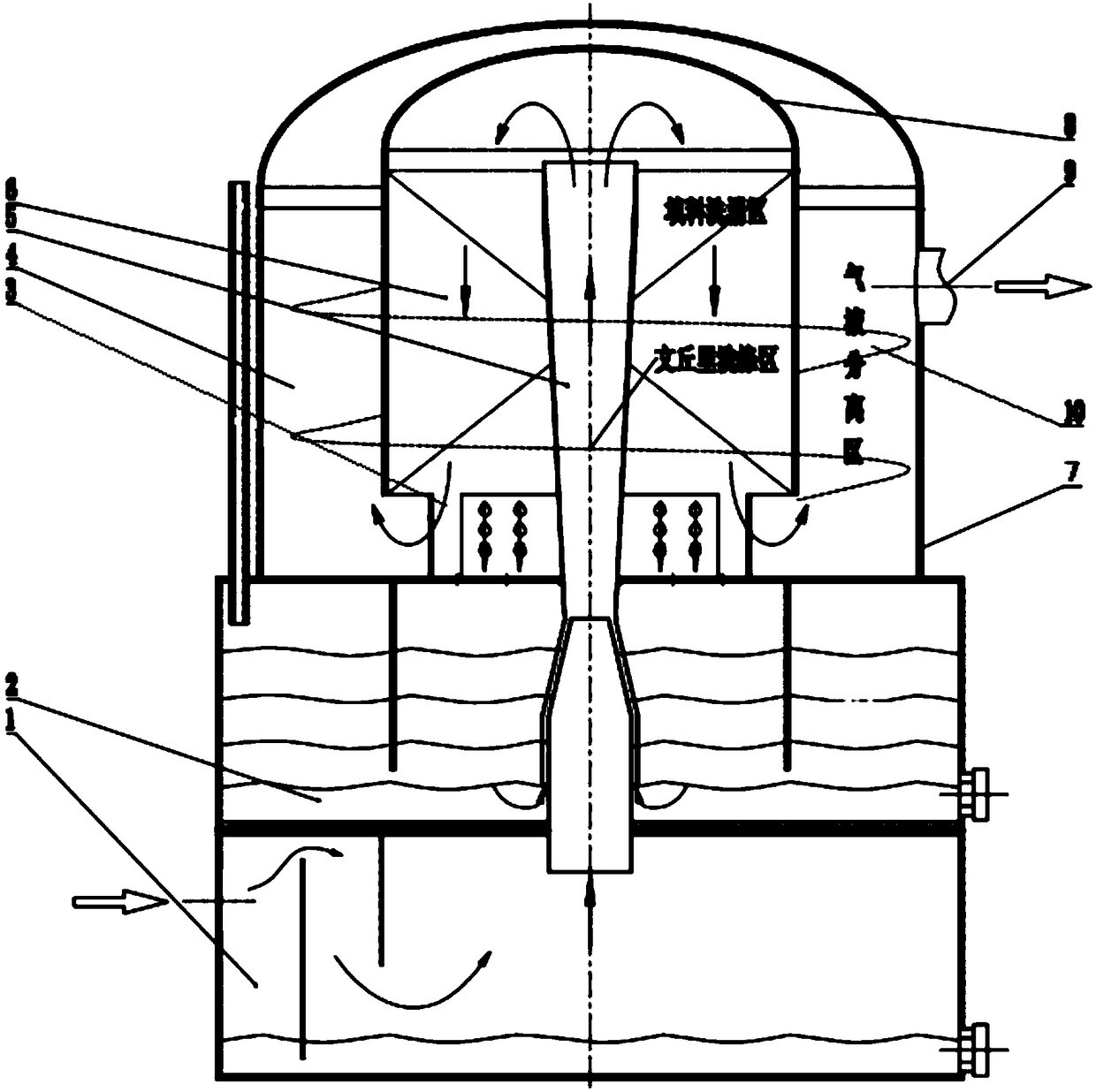

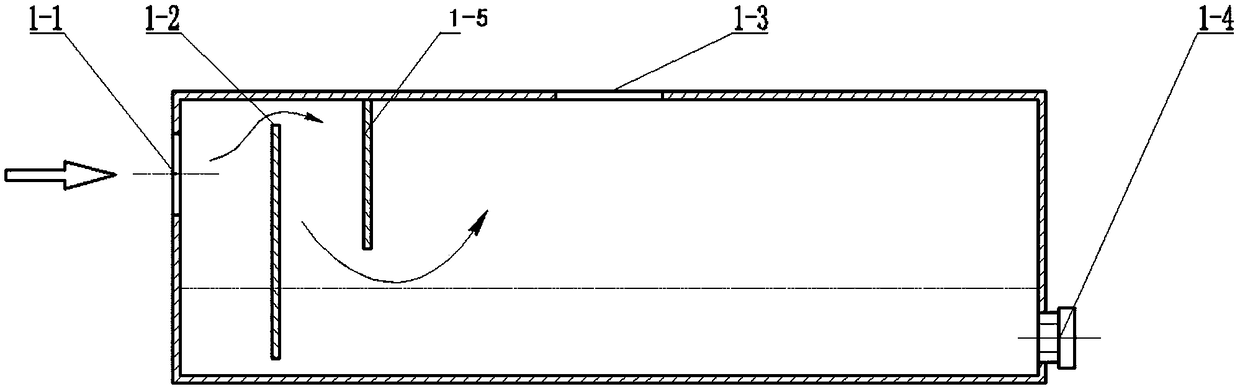

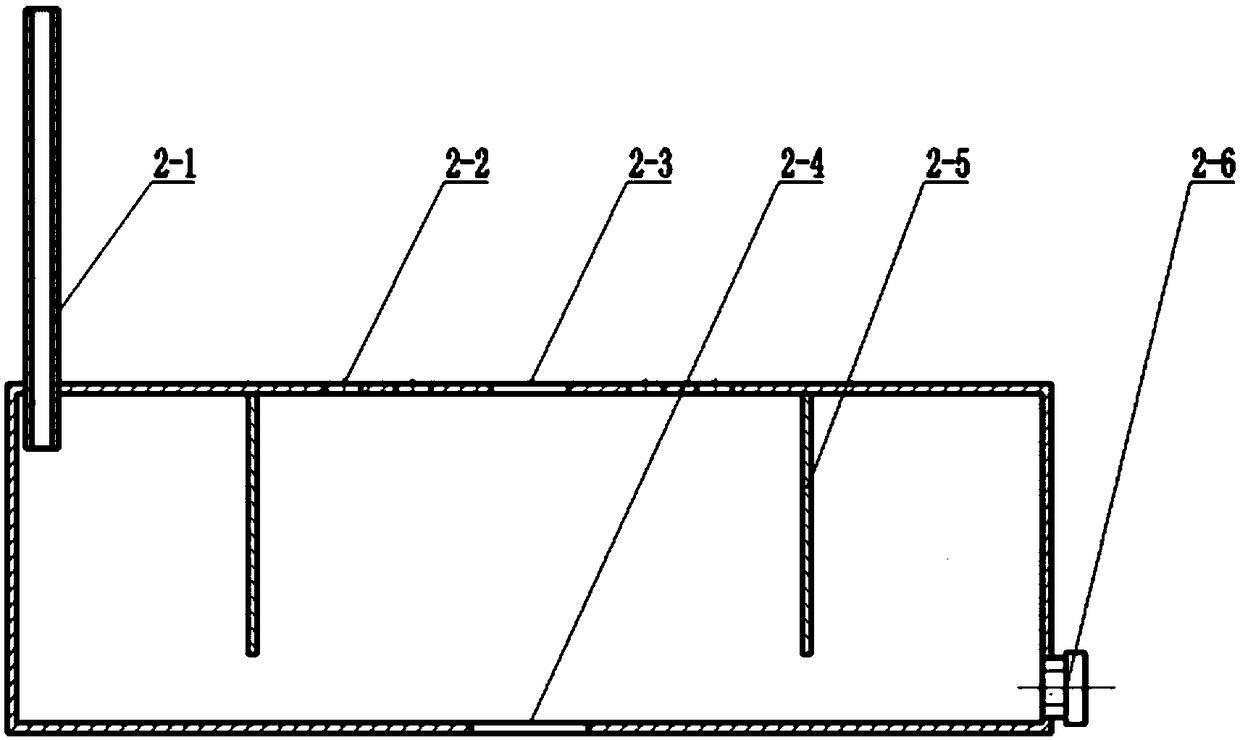

[0024] Such as Figure 1 to Figure 4 As shown, this embodiment provides a self-priming packing decontamination device, one side of the side wall of the waste liquid collection bin 1 is provided with an air inlet 1-1, and the air inlet 1-1 is connected with a For the pipeline of chemicals, the side wall of the waste liquid collection bin 1 opposite to the air inlet 1-1 is provided with a first liquid discharge port 1-4. One side of the waste liquid collection bin 1 is provided with a front baffle 1-2 and a rear baffle 1-5 facing the air inlet 1-1, and the upper part of the front baffle 1-2 is connected to the waste liquid collection bin 1. An air passage is left between the upper inner walls of the front baffle plate 1-2, and the bottom of the front baffle plate 1-2 is submerged in the liquid in the waste liquid collection bin 1, and the rear baffle plate 1-5 is suspended and connected to the upper inner wall of the waste liquid collection bin 1. The upper part of the waste li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com