An improvement method of coal mill impeller device based on cfd technology

A coal mill and impeller technology, applied in geometric CAD, computer-aided design, instruments, etc., can solve the problems of impeller device structural improvement, high cost, and large structural improvement, and achieve the effect of small structural changes and easy implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

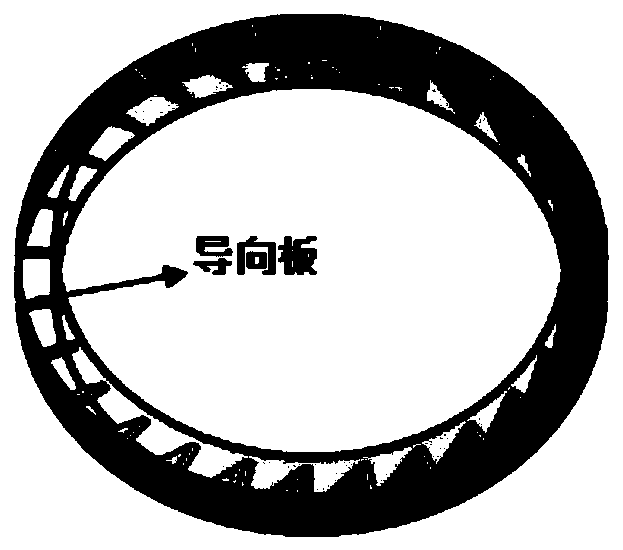

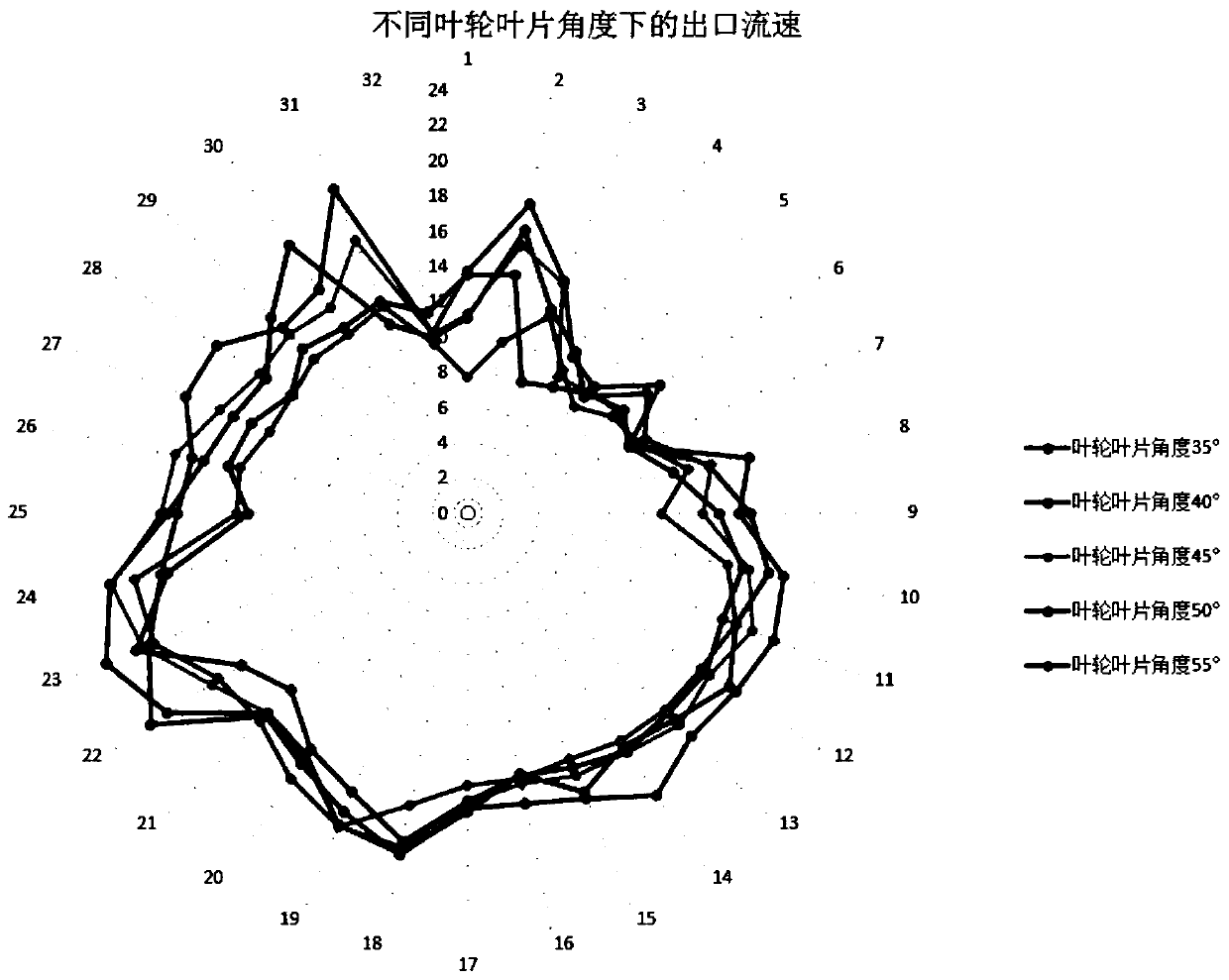

[0022] The present invention adopts the CFD (computational fluid dynamics) technology, analyzes the flow distribution of the impeller device inlet and outlet area in principle, and calculates the installation angle of the guide plate in the impeller device, the number of wing plates and the width change on the basis of the actual inlet wind speed. The influence law of outlet average velocity, local minimum velocity and pressure drop, combined with the actual manufacturing and installation process, obtained the impeller device with improved structure.

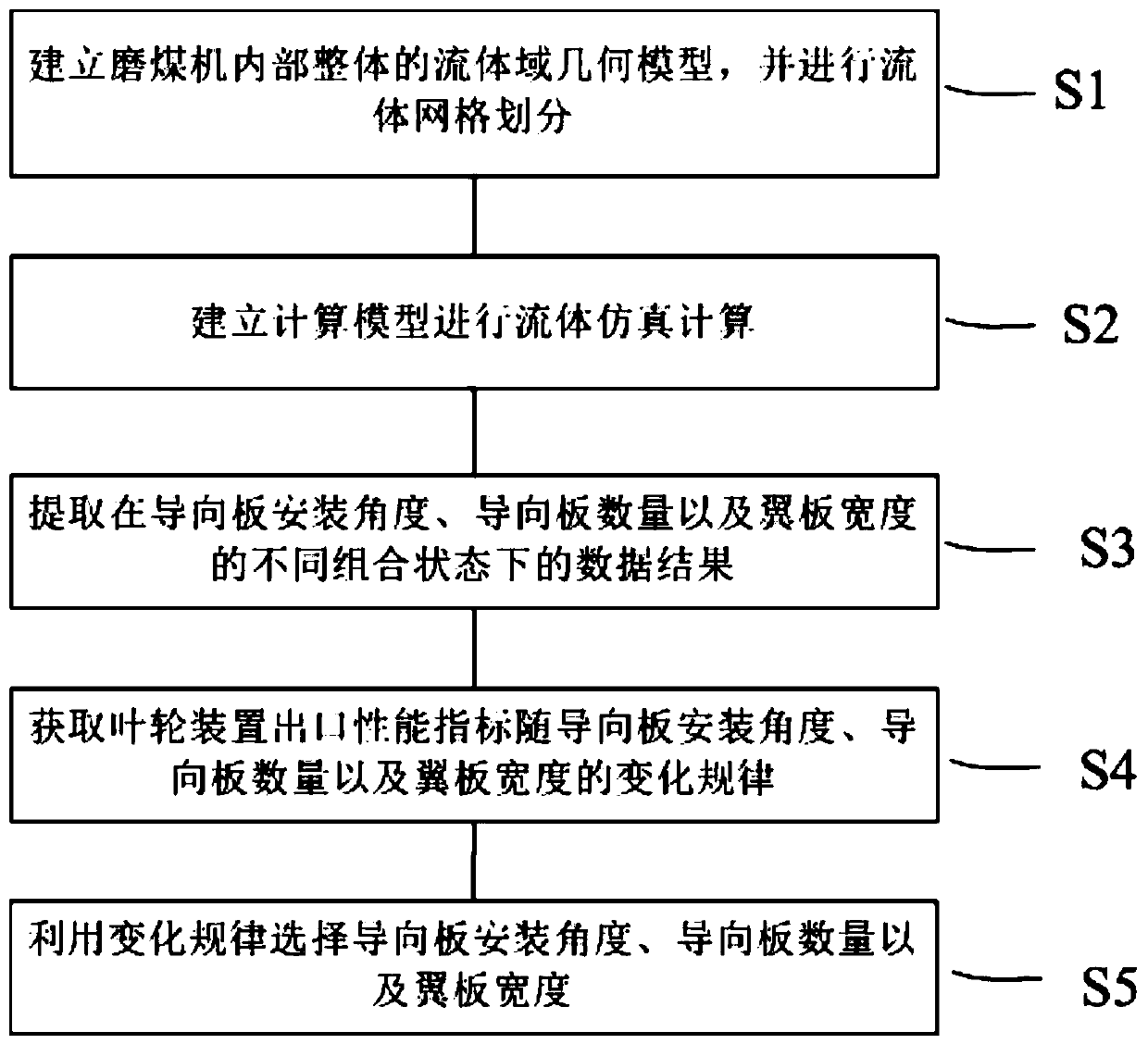

[0023] specifically, figure 1 It is a flowchart of a method for improving a coal mill impeller device based on CFD technology according to a preferred embodiment of the present invention.

[0024] Such as figure 1 As shown, the method for improving the impeller device of a coal mill based on CFD technology according to a preferred embodiment of the present invention includes:

[0025] The first step S1: establish the overall f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com