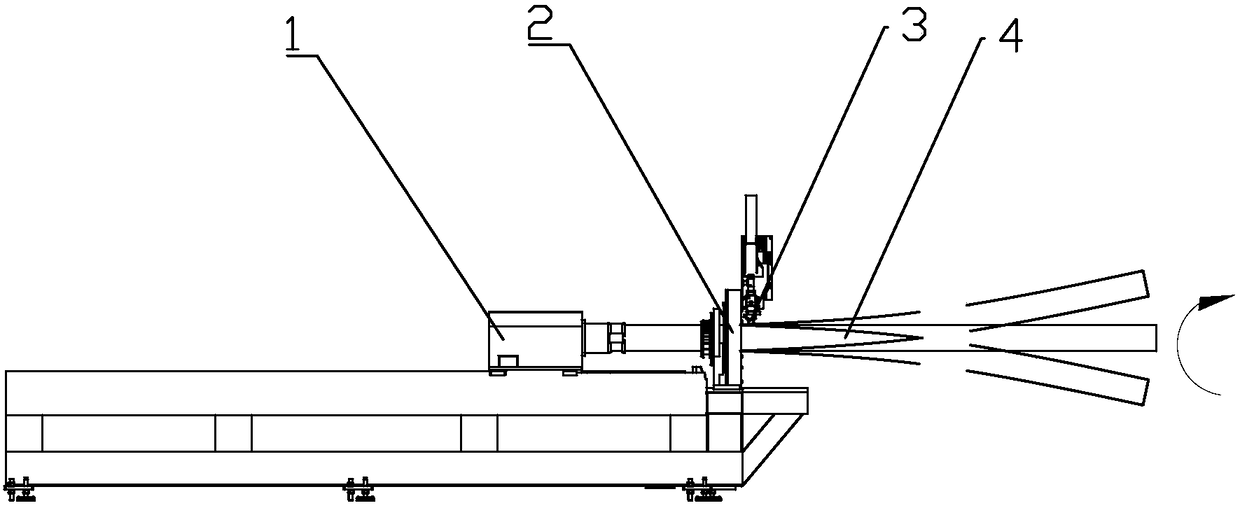

Servo supporting and blanking device used for laser pipe cutting machine

A technology of blanking device and pipe cutting machine, applied in auxiliary devices, laser welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems affecting cutting accuracy, swing, etc. The effect of swing amplitude

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

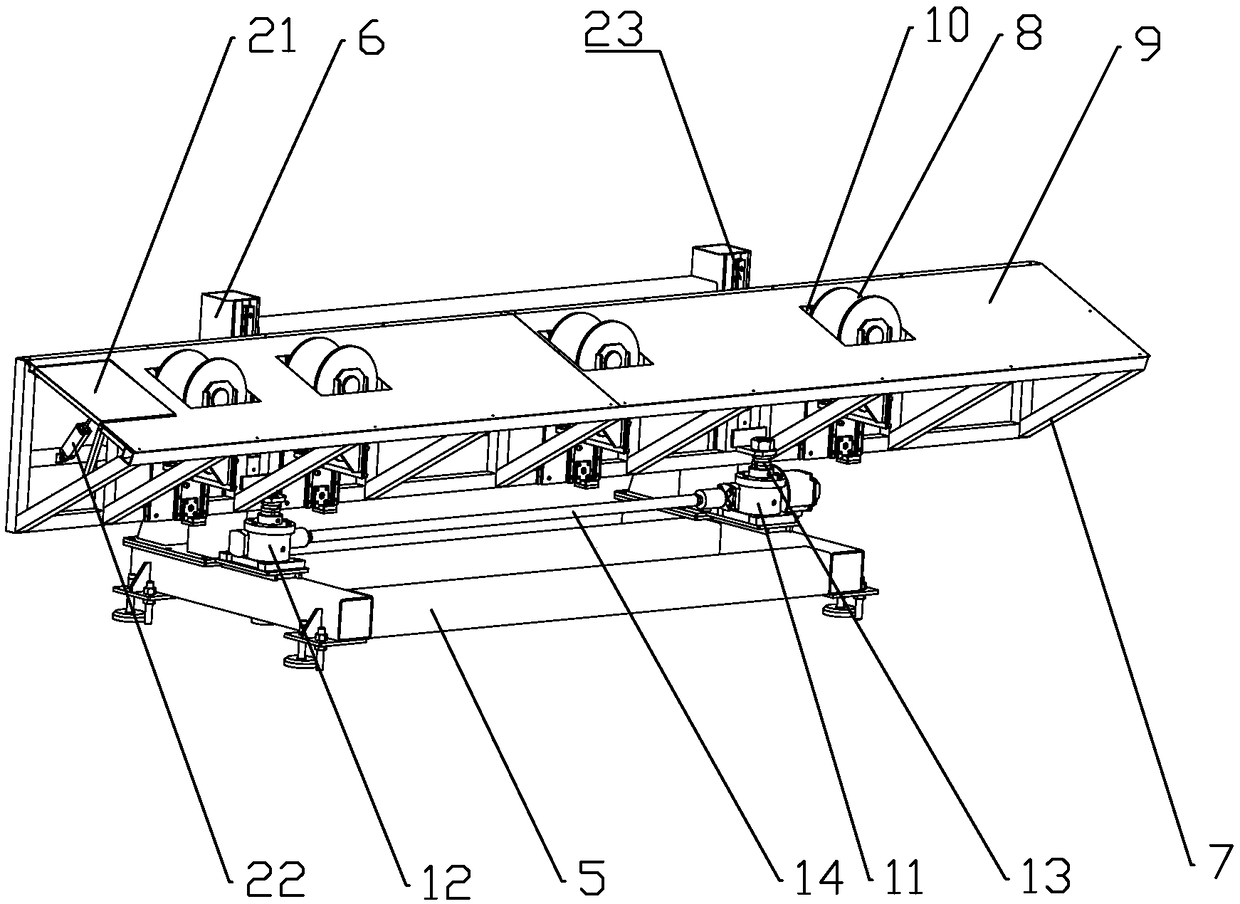

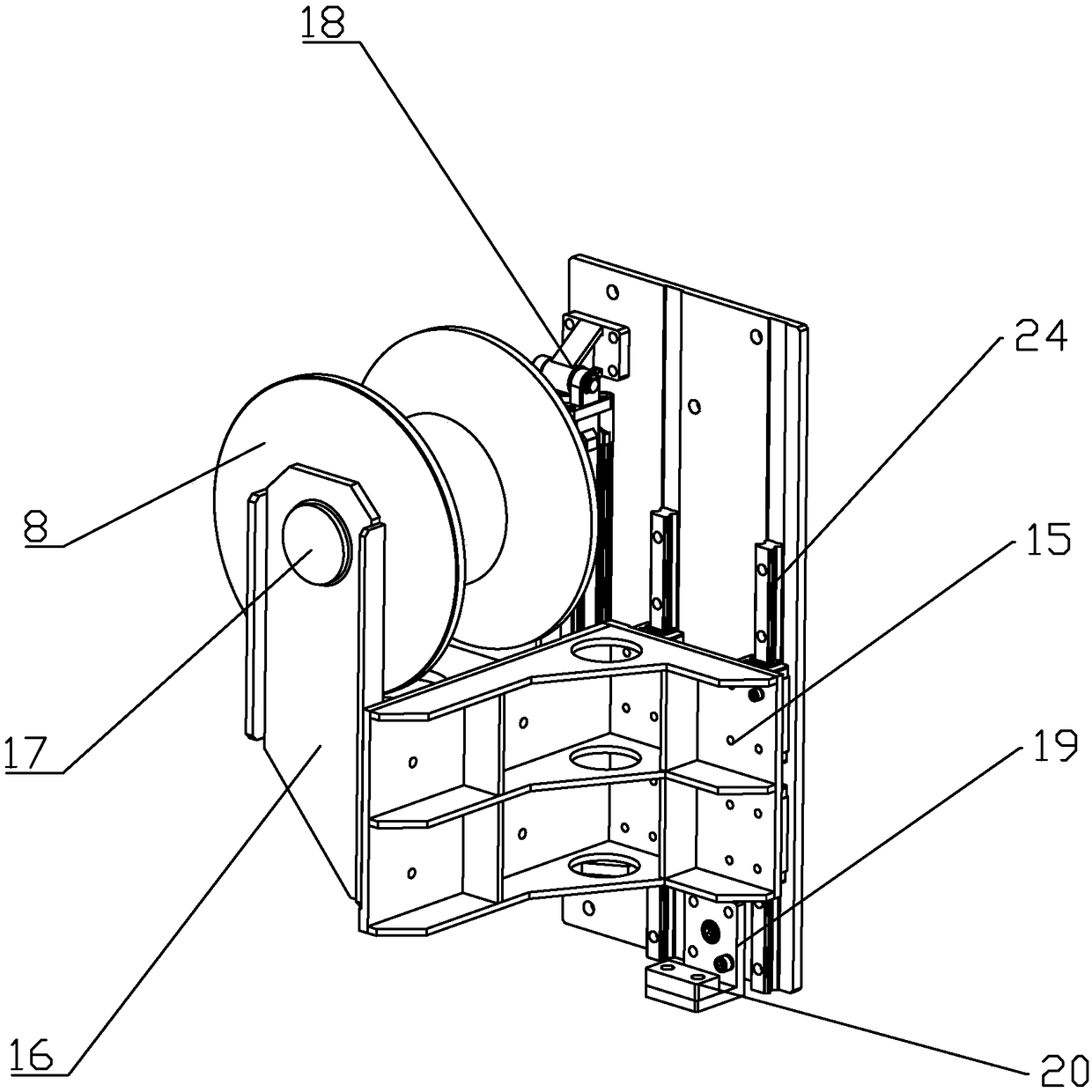

[0021] In order to clearly illustrate the technical features of this solution, the present invention will be described in detail below through specific implementation modes and in conjunction with the accompanying drawings.

[0022] like Figure 2-4 As shown, a follower supporting and blanking device for a laser pipe cutting machine includes an underframe 5, a fixed bracket 6 is vertically provided on the underframe 5, and a blanking rack 7 is movable on the fixed bracket 6 , the blanking frame 7 is connected with the follow-up drive device located on the bottom frame 5, and several lifting rollers 8 components are arranged at intervals on the blanking frame 7 along the length direction of the blanking frame 7, and each lifting roller 8 components The position of the idler roller 8 is aligned.

[0023] The follow-up driving device includes a motor, and the rotation speed of the motor corresponds to the rotation speed of the steel pipe 4 to be processed driven by the chuck; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com