Screw driver

A screwdriver and screw technology, which is applied to screwdrivers, manufacturing tools, wrenches, etc., can solve problems such as screws falling into the cable trench outlet, hidden dangers of mechanical equipment operation, and the interior of mechanical equipment, so as to improve convenience, save operation time, good performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0034] The invention discloses a screwdriver, which is a hardware tool. The screwdriver has the function of preventing the screw from dropping after improving the existing screwdriver.

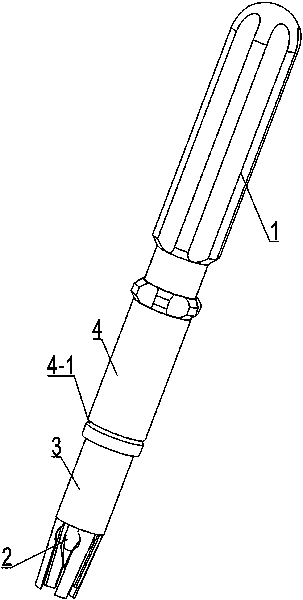

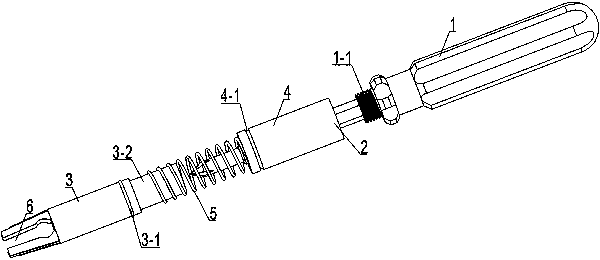

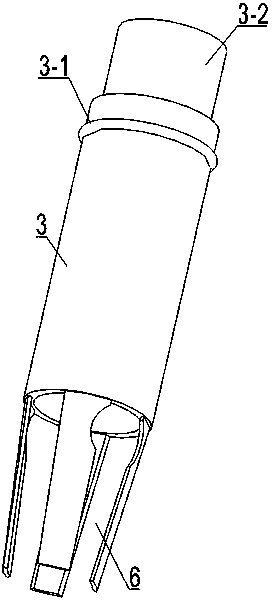

[0035] Screwdriver of the present invention, as figure 1 , figure 2 , image 3 As shown, it is an improved design of a screwdriver with a handle part 1 and a cutter body part 2, and a sleeve assembly with a cutter head sleeve 3 and a sliding sleeve 4 is arranged on the cutter body part 2 of the screwdriver. Wherein, the sliding sleeve 4 is fixedly connected to the lower end of the handle portion 1 at the top, and the cutter head sleeve 3 is sleeved under the sliding sleeve 4 . The sliding sleeve 4 is used to drive the screwdriver to move back and forth to install and disassemble the screw, and the lower end of the bit sleeve 3 can clamp and support the screw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com