Integrated robot joint device

An integrated technology of robot joints, applied in the direction of manipulators, manufacturing tools, joints, etc., can solve the problems of low load capacity, large size space, and short service life of harmonic reducers, so as to ensure high-quality stable operation and safe development Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings and examples.

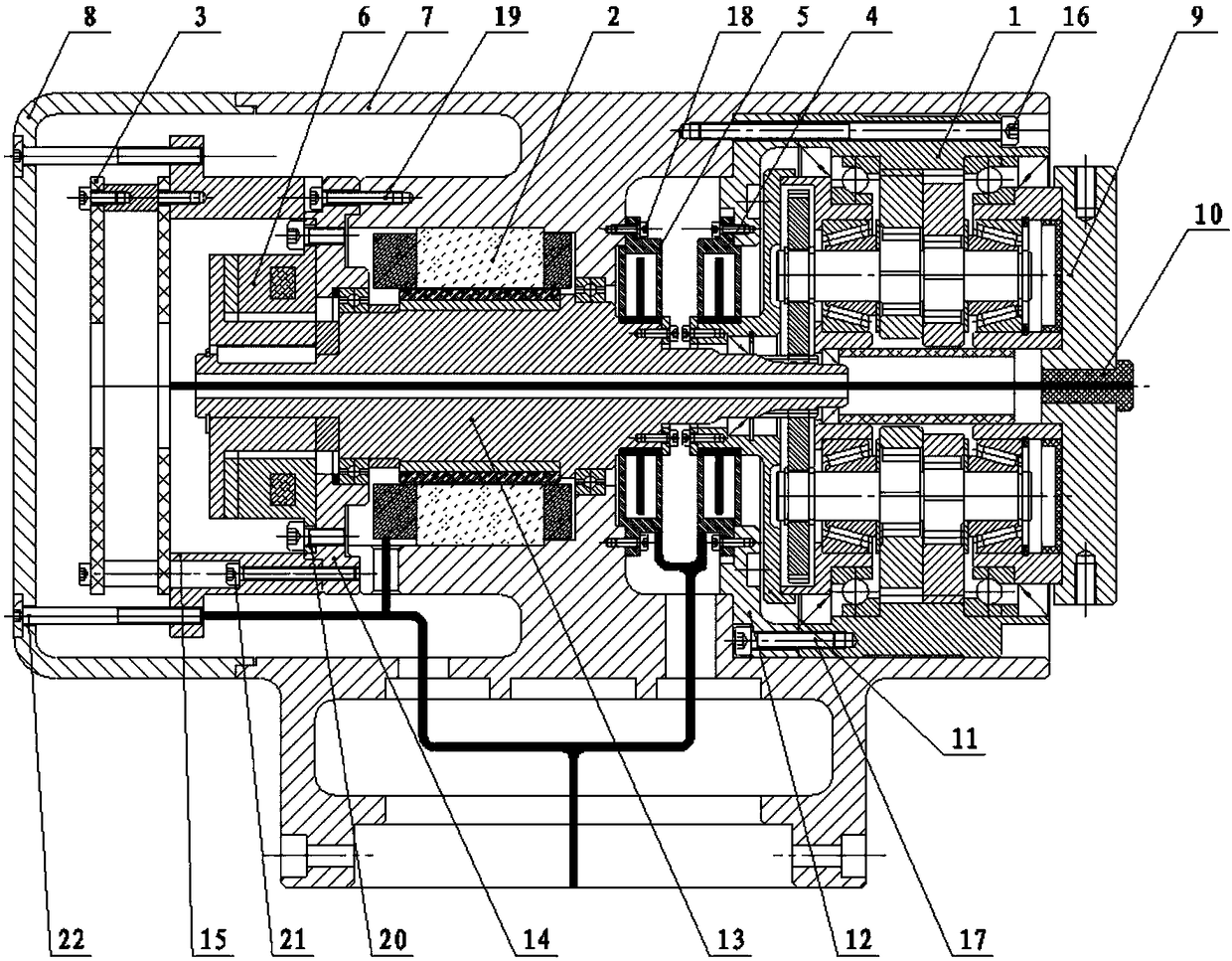

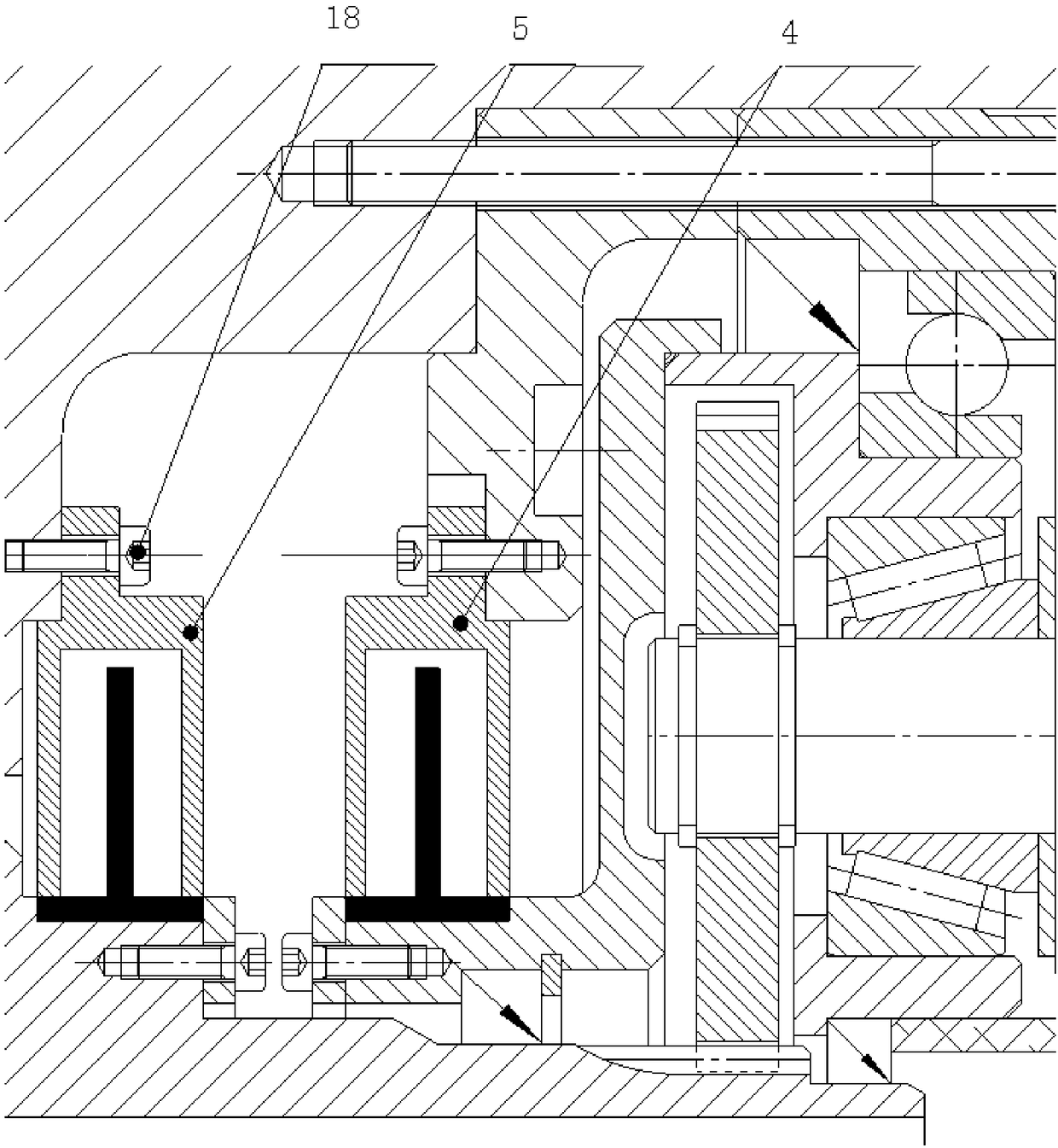

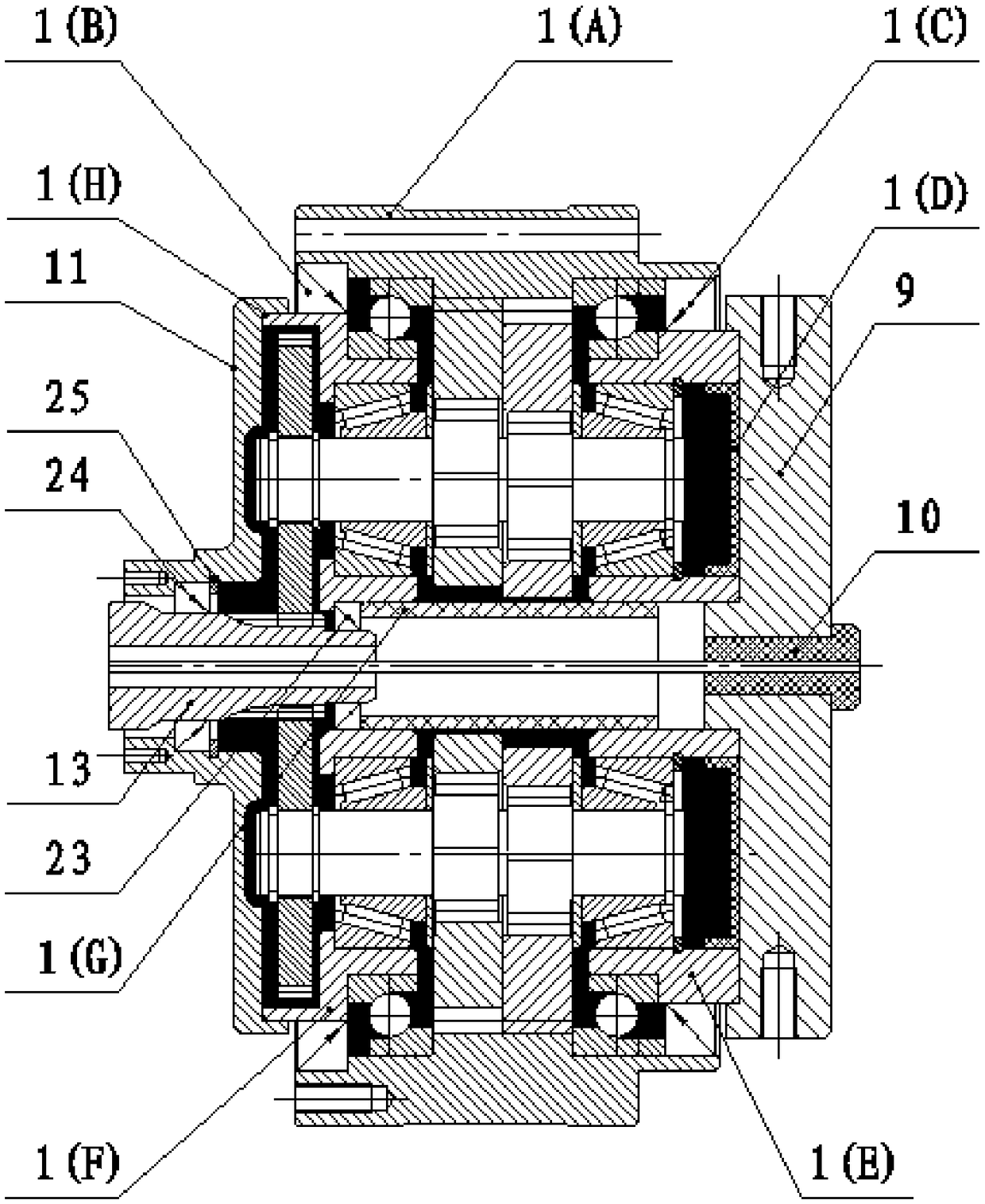

[0022] Such as figure 1 , 2 As shown, an integrated robot joint device includes RV reducer 1, frameless direct drive torque motor 2, DC drive 3, power-off brake 6, incremental encoder 5, single-turn absolute encoder 4, T Type shell 7;

[0023] The motor output shaft 13 is also used as the input shaft of the RV reducer; firstly, the motor incremental encoder 5 stator is fixedly connected to the inner end surface of the T-shaped housing 7 through the sensor connecting screw 18, and the rotor is installed on the motor output shaft 13, Thereafter, the stator of the frameless direct drive torque motor 2 is interference-fitted into the T-shaped housing 7 motor mounting seat, and its rotor is mounted on the motor output shaft 13 (specifically, it can be glued together), and then Install the motor output shaft 13 assembly on the T-shaped housing 7 through sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com