Sign blank processing equipment

A technology for processing equipment and blanks, which is applied to the field of non-marking rubber conveyor belts and manufacturing methods and processing equipment for marking blanks, can solve the problems of weak repair position, deformation of conveyor structure, economic losses of users, etc., so as to avoid accidents, The effect of ensuring quality and eliminating potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0073] Example: see Figure 1 to Figure 14 .

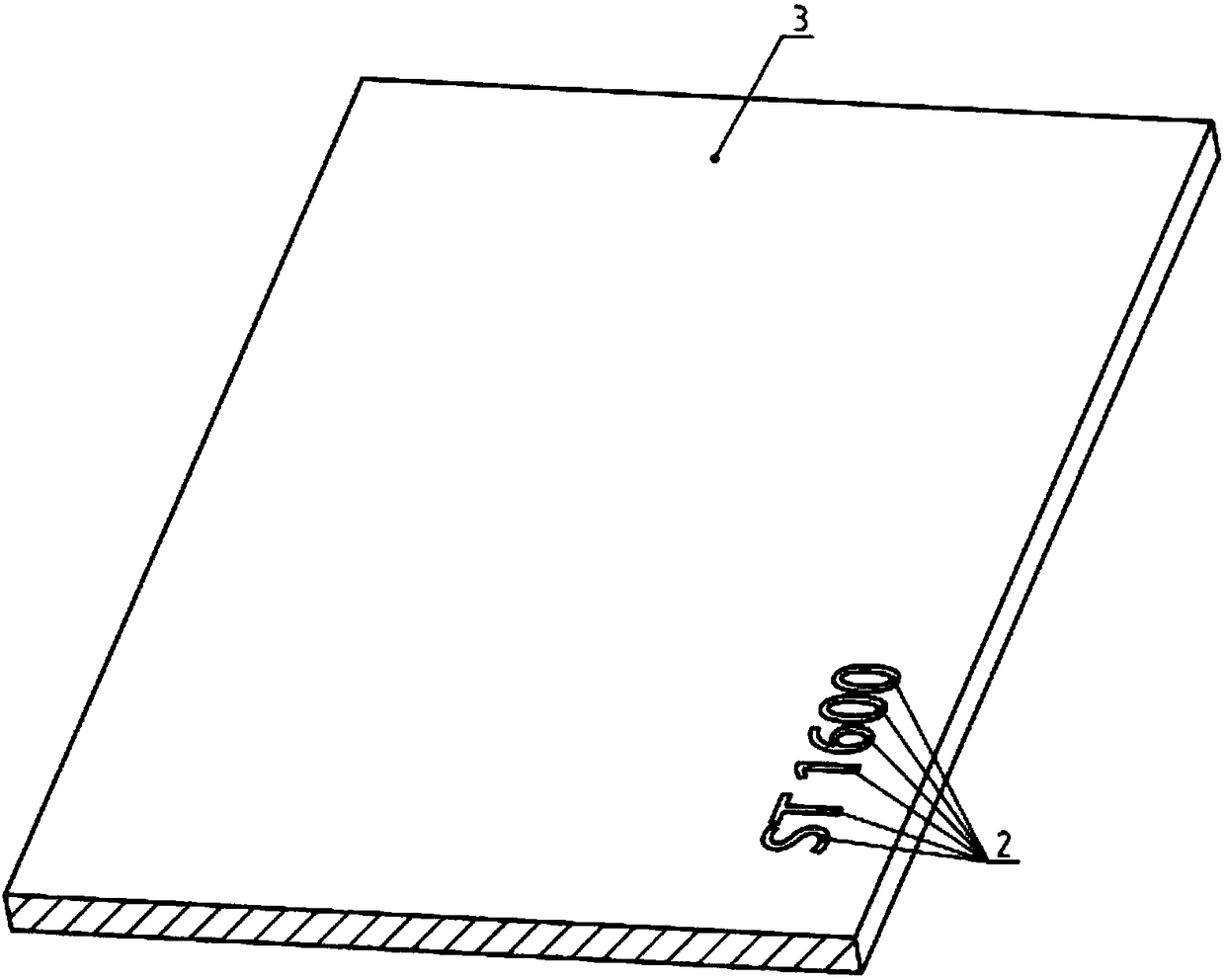

[0074] A non-marking rubber conveyor belt, including a base belt 3, the base belt 3 is a black ordinary rubber conveyor belt, characterized in that the base belt 3 has a logo symbol 2, which is "ST1600" composed of six characters, and the area where the logo symbol 2 is located It is a rubber compound containing a coloring agent. 100 parts by weight of the rubber compound contains 3 parts of titanium dioxide, and the symbol 2 is displayed as white.

[0075] According to the non-trace marking rubber conveyor belt described above, this embodiment also provides a manufacturing method of the non-trace marking rubber conveyor belt, including the following steps:

[0076] 1) Evenly mix titanium dioxide into the rubber compound, and roll it into a 4 mm thick white rubber film;

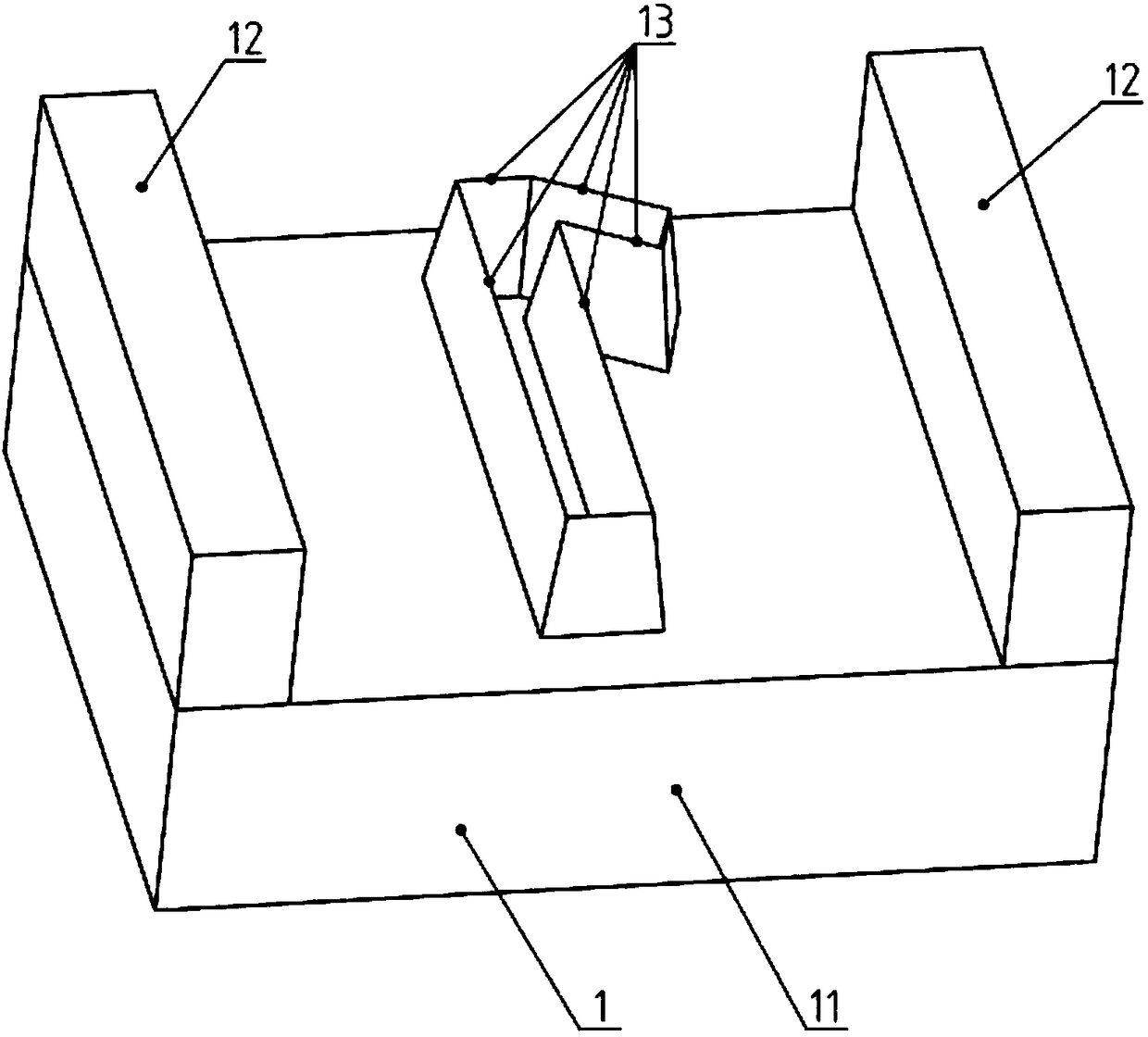

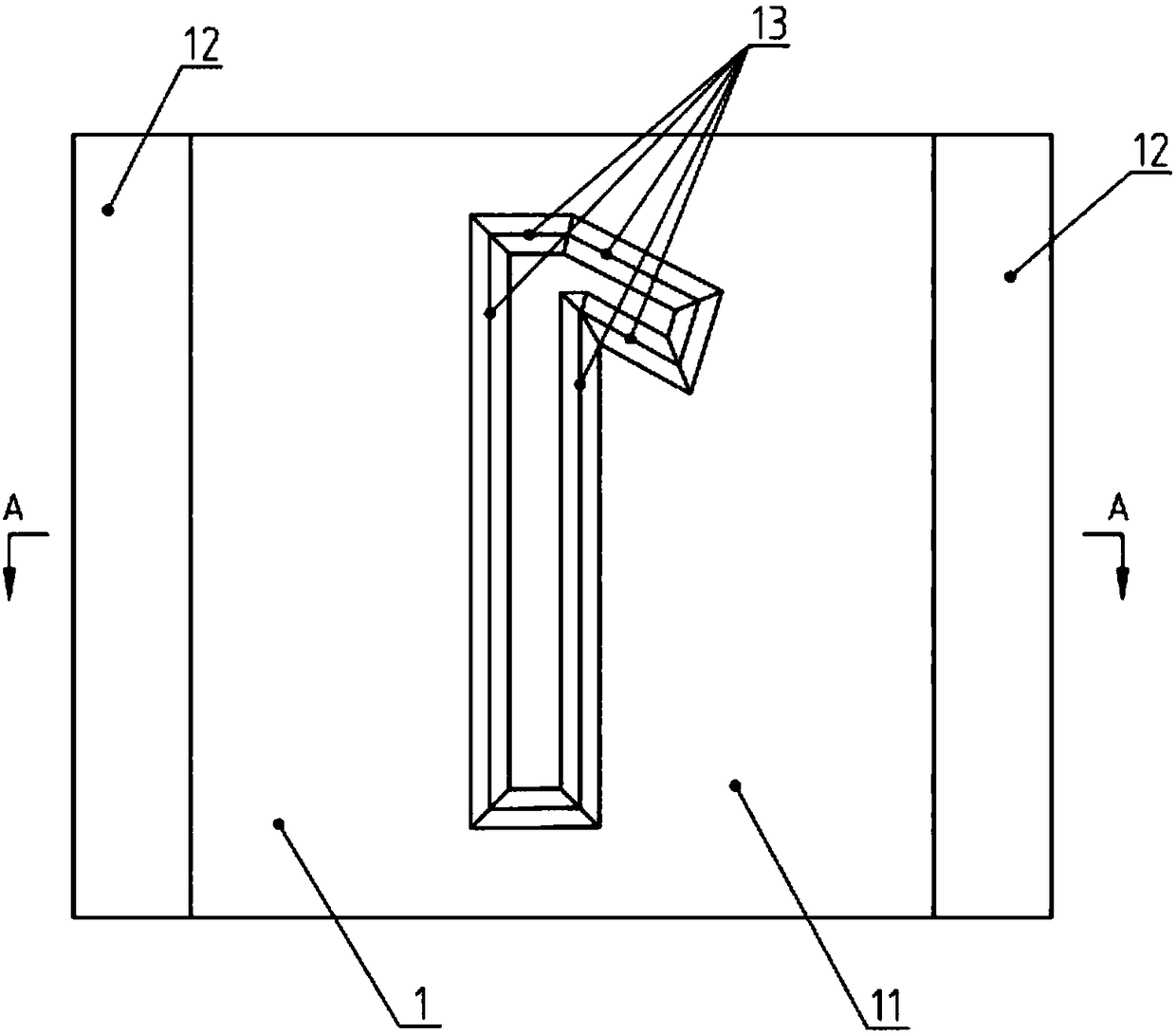

[0077] 2) Die-cut the sign blank on the rolled rubber film. The sign blank that needs to be punched in this embodiment has a letter "S", a letter "T", a number...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com