Adjustable shell component and part lifting appliance

A component and adjustable technology, applied in the direction of load hoisting components, transportation and packaging, can solve the problems of unstable component hoisting, design and manufacturing errors, and safety hazards, and improve production efficiency and practicability. Strong, avoid the effect of frequent replacement of spreaders

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

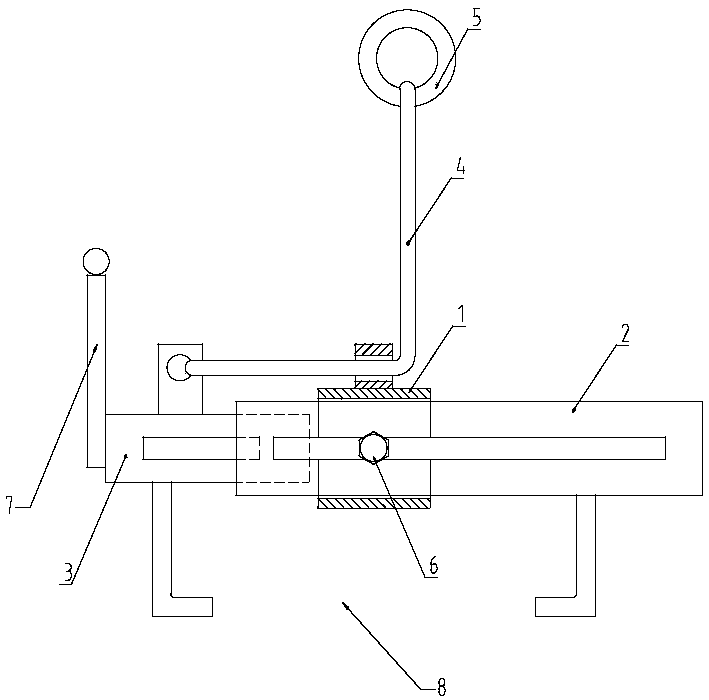

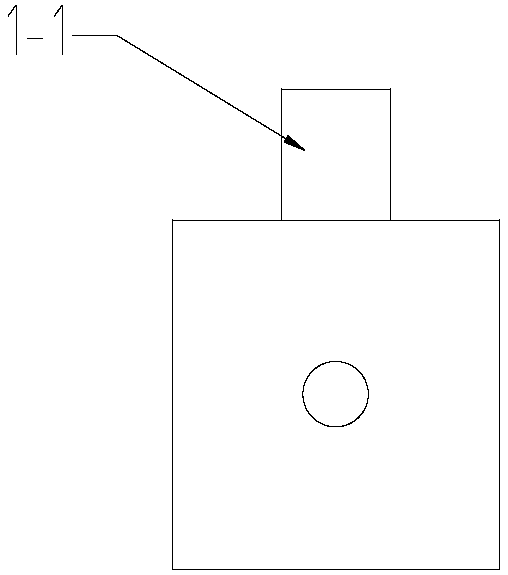

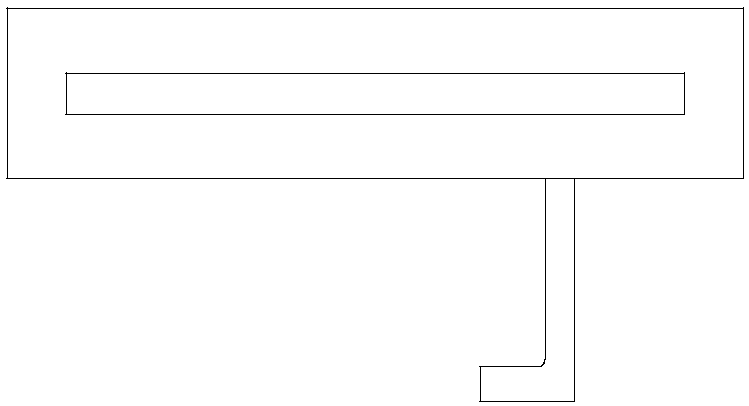

[0022] An adjustable hanger for shell parts, including a left hook assembly 3, a right hook assembly 2, a moving sleeve assembly 1 and a lifting ring 5; the moving sleeve assembly 1 is set on the right hook assembly 2, the left hook assembly 3 passes through the moving sleeve assembly 1 and is used in conjunction with the right hook assembly 2; the left hook assembly 3 adjusts the size of the hanging area 8 of the parts by sliding left and right; the wire rope 4 passes through The through hole of the left hook assembly 3 and the hanging part 1 - 1 of the mobile cover assembly 1 are finally connected on the suspension ring 5 .

[0023] Preferably, the moving sleeve assembly 1 fixes the left hook assembly 3 and the right hook assembly 2 through bolts;

[0024] Preferably, sliding grooves are provided on the upper and lower walls of the moving sleeve assembly 1 in the horizontal direction, so that the left hook assembly and the right hook assembly can wake up and slide in the sli...

Embodiment 2

[0029] This embodiment is all the same as embodiment 1 except the following features.

[0030] The left hook assembly 3 is provided with a handle 7, through which the sliding of the left hook assembly 3 is controlled to control the movement of parts in the suspension area.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com