System and method for detecting anti-cheating oiling machines

A fuel dispenser and anti-cheating technology, applied in special distribution devices, packaging, dispensing devices, etc., can solve the problems of uneven anti-cheating effects of fuel dispensers, no anti-cheating technology, and fuel dispenser cheating, etc., to protect the quantity and quality. , automatic output results, easy to operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

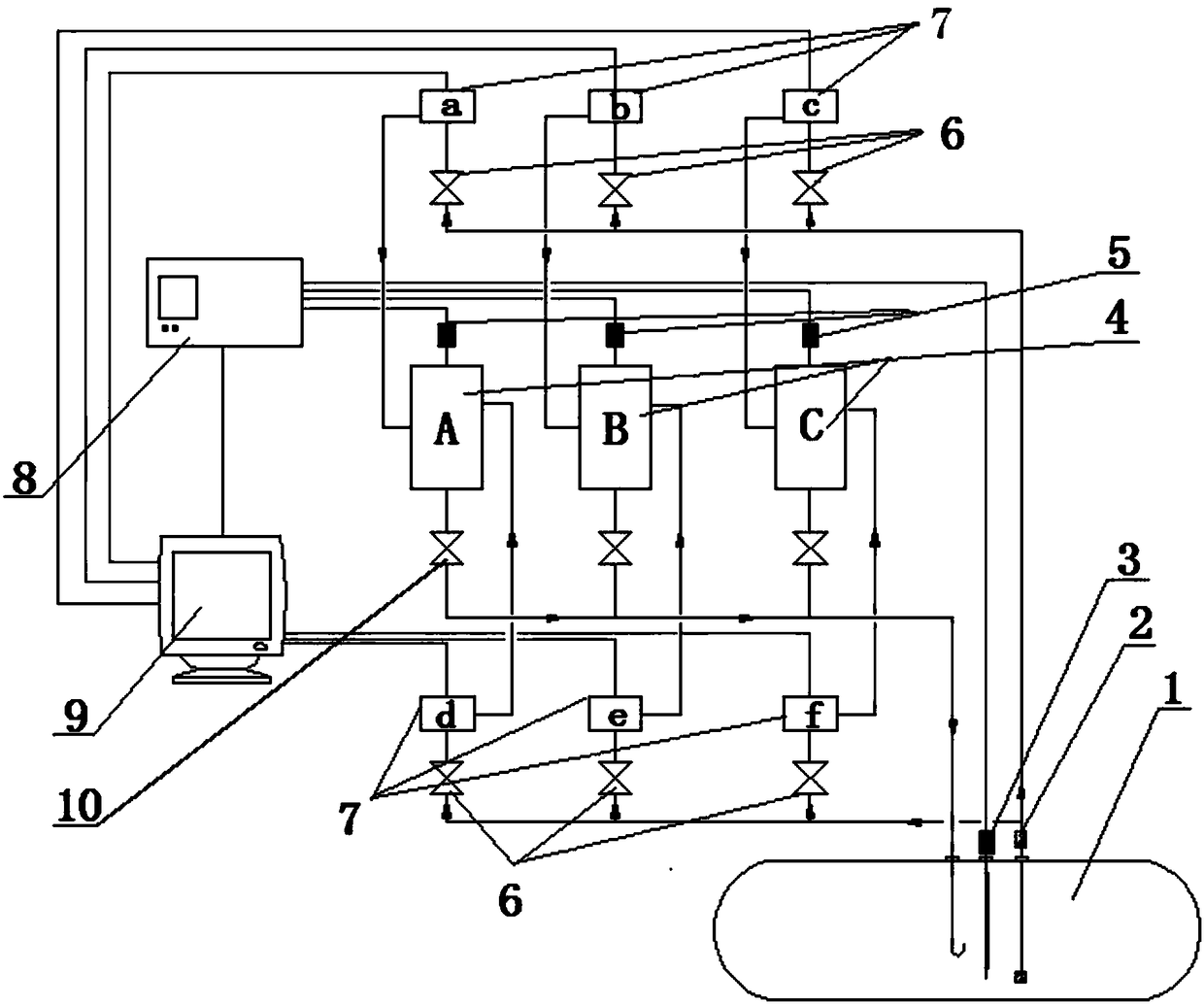

[0028] The tanker base 7 is a, which is used to install the anti-cheating tanker, and the standard container 4 is an A standard container with a capacity of 20L, which is used for the standard metering of oil products. During the test, install the fuel dispenser under test on a, connect the fuel inlet pipe of the dispenser, the control line of the oil gun, the control line of the motor solenoid valve, and the communication line of the tax declaration port of the dispenser, and then power on the dispenser. Start the automatic testing software on the detection computer 9. Start the submersible oil pump 2, and inject the test oil in the underground oil storage tank 1 into A after passing through the metering device of the fuel dispenser. The micro liquid level gauge 5 in A can test the amount of liquid flowing into A in real time, and transmit it to the detection computer 9 in real time. After reaching the preset value of the automatic test software, the detection computer 9 can...

Embodiment 2

[0030] The tanker base 7 is b, which is used to install the anti-cheating tanker, and the standard container 4 is a B standard container with a capacity of 100L, which is used for the standard measurement of oil products. During the test, install the fuel dispenser under test on b, connect the fuel inlet pipe of the fuel dispenser, the oil gun control line, the motor solenoid valve control line, and the communication line of the fuel dispenser tax declaration port, and then energize the fuel dispenser. Start the automatic testing software on the detection computer 9. Start the submersible oil pump 2, and inject the test oil in the underground oil storage tank 1 into B after passing through the metering device of the fuel dispenser. The micro liquid level gauge 5 in B can test the amount of liquid flowing into B in real time, and transmit it to the detection computer 9 in real time. After reaching the preset value of the automatic test software, the detection computer 9 can cl...

Embodiment 3

[0032] The tanker base 7 is c, which is used to install the anti-cheating tanker, and the standard container 4 is a C standard container with a capacity of 500L, which is used for the standard measurement of oil products. During the test, install the fuel dispenser under test on c, connect the oil inlet pipe of the dispenser, the control line of the oil gun, the control line of the motor solenoid valve, and the communication line of the tax declaration port of the dispenser, and then power on the dispenser. Start the automatic testing software on the detection computer 9. Start the submersible oil pump 2, and inject the test oil in the underground oil storage tank 1 into C after passing through the metering device of the fuel dispenser. The micro liquid level gauge 5 in C can test the amount of liquid flowing into C in real time, and transmit it to the detection computer 9 in real time. After reaching the preset value of the automatic test software, the detection computer 9 c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com