Reducing device and reducing method of quartz glass rod

A quartz glass rod and diameter reduction technology, applied in glass forming, glass manufacturing equipment, manufacturing tools, etc., can solve the problems of complex airflow movement, interference of reducing diameter rods, oxidation of graphite materials, etc., and achieve a clear and clean exhaust system. Controllable, deformable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

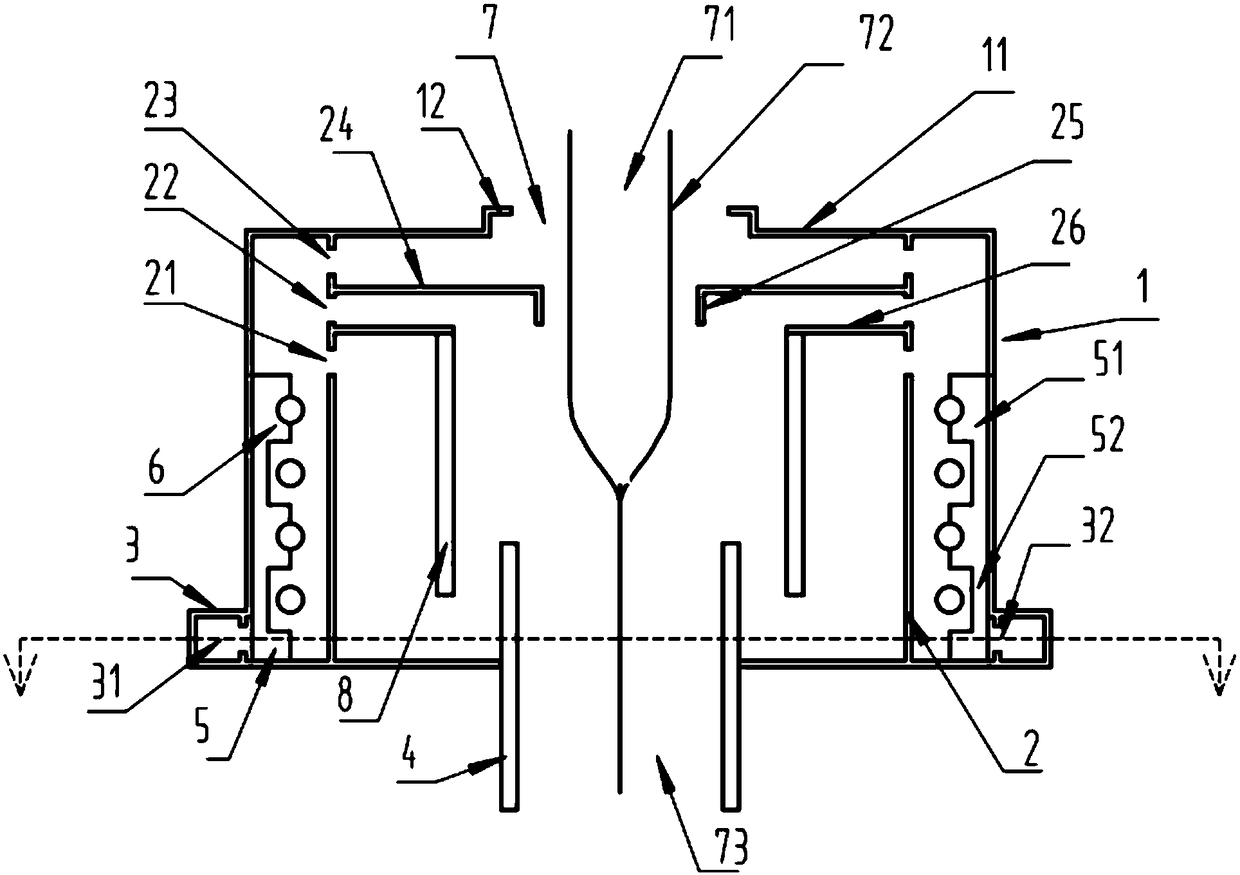

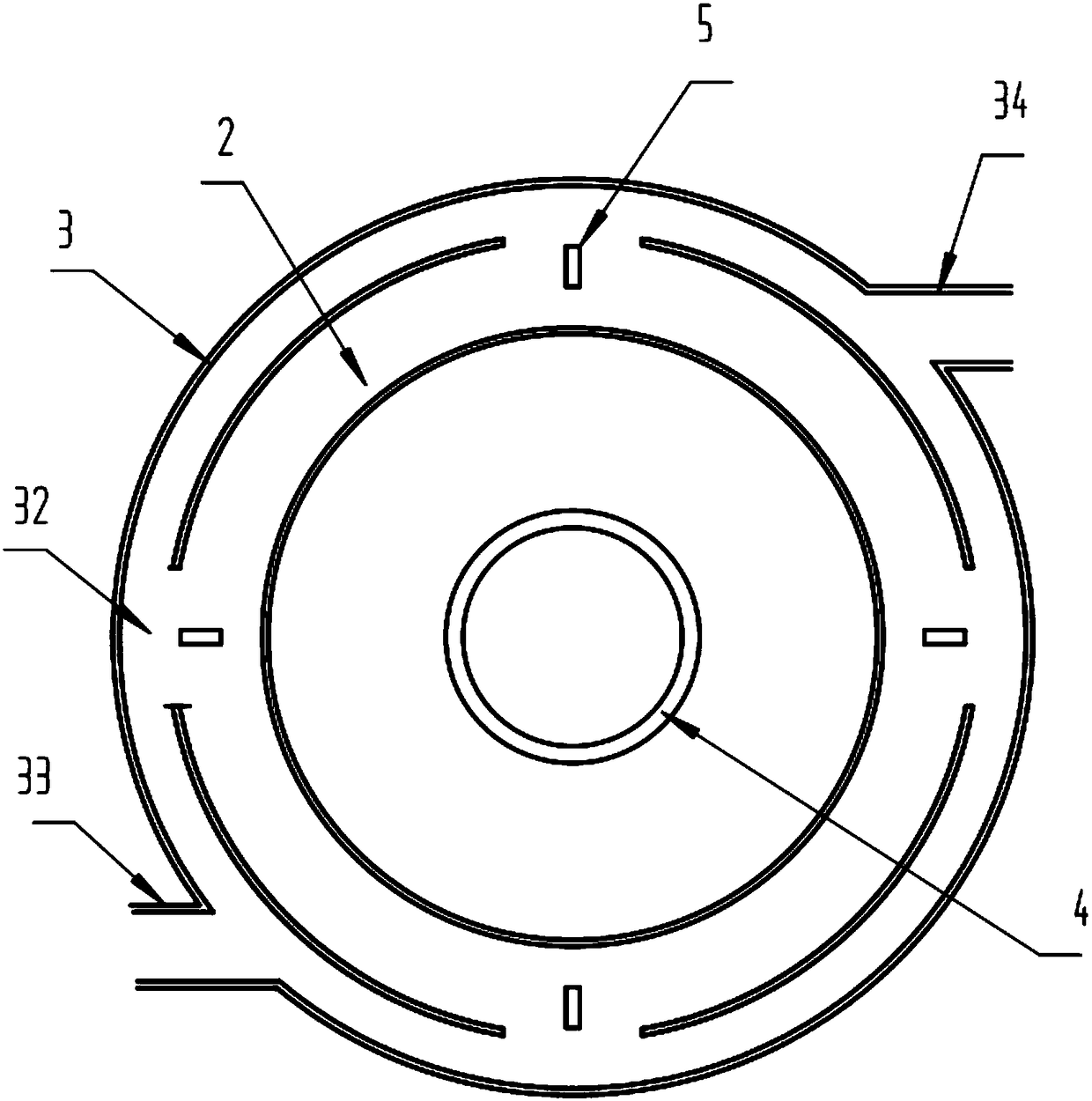

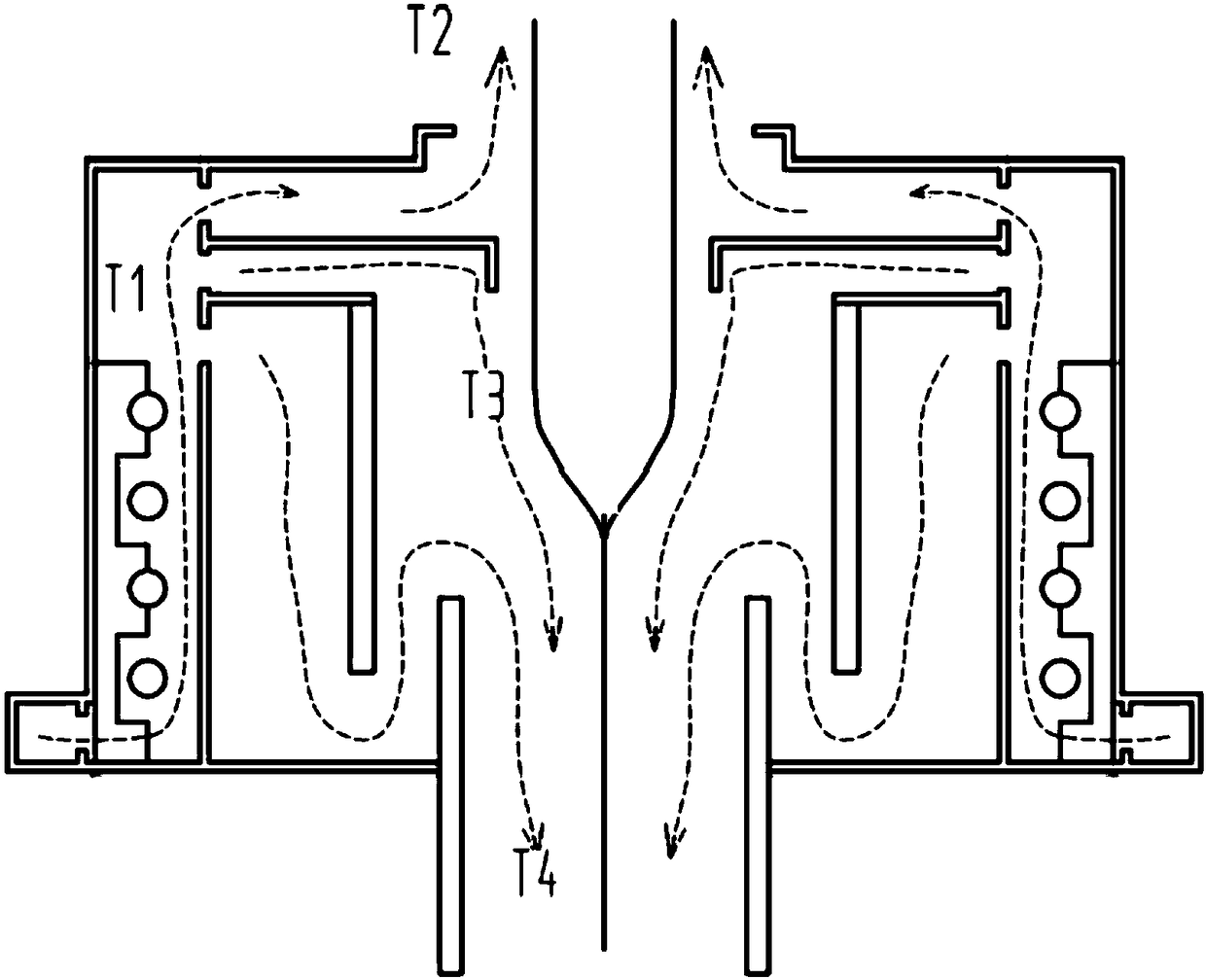

[0025] see figure 1 , a diameter reducing device for quartz glass rods, which includes a melting furnace and traction equipment, the traction equipment is used to pull rods, the melting furnace includes a cylindrical outer shell 1 and a cylindrical inner shell 2, the outer shell 1 and the inner shell 2 The upper end is connected by the upper cover plate 11, and the lower end is connected by the lower cover plate. There is an annular gas distribution chamber between the outer shell 1 and the inner shell 2 for distributing protective gas. The upper cover plate 11 is provided with an upper exhaust port at the center. 12. The center of the lower cover plate is fixed with an air retaining pipe 4, and the inner casing 2 is provided with a third air outlet 23, a second air outlet 22, and a first air outlet 21 in sequence from the upper cover 11 to the lower cover side. The inner side of the housing 21 is also fixed with a partition plate 24 and a carrier plate 26, and also includes a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com