Production method as well as application of 5A03 aluminum alloy ingots and 5A03 aluminum alloy ingots

An aluminum alloy ingot casting and production method technology, which is applied in the field of alloy processing, can solve the problems of complex wide-width casting technology and high technical requirements, and achieve the effects of reducing energy consumption, large passing flow rate, and improved degassing rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

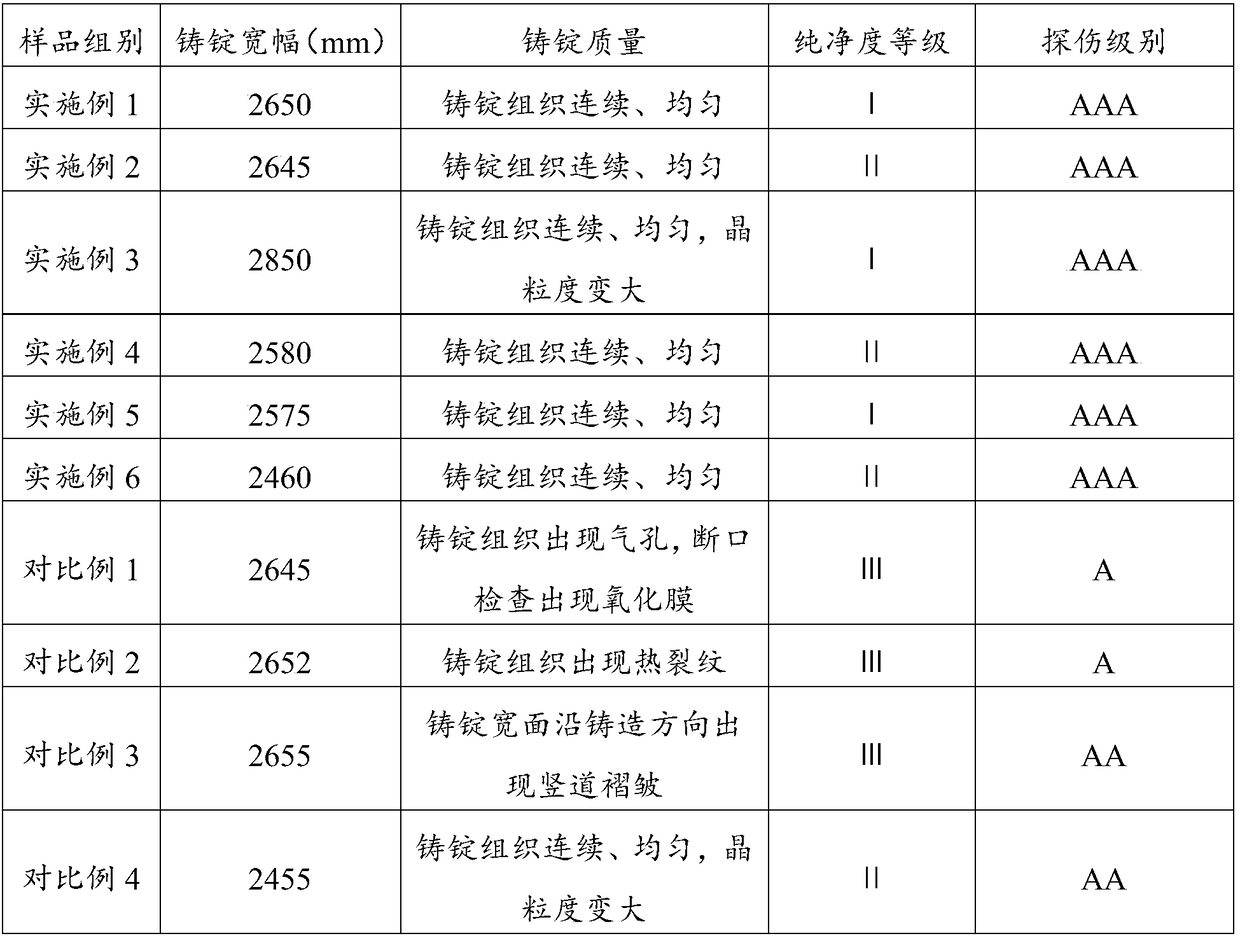

Examples

Embodiment 1

[0083] A kind of 5A03 aluminum alloy ingot production method provided in this embodiment comprises the following steps:

[0084] (a) Put aluminum alloy scraps and aluminum ingots for remelting into the melting furnace for melting, the weight ratio of aluminum alloy scraps and aluminum ingots for remelting is 0.1:1, then add Al-Si master alloy, Fe additive, Mn additive , pure Mg and other auxiliary materials for batching;

[0085] (b) Import the melt after batching into a tilting static furnace for refining, the refining temperature is 740 ° C, and the refining time is 40 minutes. After refining, the surface scum is cleaned and left for 30 minutes. ℃;

[0086] (c) Pass the melt converter after standing still through the primary filter system, online refining machine, four-rotor continuous degassing device and secondary filter system in sequence, and then pour it into the casting crystallizer for casting. The casting temperature is 695°C. The casting speed is controlled at 45m...

Embodiment 2

[0089] In the method for producing a 5A03 aluminum alloy ingot provided in this embodiment, except that the weight ratio of the aluminum alloy scrap to the aluminum ingot for remelting in step (a) is 1:5, the remaining steps and process parameters are the same as in Embodiment 1.

Embodiment 3

[0091] In the method for producing a 5A03 aluminum alloy ingot provided in this embodiment, except that the casting speed in step (c) is controlled at 55 mm / min, other steps and process parameters are the same as those in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap