Self-partitioning pressure-superposed water supply system for high-rise building and water supply method

A superimposed water supply and self-zoning technology, applied in water supply pipeline systems, water supply devices, water supply main pipelines, etc., can solve the problems of low working efficiency, energy waste, power consumption and other problems of secondary pressure equipment, so as to improve water supply efficiency, The effect of reducing power consumption and reducing equipment wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

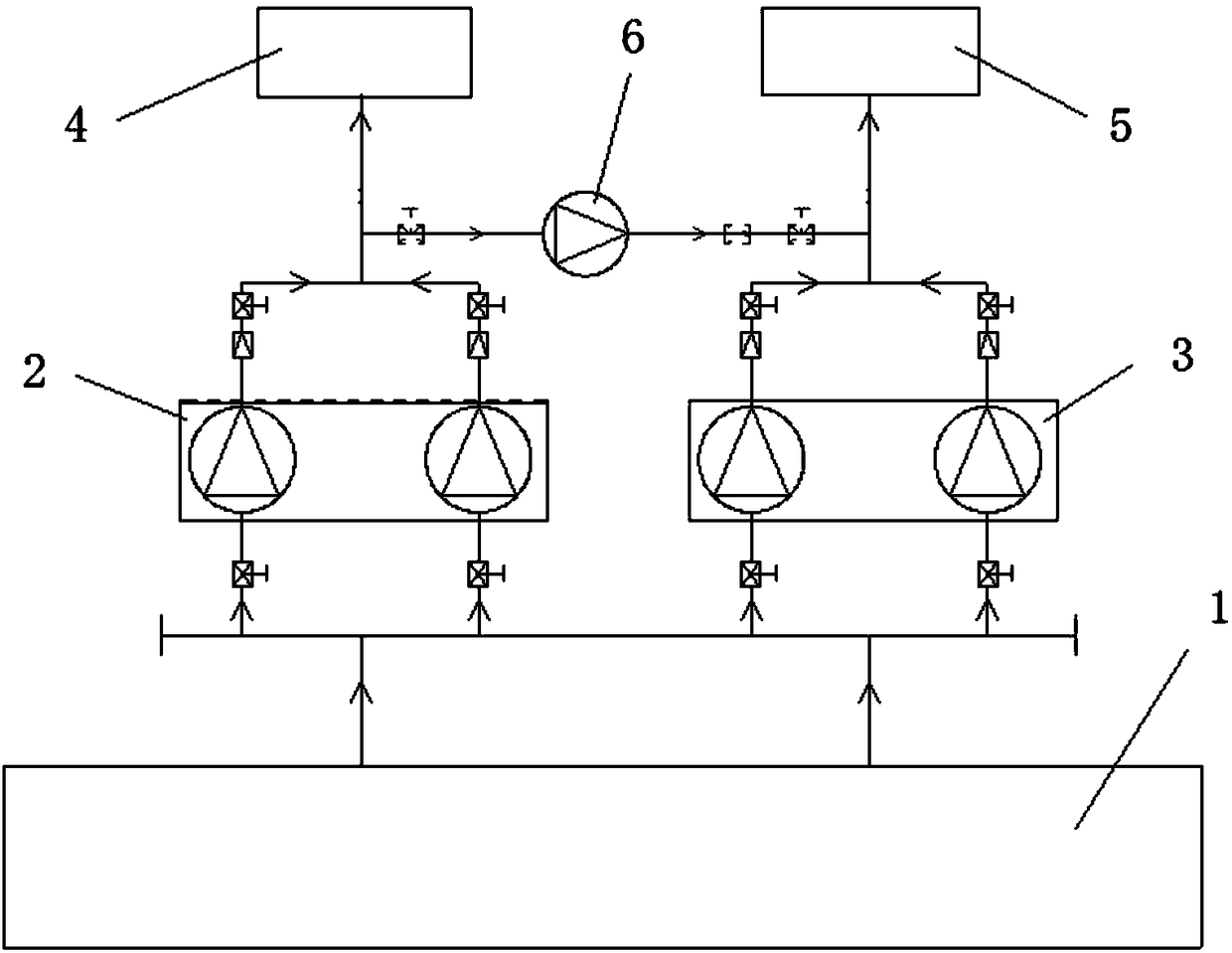

[0036] like figure 1 As shown, a building has a total of 14 floors, and the specific implementation steps are as follows:

[0037] (1) High-rise buildings are divided into low-pressure zone 4 (1-9 floors) and high-pressure zone 5 (10-14 floors) according to the floor height. Wherein, the low pressure area 4 is equipped with water pump group 1 2, and the high pressure area 5 is equipped with water pump group 2 3, and their water inlets are all connected to the water storage tank 1; Small flow water pump-6.

[0038] (2) In the low peak period of water consumption, the water pump group 23 is closed, the water pump group 12 and the small flow pump 16 are turned on, the water supply of the low pressure area 4 is provided by the water pump group 12; the water supply of the high pressure area 5 is sucked by the small flow water pump 16 1.2 The water on the water outlet side is provided after superimposing its water supply pressure.

[0039] (3) During the peak period of water cons...

Embodiment 2

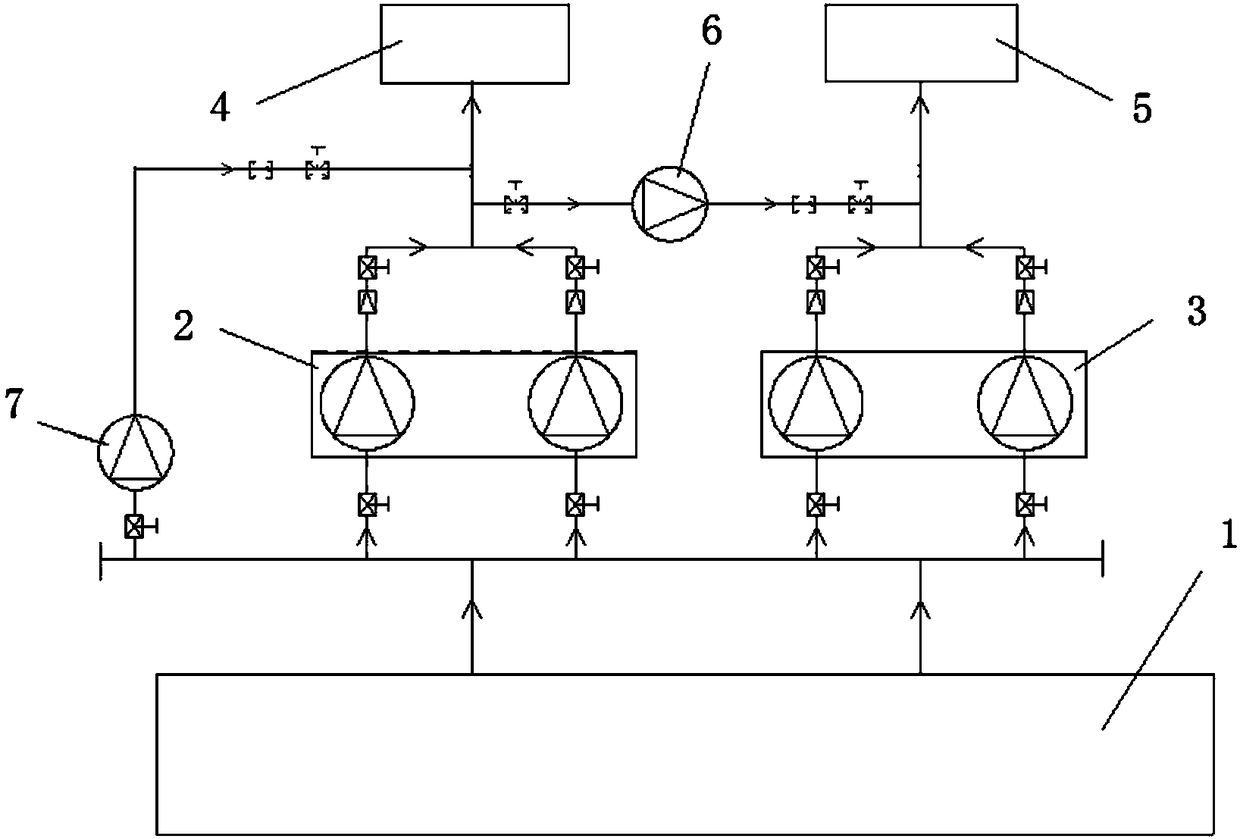

[0043] like figure 2 As shown, the difference from Embodiment 1 is that the outlet side of the water storage tank 1 and the water pump group one 2 is connected to the pipeline through the small flow water pump four 7, and in the low peak period of water use, the water pump group one 2 and the water pump group two 3 Closed, small flow pump 1 6 and small flow pump 4 7 are turned on, low-pressure area 4 is supplied by small-flow pump 4 7; high-pressure area 5 is supplied by small-flow pump 1 6 to absorb water from the outlet side of small-flow pump 4 7 and overlap Its water supply pressure is provided later, and the power saving effect is further improved.

Embodiment 3

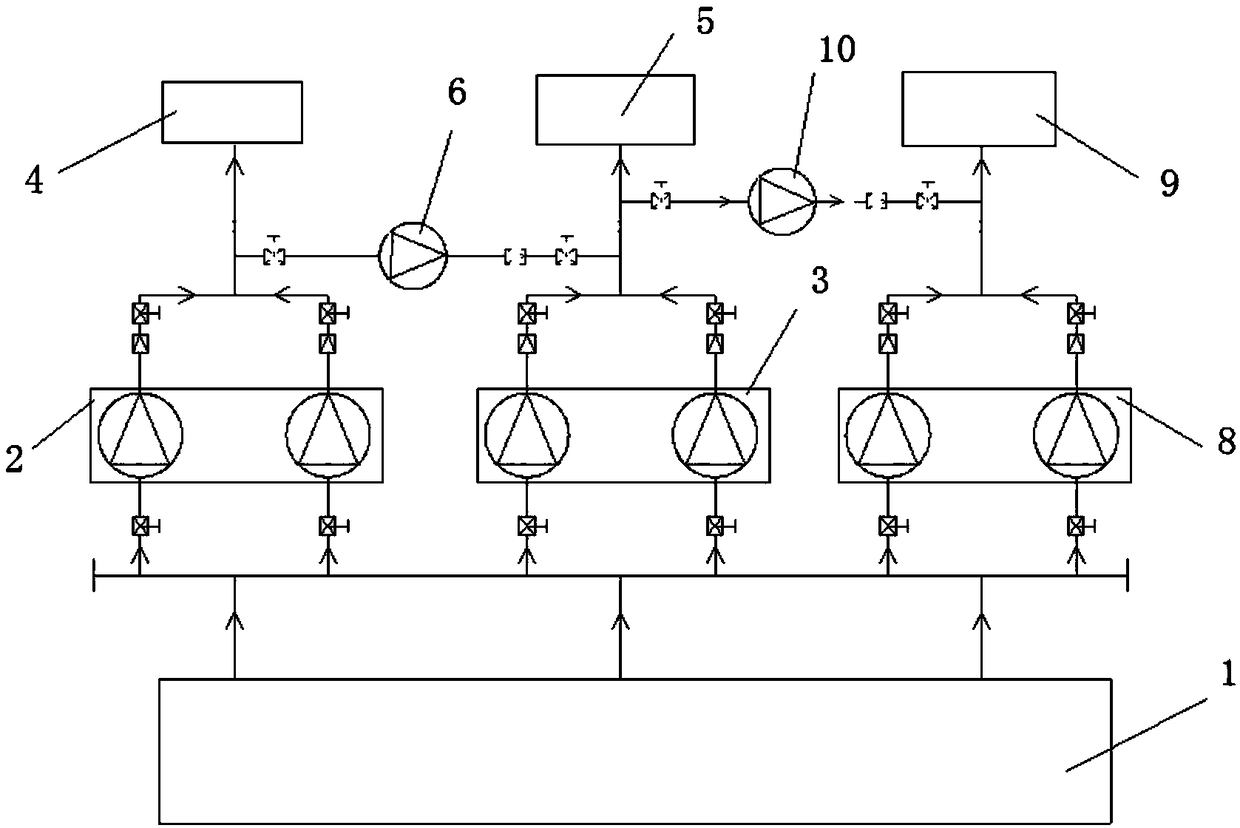

[0045] like image 3 As shown, a business hotel has a total of 28 floors, and the specific implementation steps are as follows:

[0046] (1) Divide high-rise buildings into low-voltage zone 4 (1-9 floors), high-voltage zone 5 (10-19 floors), and high-voltage zone 9 (20-28 floors) according to the floor level. Wherein, low-pressure zone 4 is equipped with water pump group one 2, high-pressure zone 5 is equipped with water pump group two 3, and high-pressure zone 9 is equipped with water pump group three 8, and their water inlets are all connected to water storage tank 1; A small flow water pump one 6 is equipped between the water outlets of the water pump group two 3; a small flow water pump three 10 is arranged between the water outlets of the water pump group two 3 and the water pump group three 8 outlets.

[0047] (2) During the low peak period of water consumption, the water pump group 2 3 and the water pump group 3 8 are closed, the water pump group 1 2, the small flow wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com