External corner module and assembly method thereof

A technology of male corners and female corners, applied in the field of male corner modules and their assembly, can solve the problems of low efficiency in the installation process of male corners, achieve the effects of increased anti-deformation ability, improved installation efficiency, and fast and efficient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

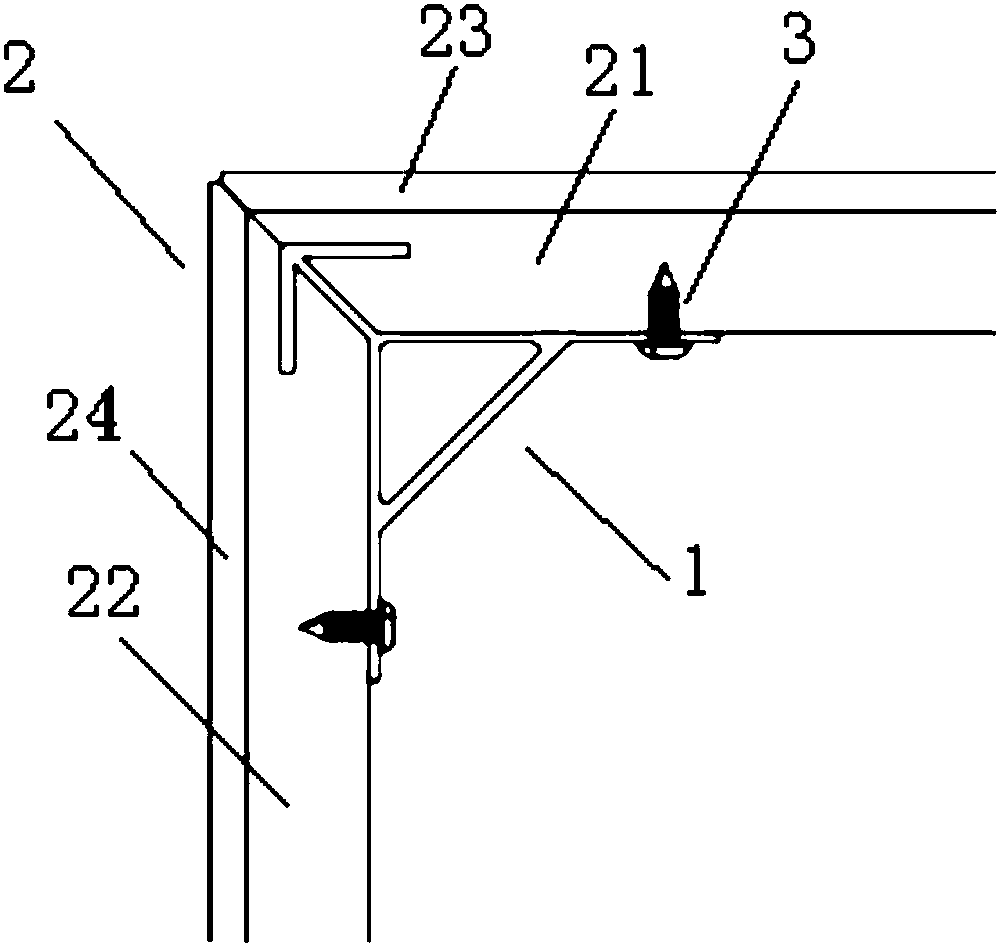

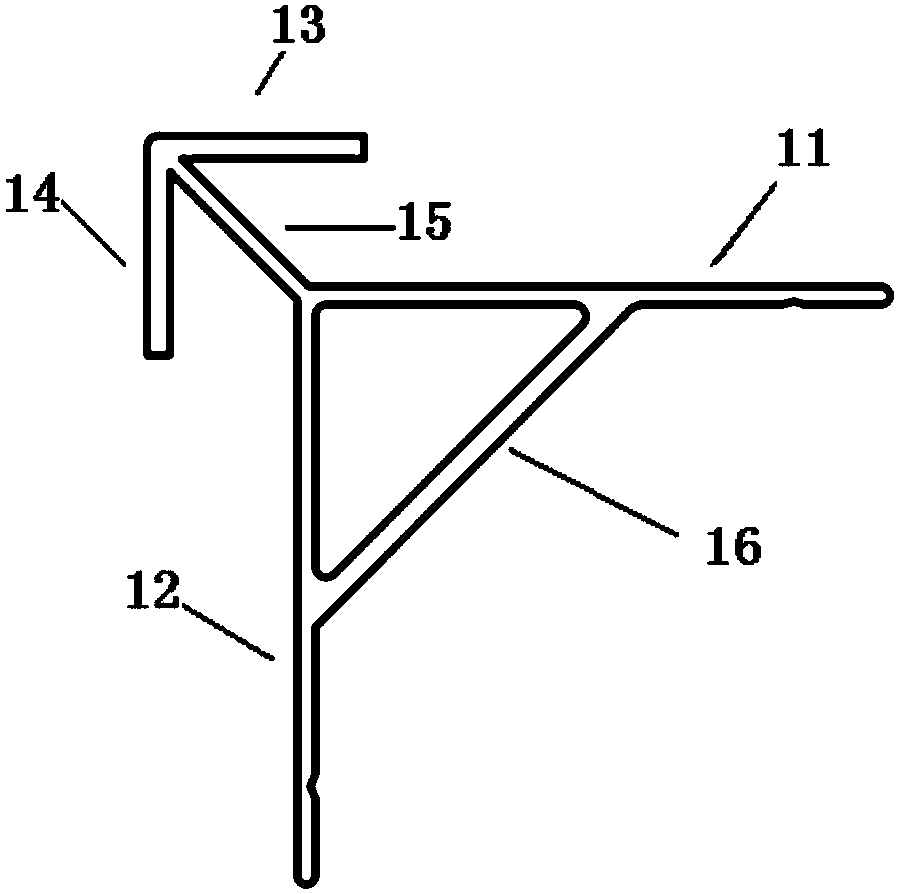

[0050] This embodiment provides a male corner module, such as figure 1 As shown, it includes the first male corner board, the second male corner board and the male corner connector 1. Wherein, the first external corner panel includes a first external corner wall panel 21 and a first external corner panel 23 attached to the first external corner wall panel 21; the second external corner panel includes a second external corner panel The corner wall panel 22 and the second male corner panel 24 attached to the second male corner wall panel 22; the first end surface of the first male corner wall panel 21 is a bevel, and a first card slot is formed on it ; The first end face of the second male corner wall panel 22 is an inclined plane, on which a second card slot is formed; the first end face of the first male corner wall board 21 and the second male corner wall board 22 are The second end surface is attached to each other; the first end surface of the first male corner panel 23 is...

Embodiment 2

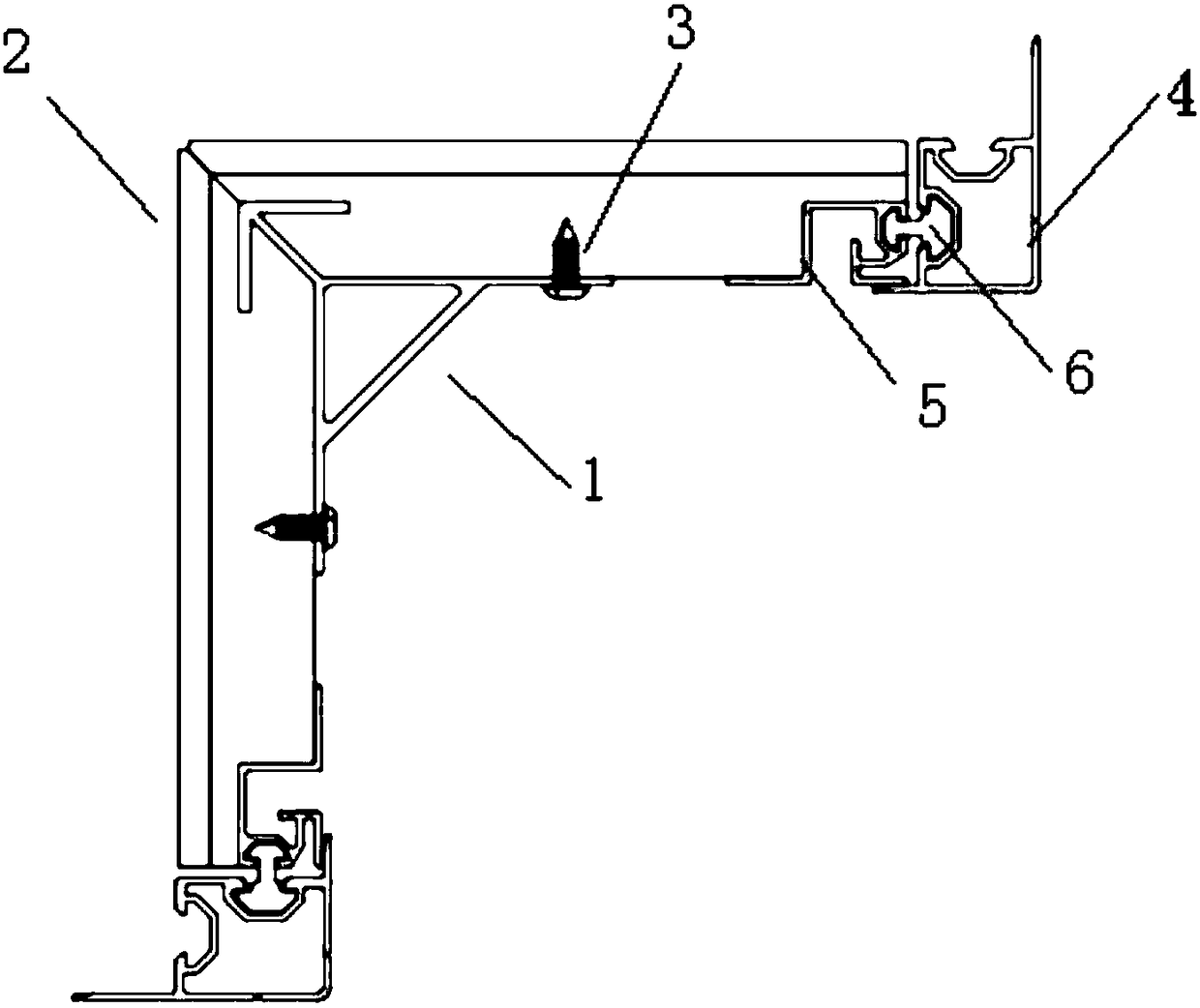

[0060] The male angle module provided in this embodiment, on the basis of various schemes in Embodiment 1, such as image 3 As shown, it also includes a clamping piece 5 , an inserting piece 6 and a female corner clamping piece 4 . Among them, such as Figure 4 As shown, the female corner clip 4 includes a female corner clip and a locking part 43 arranged in the female corner clip; the female corner clip includes a first limiting plate 41 and a second limiting plate 42, the first end surface of the first limiting plate 41 is connected to the first end surface of the second limiting plate 42; the engaging portion 43 includes a first surface parallel to the first limiting plate 41 As well as the second surface parallel to the second limiting plate 42 , a second insertion groove 44 is formed on the first surface thereof. As a preferred solution, a third insertion groove 45 is formed on the second surface of the engaging portion 43, the second insertion groove 45 has the same st...

Embodiment 3

[0068] This embodiment provides a method for assembling an external corner module, including the following steps:

[0069]Step 1: Insert the third edge trimming board in the male corner connector into the first slot in the first male corner wall panel, so that the first edge trimming board in the male corner connector and the first male corner wall board Surface fit, the first end surface of the first wall panel abuts against one side of the connecting plate; Step 2: Insert the fourth side panel in the male corner connector into the second card slot in the second male corner wall panel , so that the second side panel in the male corner connector fits the surface of the second male corner wallboard, and the first end surface of the second wallboard abuts against the other side of the connecting board; the first male corner panel and the second The male corner panels form a male corner after abutting against each other.

[0070] The structure of the male corner connector is as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com