Centrifugal type friction damper

A friction damper, centrifugal technology, applied in friction dampers and other directions, can solve the problems of oil leakage, hydraulic damper damping force and temperature, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

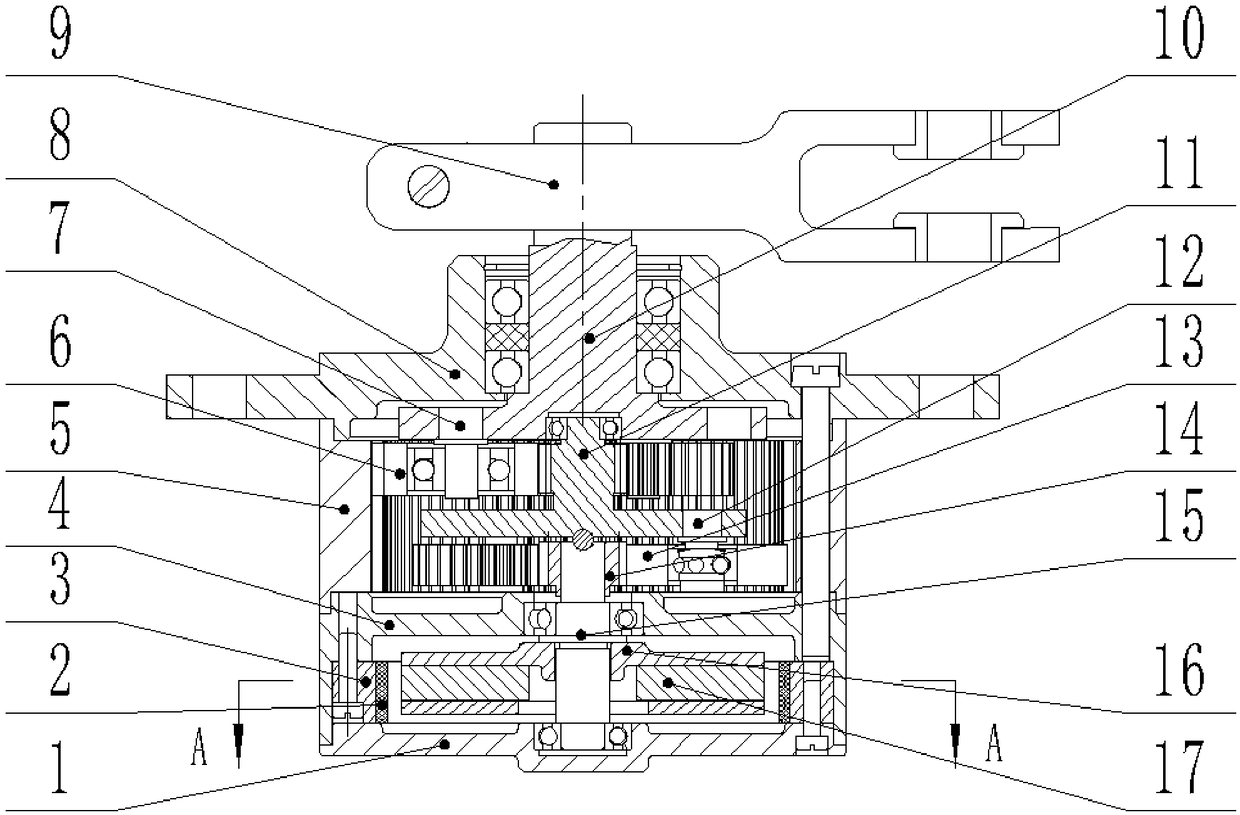

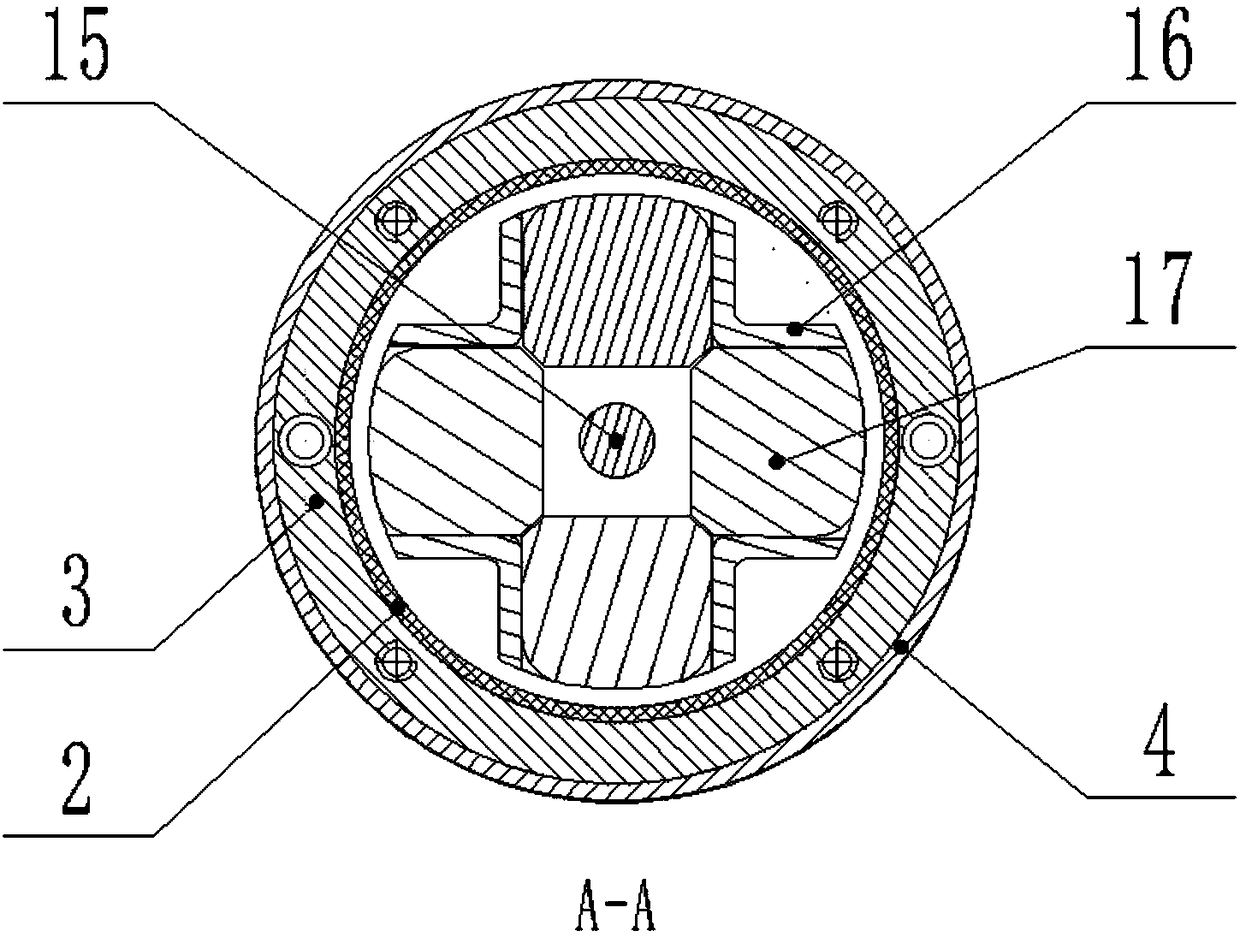

[0013] Below in conjunction with accompanying drawing, the present invention will be further described:

[0014] The centrifugal friction damper is characterized in that: the damper includes a two-stage planetary speed increase, the input shaft 10 is supported and fixed on the front end cover 8, and three pin shafts 7 are pressed on the input shaft 10, and three planetary gears 6 are installed through bearings , the three planetary gears 6 mesh with the inner ring gear 5 and the outer ring teeth of the planetary carrier 11 at the same time, and the three planetary gears 6, the inner ring gear 5 and the outer ring teeth of the planetary carrier 11 form a first-stage planetary gear speed-up; the planetary carrier 11 There are three pin shafts 12 on the upper press, and three planetary gears 13 are installed through the bearings. The three planetary gears 13 mesh with the ring gear 5 and the shaft gear 14 at the same time. The three planetary gears 13, the ring gear 5 and the shaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com