Speed reduction device combined with motor

A technology for reduction gears and motors, which is applied to electromechanical devices, transmission devices, transmission device parts, etc., and can solve the problems of the optimal combination of tooth number differences, such as unclear teaching, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

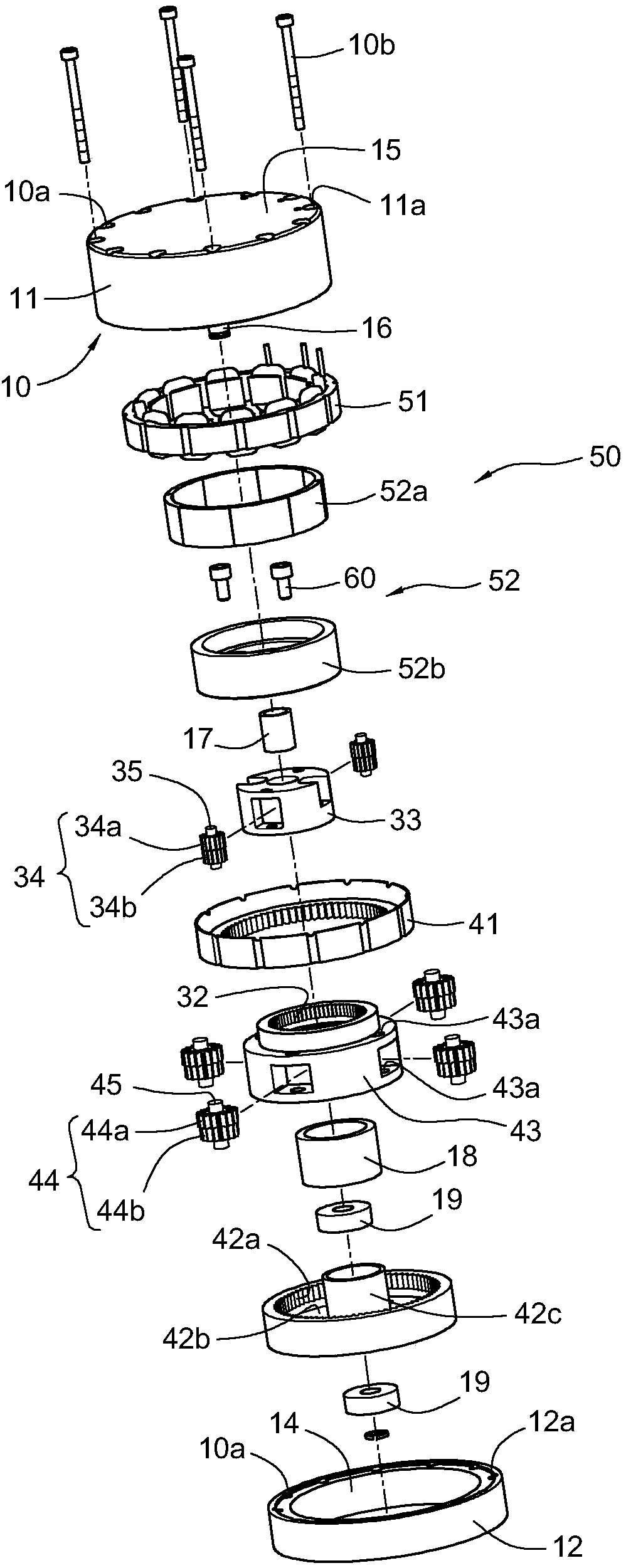

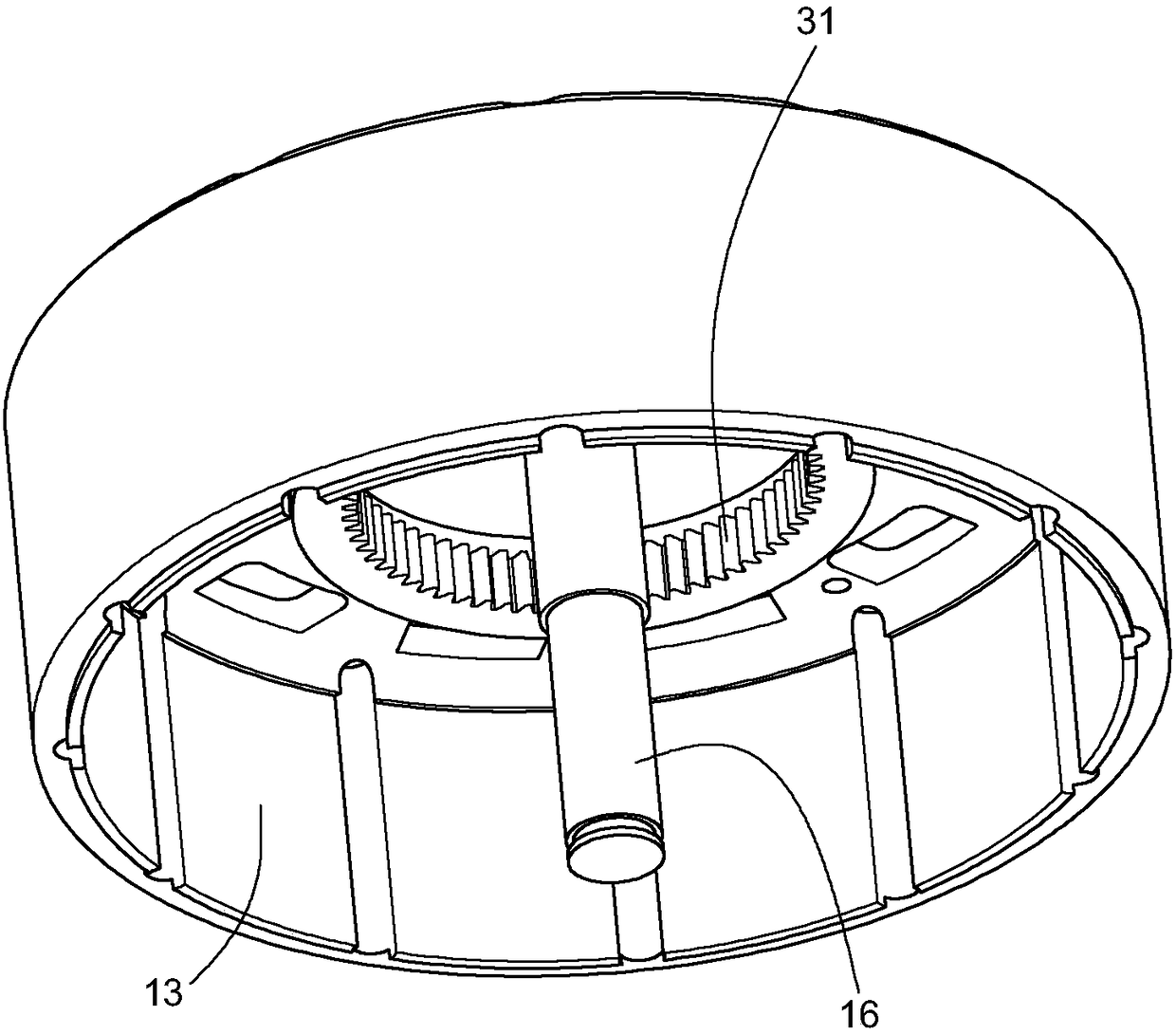

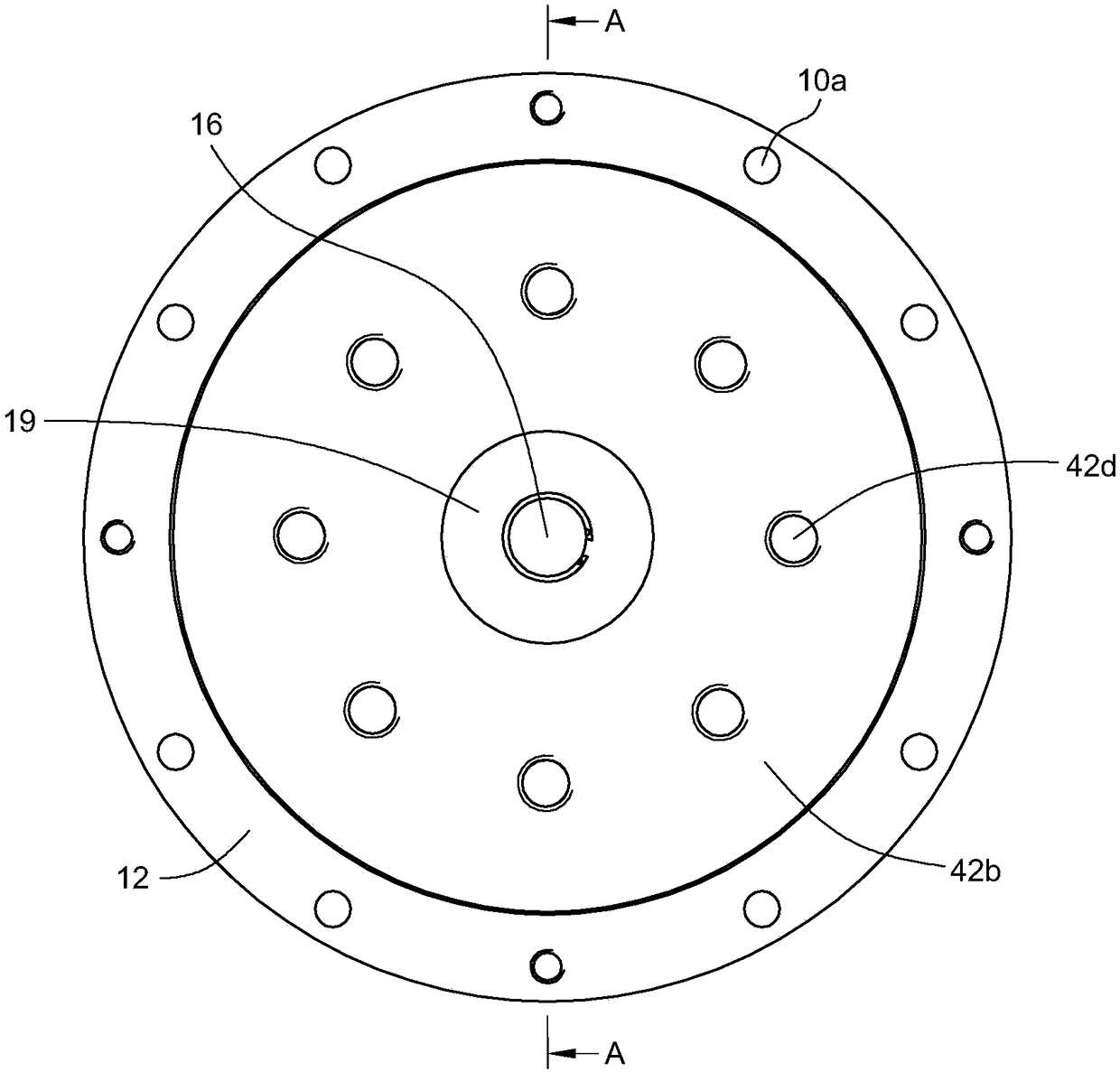

[0041] First, please refer to Figure 1 to Figure 6 , To disclose the configuration details of a preferred embodiment of the present invention, and explain the motor-combined deceleration device, or motor deceleration device, provided by the present invention. Its structure includes a housing 10, a support shaft 16, and a reducer 20. And a hollow motor 50.

[0042] by figure 1 and Figure 4 It can be seen that the casing 10 includes a first casing 11 and a second casing 12. A plurality of through holes 11a are formed on the peripheral edge of the first shell cover 11, and a corresponding number of screw holes 12a are formed on the peripheral edge of the second shell cover 12. The first shell cover 11 is connected to the first shell cover 11 with a corresponding number of screws 10b. The second shell cover 12 is assembled relative to the screw assembly to form a housing 10. Both ends of the casing 10 are formed with a closed end surface 15 and an open hole 14 respectively; wherei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com