Pinch valve

A technology of pinch valves and tubular valves, which is applied in the field of pinch valves, can solve problems such as wear and tear, and achieve the effects of improving precision, improving sealing functions, and increasing sealing force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

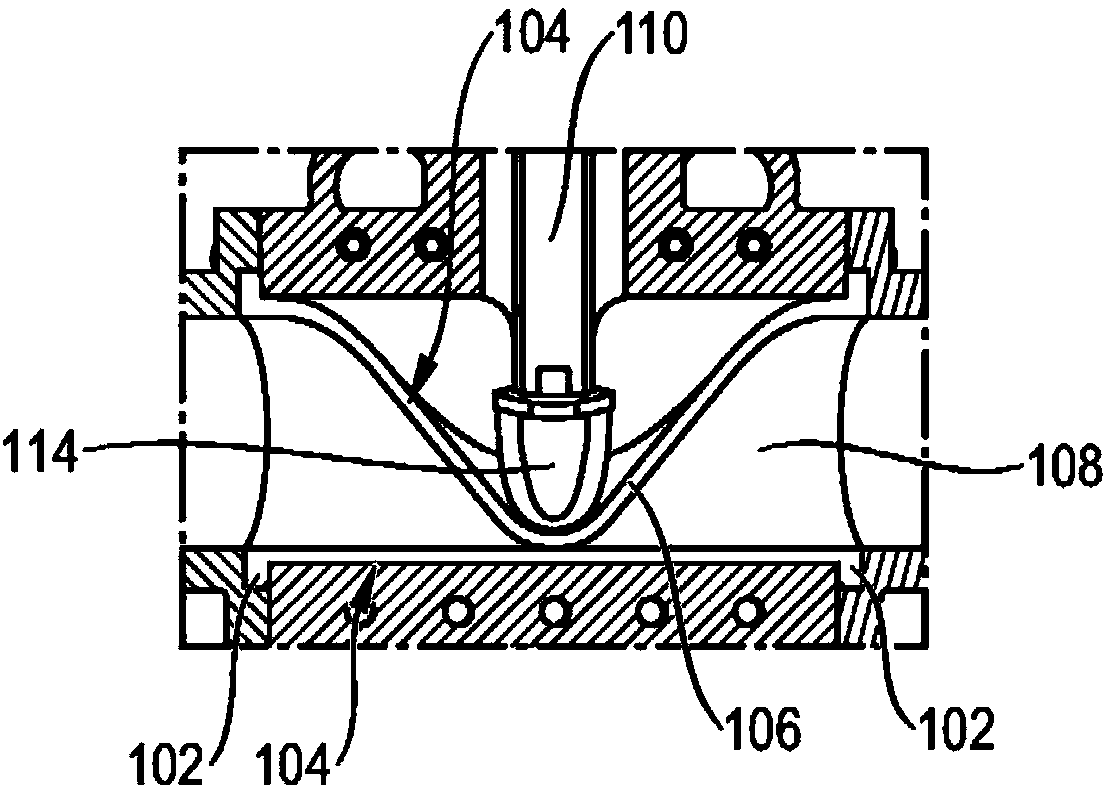

[0033] figure 1 A schematic diagram of a prior art pinch valve is shown. The pinch valve includes a valve member 106 that defines a flow passage 108 for fluid as a tubular member. A tubular valve member is arranged between two connecting elements 102 and comprises a flexible peripheral wall 104 . The pinch valve comprises a closure device 110 disposed on the outside of the peripheral wall 104 and designed to be switchable between an open position in which the flow channel 108 defines a state through which fluid can flow, and a closed position in which In the closed position, the flow channel 108 defines a closed state for fluid. The closure device 110 comprises a plunger element 114 designed to be switchable between an open position and a closed position by a translational movement. The closure device 110 comprises only a single plunger element 114, with the result that the tubular valve member 106 is subjected to particularly large deformations as well as large mechanical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com