Preheating or heating casing temperature measuring device in alumina production

A technology for heating sleeves and temperature measuring devices, which is applied in the direction of measuring devices, electric devices, and thermometers using electric/magnetic elements that are directly sensitive to heat, and can solve the problems of large errors in temperature measurement results, steam waste, and insulation damage and other issues, to achieve the effect of improving accurate judgment, improving accuracy, and protecting integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The embodiments of the invention will be described in detail below in conjunction with the accompanying drawings, and the scope of protection of the present invention is not limited by the embodiments.

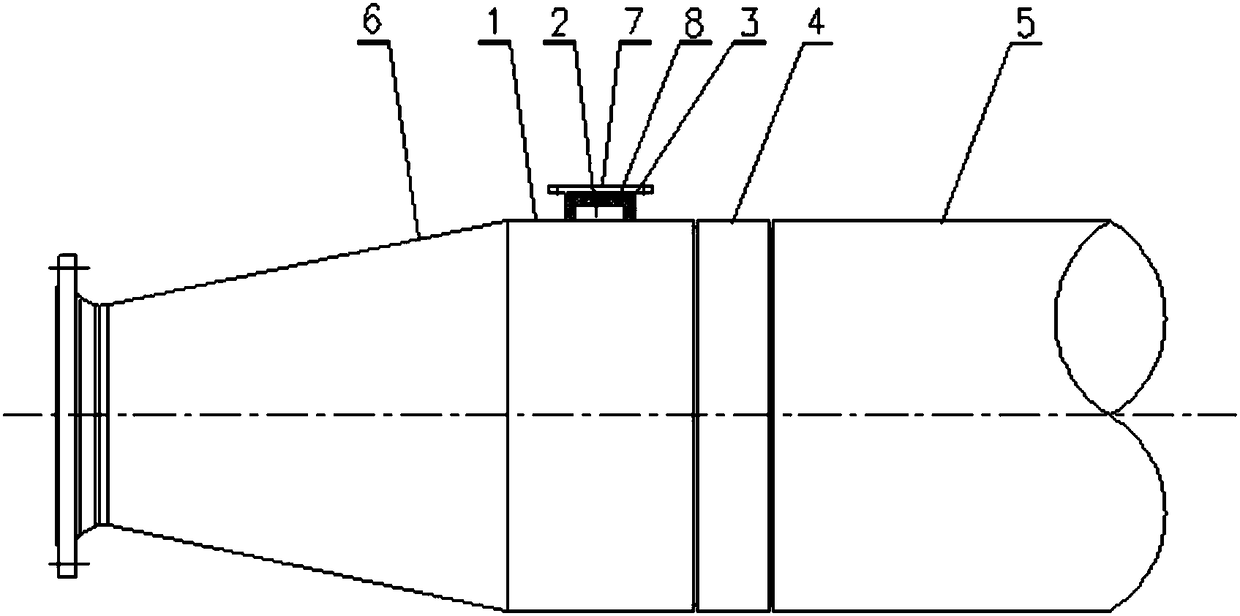

[0017] Such as figure 1 As shown, on the straight pipe section 1 with a length of 500mm between the casing plug 4 and the casing variable diameter 6 of the present invention, after the heat patch type thermal resistor 2 is fixed with screws, a protective box 3 is made with a steel plate around the thermal resistor. The steel plate is spot-welded with the outer wall of the pipe, and the connection port of the thermal resistance signal line is left. The upper edge is made of a steel plate to form a flange, and the protective box is filled with a composite silicate material 8, and the upper side is a flange made of a 6mm thick steel plate. The cover 7 is connected with the flange of the protection box with bolts.

[0018] The casing is one or more of single casing, three ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com