Novel optical lens measuring method

A technology of optical lens and measurement method, applied in the field of optical measurement, can solve the problems of complicated measurement system system, increase of measurement cycle, etc., and achieve the effects of large curvature measurement range, high precision and simple system structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described in detail below in conjunction with the accompanying drawings and through specific embodiments. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

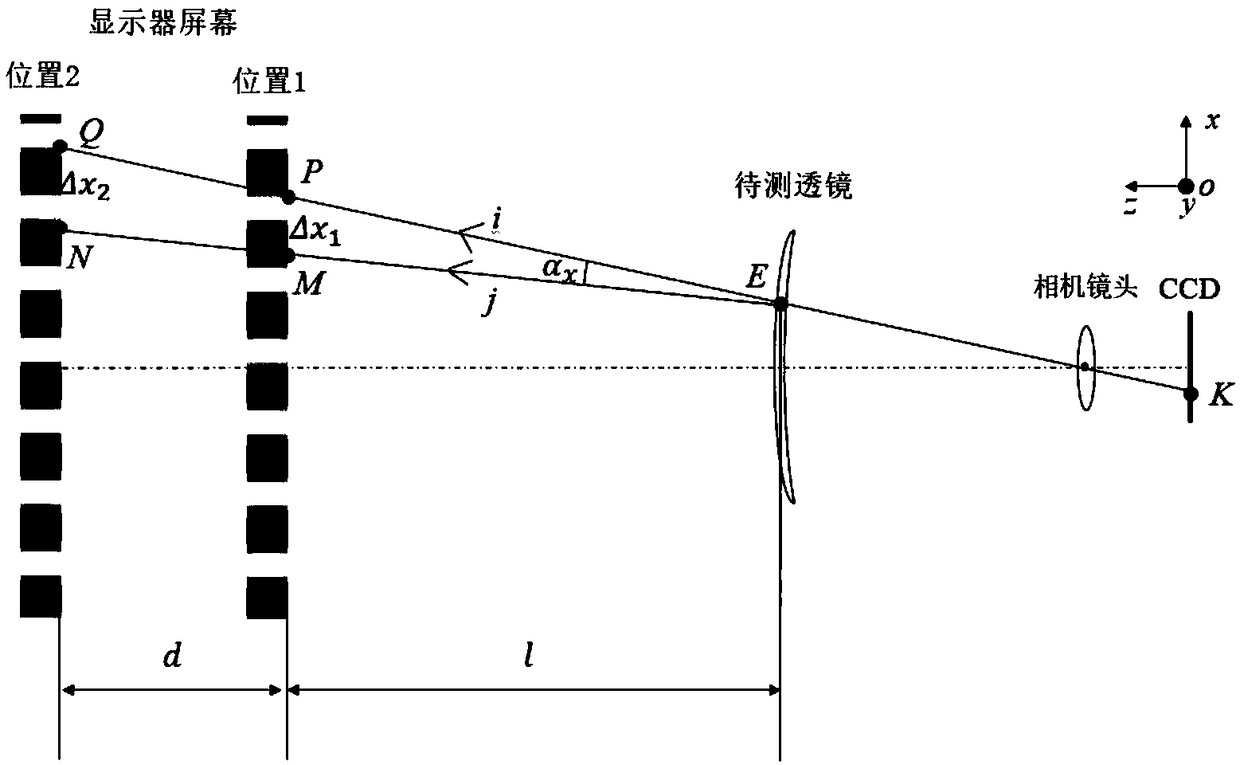

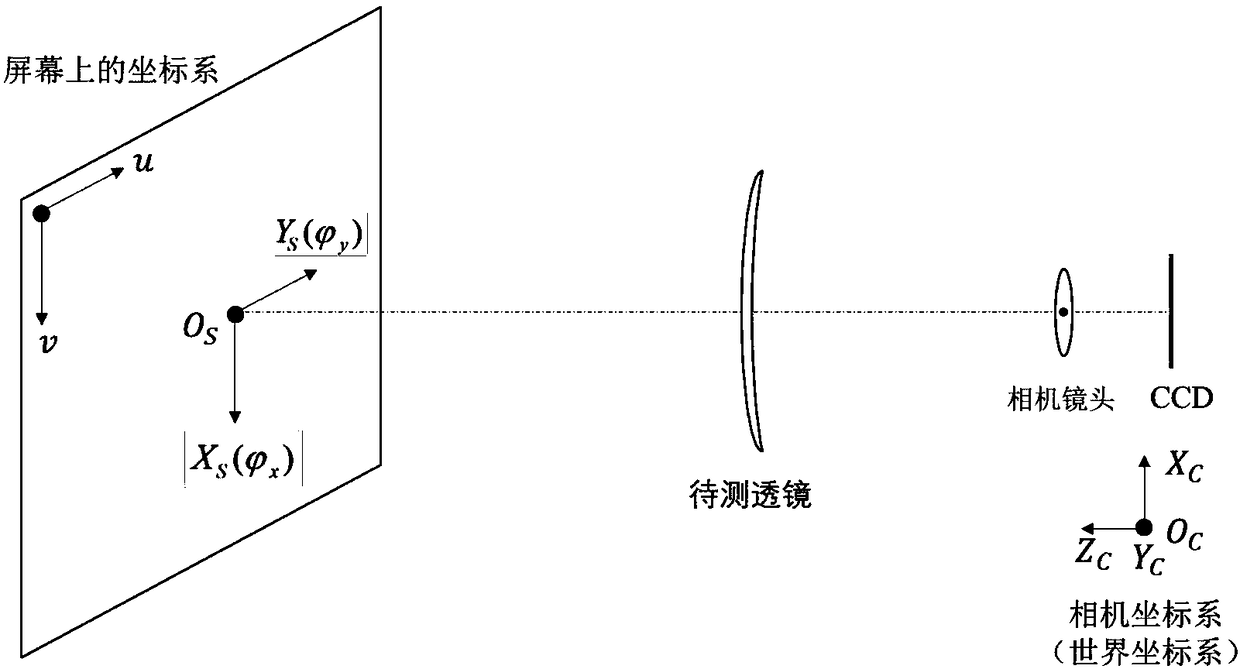

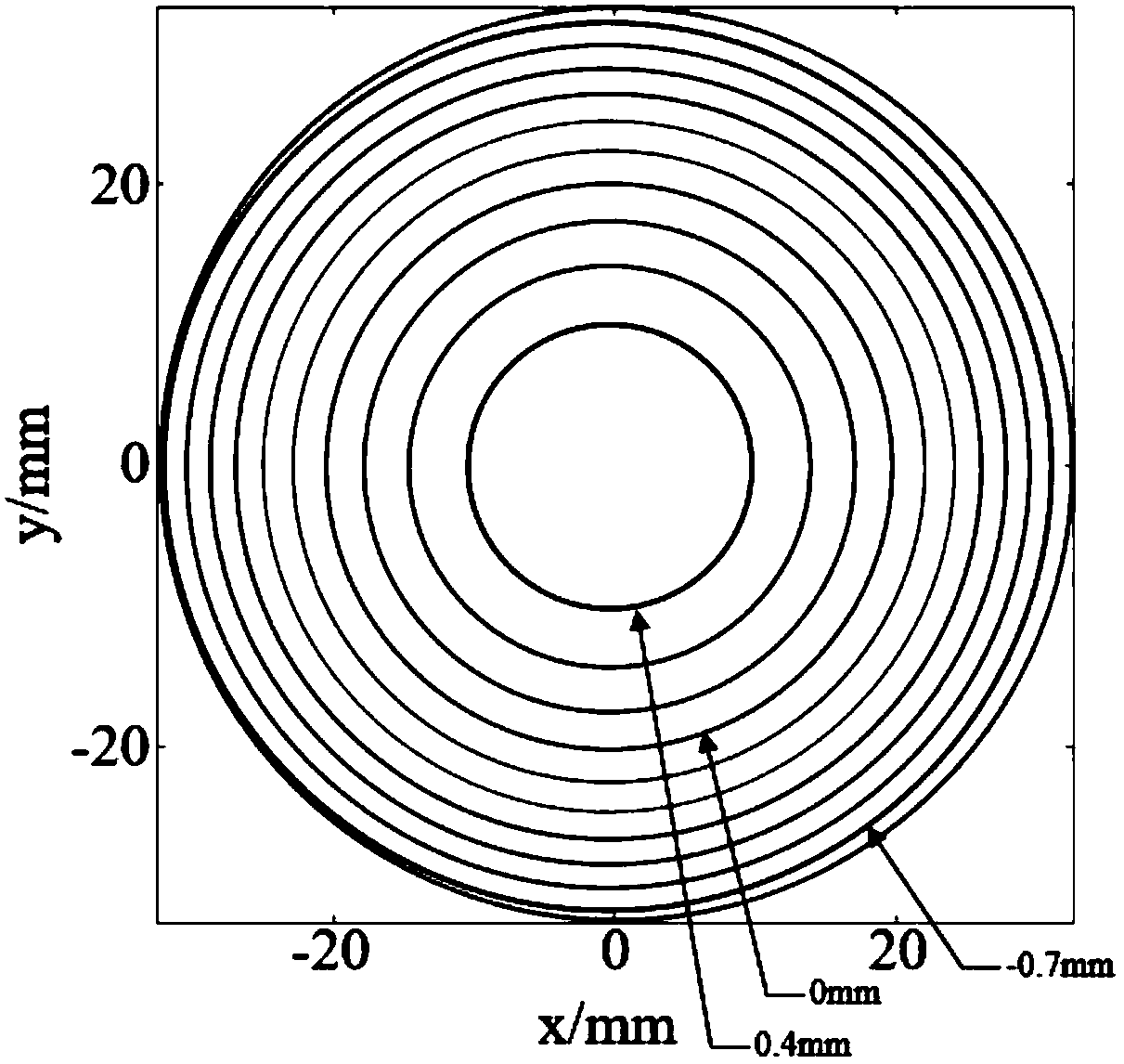

[0044] The optical lens measuring system that the present invention proposes is made up of the display of projection fringe and the CCD camera of collecting fringe, as figure 1shown. When the lens to be tested is placed between the display and the camera, the deflection of the light by the lens will distort the fringes collected by the CCD, and the phase shift method and phase resolution technology can be used to extract the fringes of each point collected by the camera. phase. With the help of phase and system calibration, the positions P and Q on the display screen before and after the same point on the camera CCD are added to the measuring lens, and the point E where the light is deflected on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com