Methods of setting a shaping machine

A molding machine and adjustment value technology, applied in the direction of control/regulation system, general control system, computer aided design, etc., can solve problems such as difficult to determine the injection molding process window, difficult to determine the optimal working point, etc., to achieve energy and time efficiency , time-saving, and stability-guaranteed effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

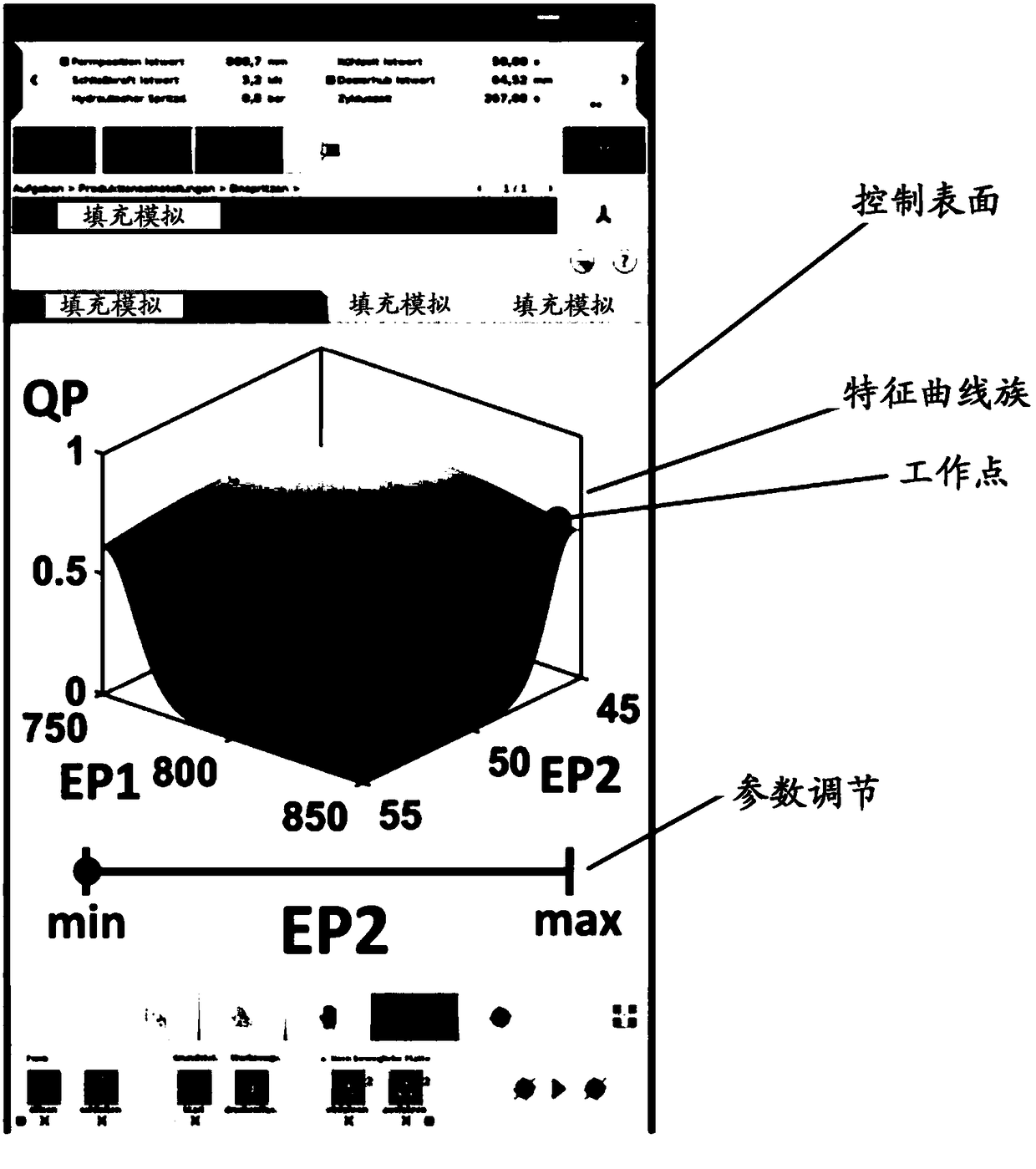

[0116] exist figure 1 An example of a corresponding visualization is shown in , which shows the display side of the control device in which the characteristic curves are displayed. The quality parameter QP is shown with respect to the control parameters EP1 and EP2. The operating points are plotted in the characteristic curves according to the currently selected values for EP1 and EP2. The value of this operating point can additionally be displayed separately. Likewise, a slide controller is shown, by means of which the value of the parameter can be changed. This value can act directly on the function of the machine or subsequently on its own instruction. Optionally, the value of the second parameter can be changed according to the input of the value of the first adjustment parameter, so as to maximize the value of the quality parameter according to the characteristic curve family.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com