Peelable glue coating composition, peelable glue coating and application thereof

A coating composition and stripping technology, applied in the coating and other directions, can solve the problem that the process protection of irregular-shaped metal parts cannot be satisfied, the peelable protective film coating is warped, and the stripping force of the strippable coating is small. and other problems, to achieve the effect of eliminating accidental shedding, improving yield and production efficiency, and increasing adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

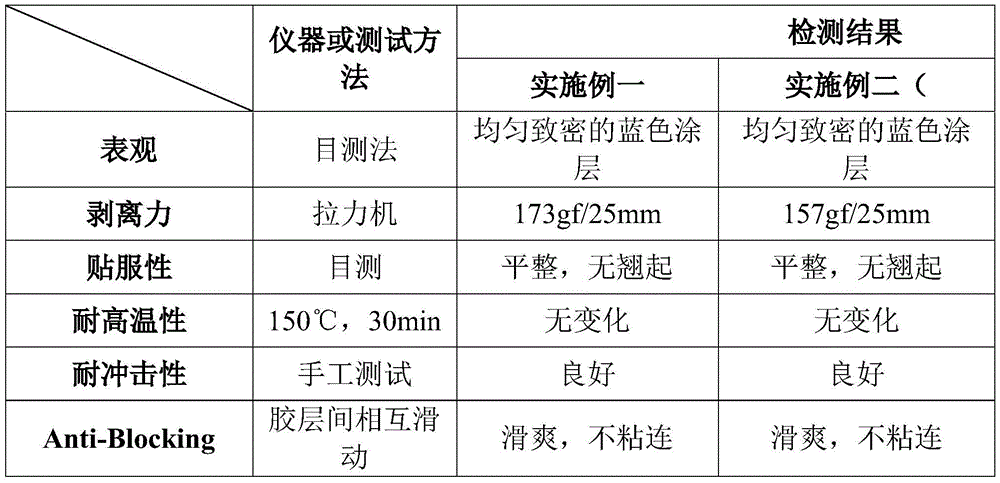

Examples

Embodiment 1

[0029] (S1) Preparation of peelable adhesive coating composition: 112g of aliphatic urethane acrylate W4048 (manufactured by Guangzhou Wuxing Materials Co., Ltd.), 8g of tris (2-hydroxyethyl) isocyanuric acid triacrylate THEICTA were put into a 500ml shading bucket (manufactured by Double Bond Chemical Co., Ltd.) and 40g ethyl acetate, stirred evenly with a high-speed disperser. Then add 1.1g leveling agent 9137 (manufactured by Double Bond Chemical Co., Ltd.), 4.5g low surface tension affinity auxiliary agent acryloyl morpholine, 2.4g anti-blocking agent MEK-AB-402 ( Nano silica slurry, manufactured by Nissan Chemical Co., Ltd.) and 6g photoinitiator 184 (manufactured by Tianjin Tianjiao Chemical Co., Ltd.). After the addition, stir at a high speed of 1200rpm for 60 minutes, then let it stand for more than 60 minutes to defoam naturally, obtain a peelable adhesive coating composition and dilute the peelable adhesive viscosity to 50±5cps with 70g of ethyl acetate;

[0030] (S...

Embodiment 2

[0032] (S1) Preparation of peelable adhesive coating composition: put 100g of aliphatic urethane acrylate LED9300 (manufactured by Guangzhou Wuxing Materials Co., Ltd.), 12g of tris(2-hydroxyethyl)isocyanuric acid triacrylate THEICTA into a 500ml shading bucket (manufactured by Double Bond Chemical Co., Ltd.) and 40g ethyl acetate, stirred evenly with a high-speed disperser. Then add 1.0g leveling agent 9137 (manufactured by Double Bond Chemical Co., Ltd.), 4.8g low surface tension affinity auxiliary agent acryloyl morpholine, 2.4g anti-blocking agent MEK-AB-402 ( Nano silica slurry, manufactured by Nissan Chemical Co., Ltd.) and 5.6g photoinitiator 184 (manufactured by Tianjin Tianjiao Chemical Co., Ltd.). After the addition, stir at a high speed of 1200rpm for 60 minutes, then let it stand for more than 60 minutes to defoam naturally, obtain a peelable adhesive coating composition and dilute the peelable adhesive viscosity to 50±5cps with 66g of ethyl acetate;

[0033] (S2)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com