Plastic bag sealing strip mounting equipment

A technology for installing equipment and sealing strips, which is applied in the field of installing equipment for plastic bag sealing strips, can solve the problems of failure to report in time, time-consuming, labor-intensive costs, and low operating efficiency, and achieve time-saving, labor-saving, low cost, simplified installation procedures, and improved operating efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

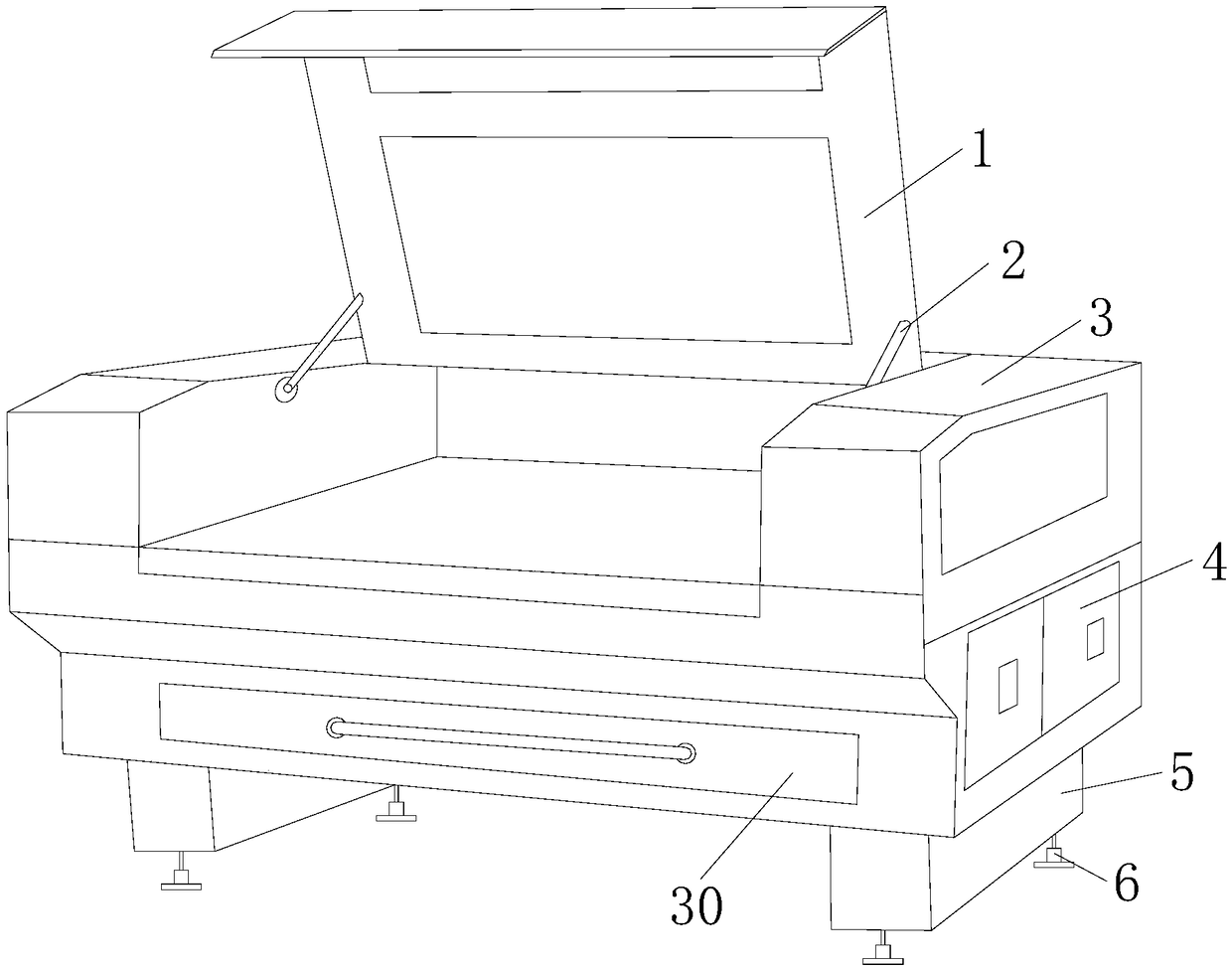

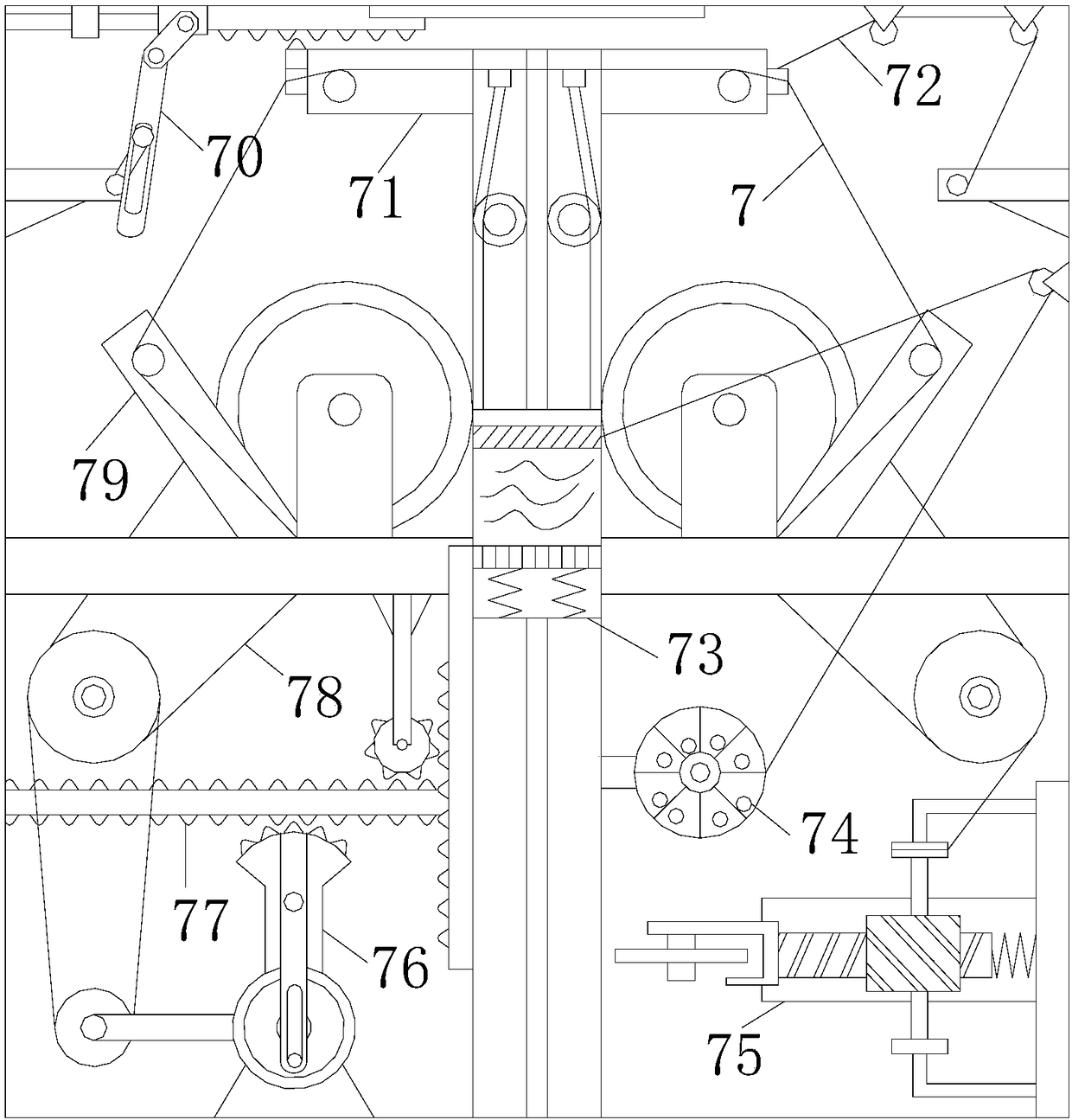

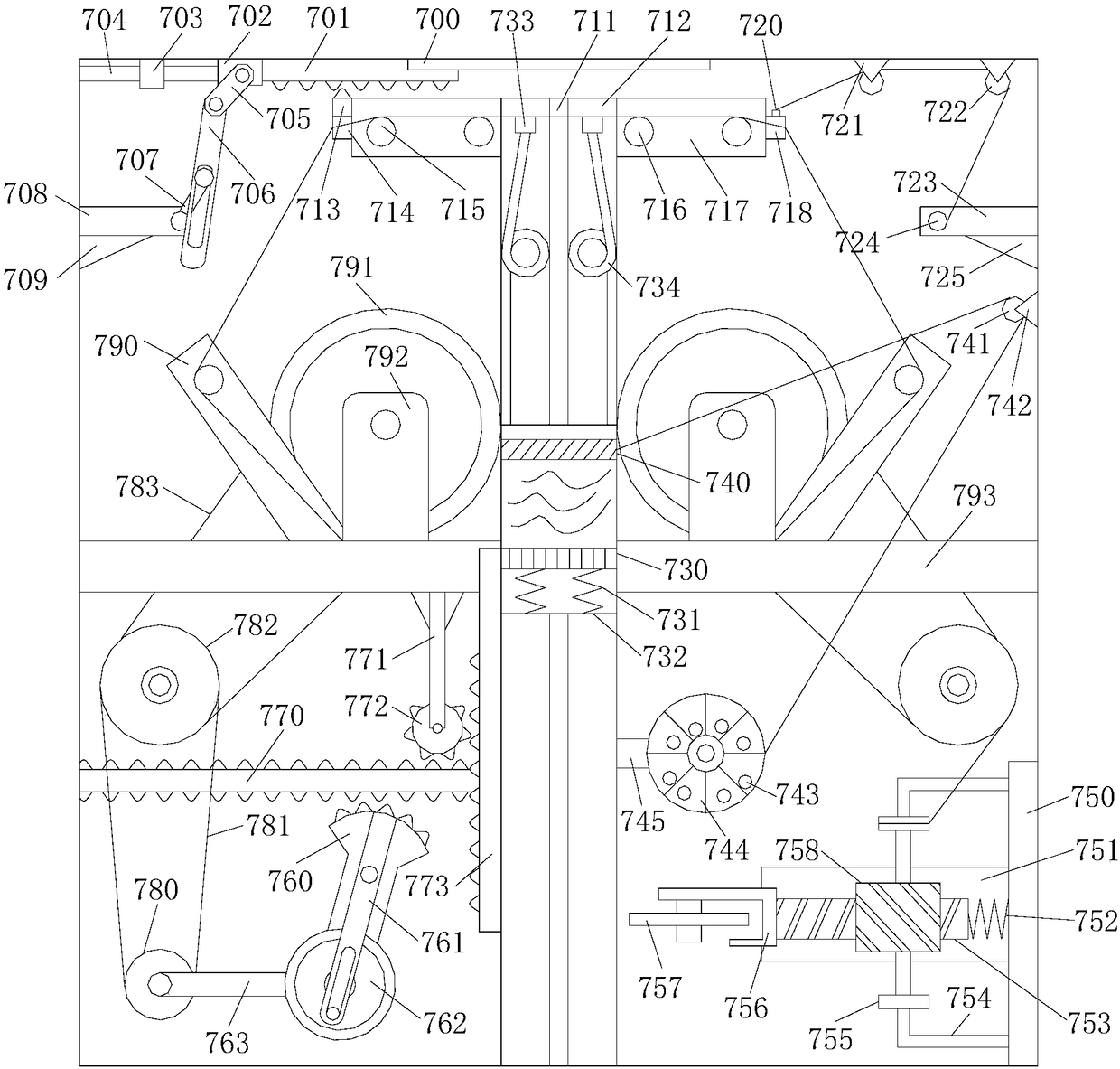

[0025] see Figure 1-Figure 3 , the present invention provides a plastic bag sealing strip installation device: its structure includes a machine cover 1, a flip telescopic rod 2, a body 3, an invisible warehouse 4, a base 5, a foot 6, and a connecting structure 7, and the machine cover 1 stretches through the flip The rod 2 is movably connected to the body 3, the cover 1 matches the body 3, the side of the body 3 is equipped with an invisible warehouse 4, the base 5 is vertically connected to the bottom of the body 3, and the base 5 and the body 3 are composed of Inverted U-shaped structure, the two form an integrated structure, the bottom of the base 5 is equipped with a leg 6, the connecting structure 7 is located inside the body 3, the front end of the body 3 is equipped with a drawer 30, and the connecting structure 7 is composed of Pushing mechanism 70, connecting mechanism 71, pulling structure 72, extruding structure 73, alarm structure 74, cutting device 75, swinging m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com