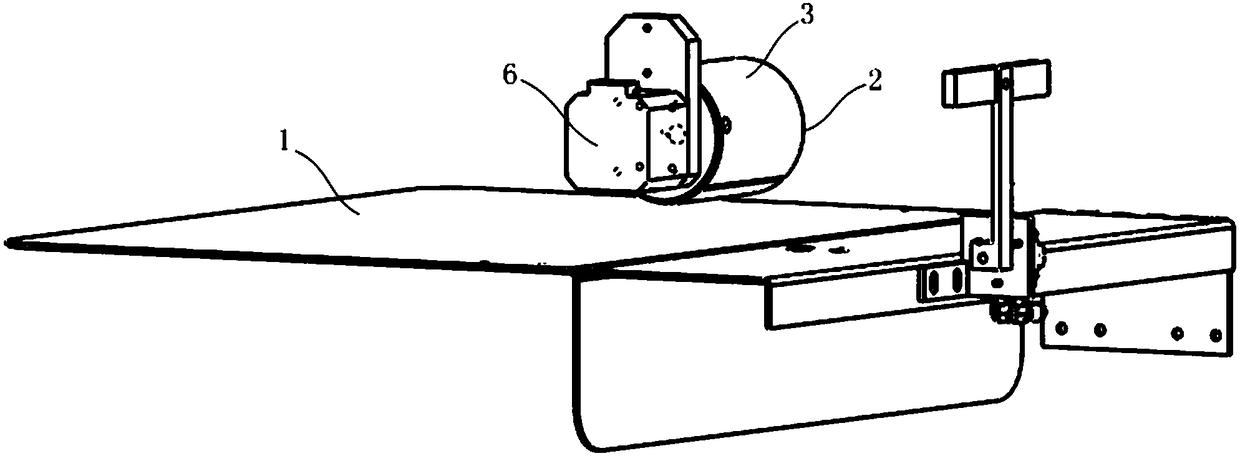

Method for improving stability of cloth separation by friction wheel, and cloth separating device

A separation device and friction wheel technology, applied in pile separation, object separation, thin material processing, etc., can solve problems such as reducing the success rate, and achieve the effects of improving stability, ensuring success rate, and increasing contact area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1 provides an embodiment of the method for improving the stability of the friction wheel separating cloth according to the present invention.

[0030] The method of improving the stability of the friction wheel to separate the cloth in the first embodiment is as follows: set a friction member made of flexible material or elastic material under the friction wheel, and place the cloth to be separated on the friction member. When the outer surface of the friction wheel is in contact with the uppermost layer of cloth in a stack of cloth to be separated, the rotation of the friction wheel drives this layer of cloth to slide forward and separate from the stack of cloth to be separated.

[0031] Since the friction parts are made of flexible materials or elastic materials, the friction parts can be deformed under the pressure of the friction wheel when the cloth is separated, so the equivalent stiffness of the part below the uppermost cloth of the cloth to be separate...

Embodiment 2

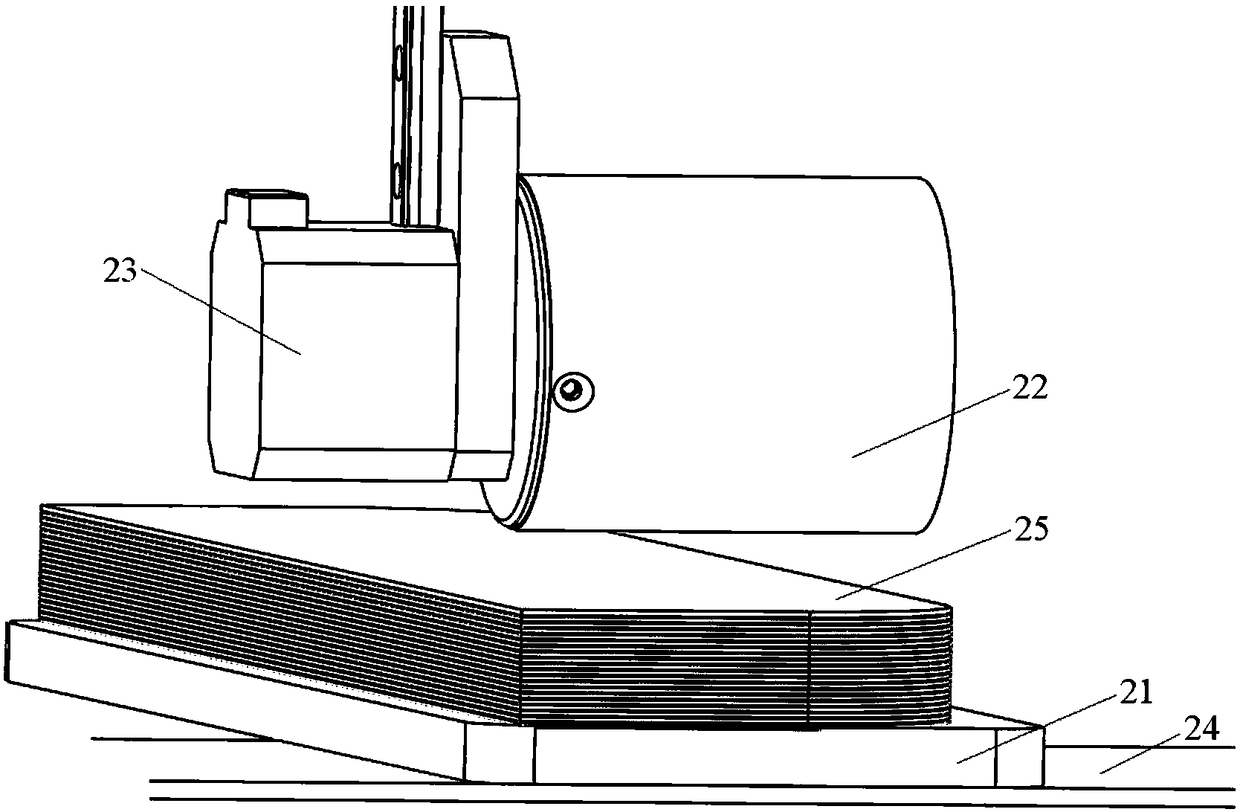

[0037] Such as figure 2 As shown, Embodiment 2 provides an embodiment of the cloth separating device of the present invention. The material separating device of the second embodiment is used to realize the method for improving the stability of the friction wheel separating the material described in the first embodiment.

[0038] The cloth separating device of the second embodiment includes: a friction component 21 , a friction wheel 22 and a driving component 23 . The friction member 21 is used to place the cloth 25 to be separated. The friction member 21 of the second embodiment is made of flexible material or elastic material, and the friction member 21 can move up and down. The friction wheel 22 is arranged above the friction member 21 , and the axis of the friction wheel 22 is parallel to the upper surface of the cloth to be separated 25 placed on the friction member 21 . The driving part 23 is connected with the friction wheel 22, and the driving part 23 drives the fri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com