Production method of nano-anion textile fabric

A nano-anion and textile fabric technology, which is applied in the processing of textile materials, continuous processing of textile materials, and processing of textile material drums, etc., can solve the problems of slow production speed and no production method, and achieve fast production, shortening time, and application wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

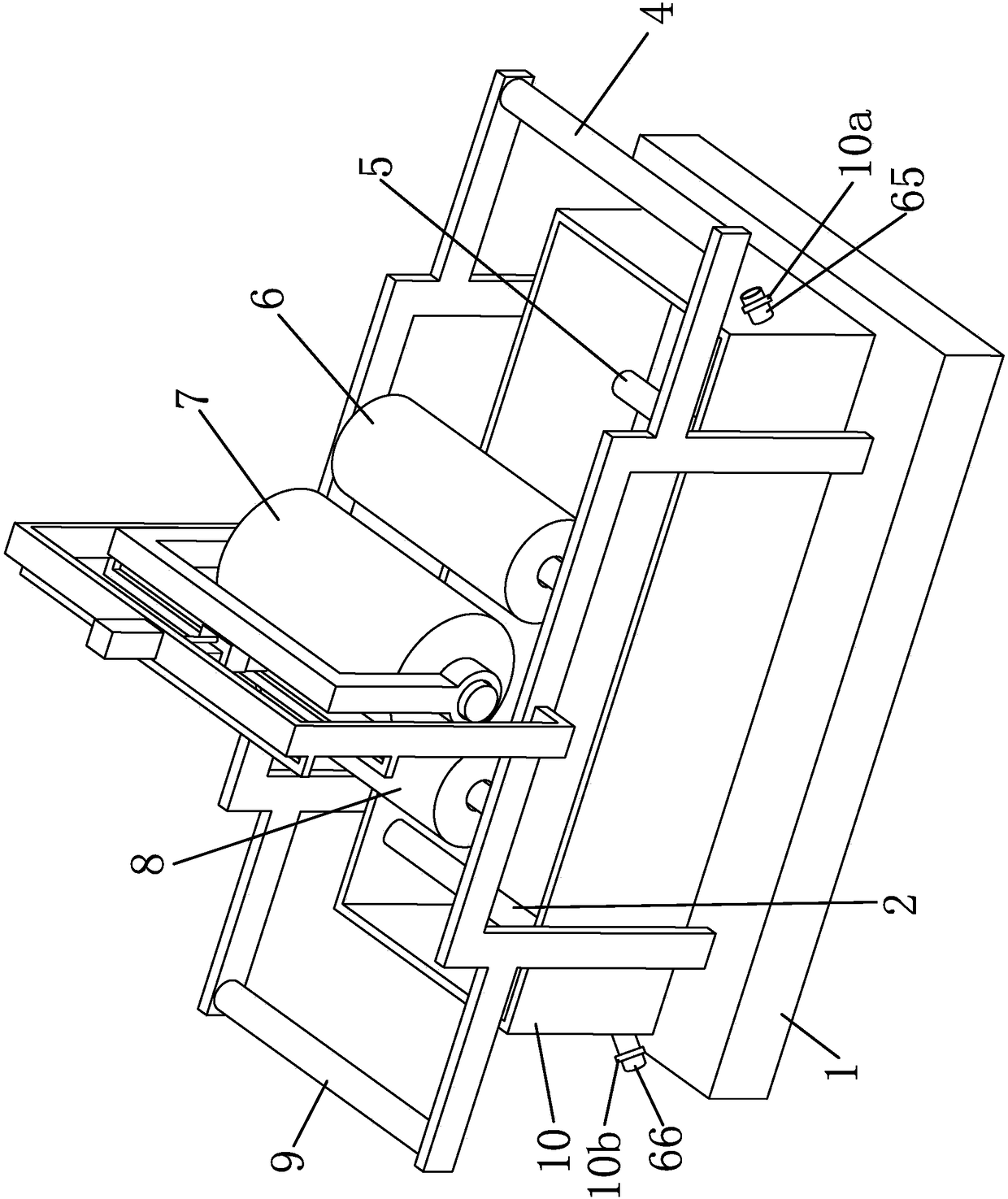

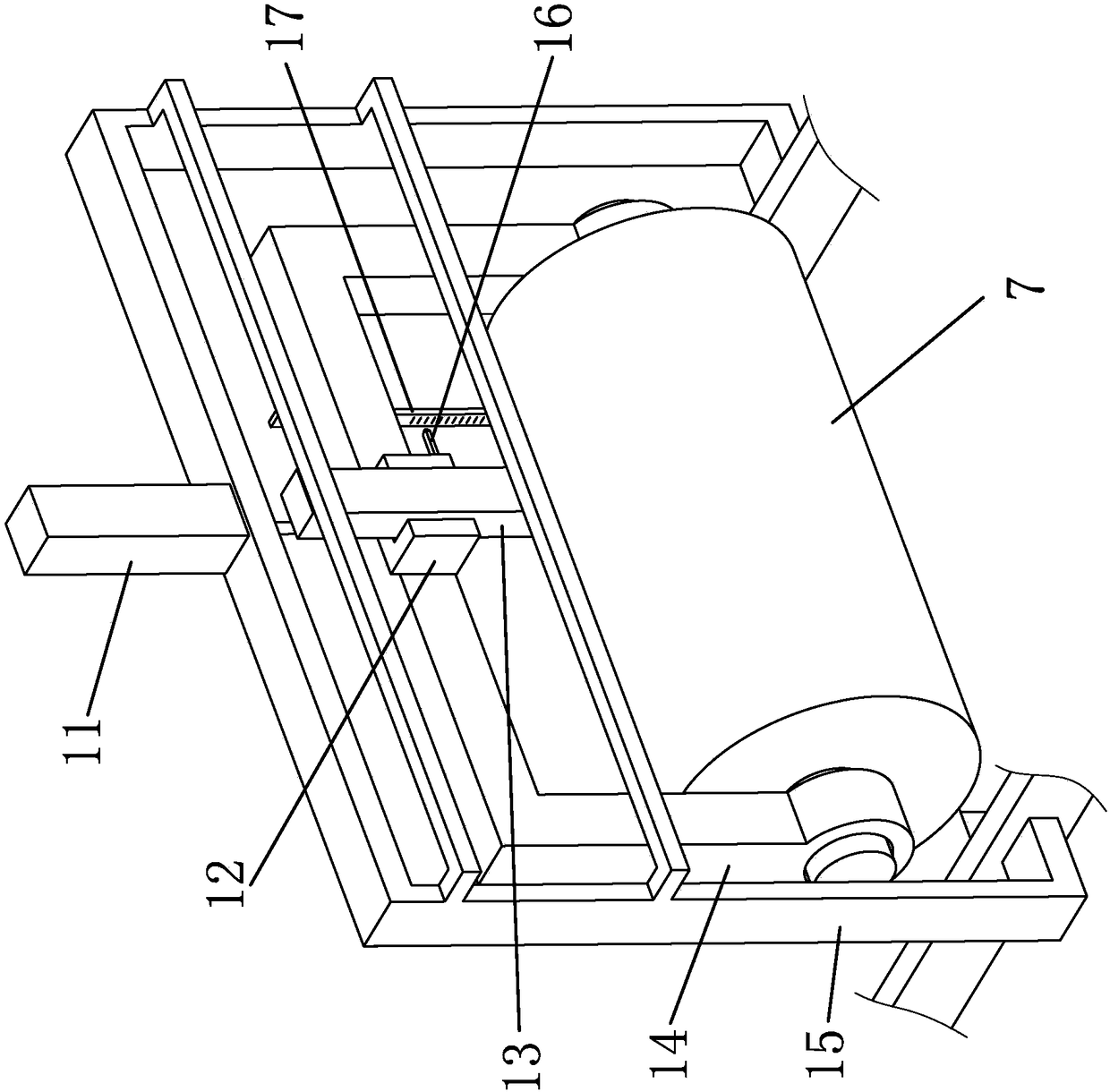

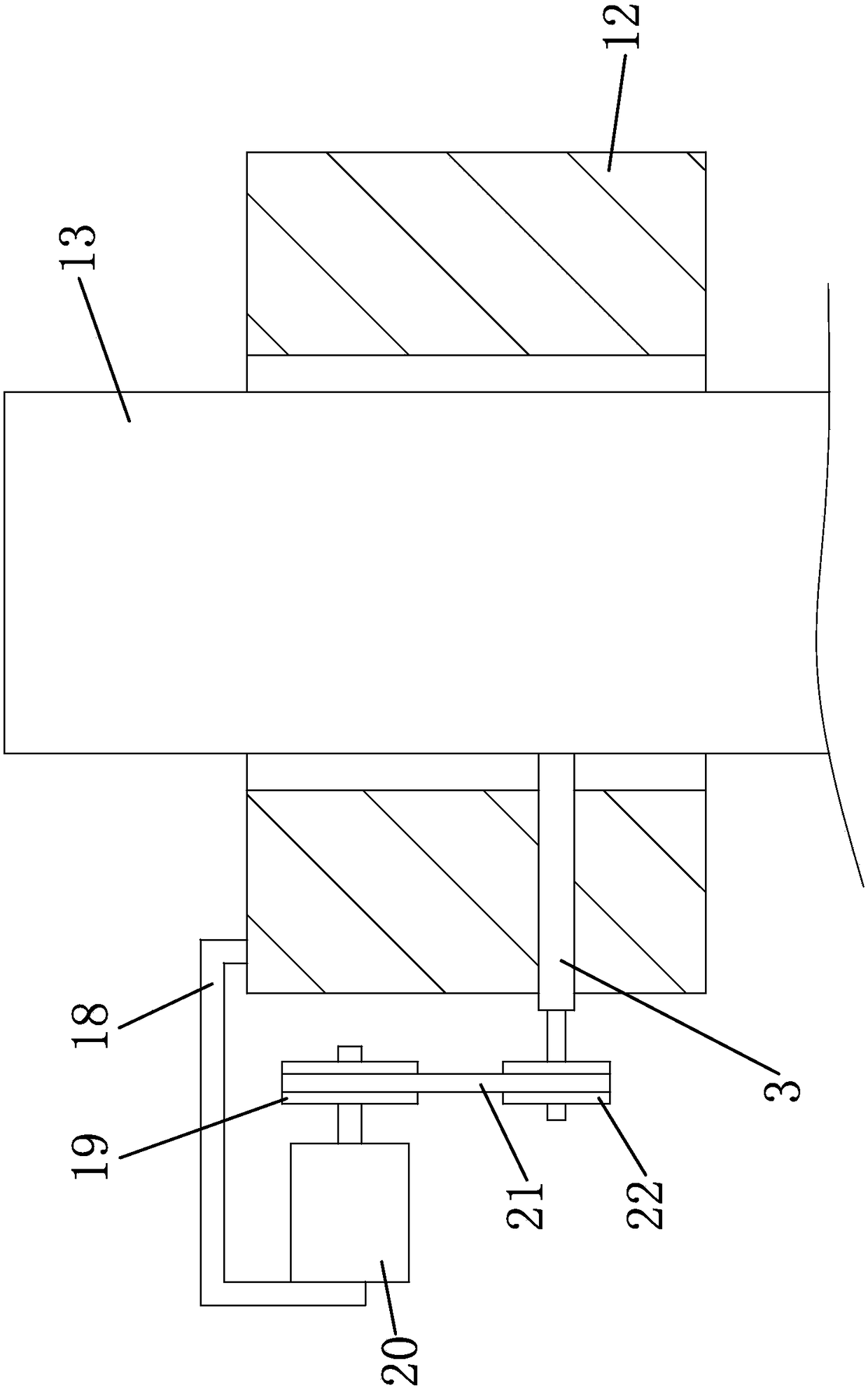

[0041] The following are specific embodiments of the present invention combined with the accompanying drawings to further describe the technical solutions of the present invention, but the present invention is not limited to these embodiments.

[0042] The production method of the nano anion textile fabric includes the following steps: a. Padding: impregnate the textile fabric with finishing solution through the padding system, the immersion time is 10-20s, and the surplus rate is 75-85%; b. Pre-baking: Pre-baking the fabric at a temperature of 140-150℃ and a time of 20-30s; c. Baking: Baking the fabric at a temperature of 158-166℃ and a time of 5-10min; d. Washing: Use the fabric for 15 After washing in cold water at -25°C for 4-8 minutes, wash with hot water at 60-70°C for 1-3 minutes; e. Drying: Dry the fabric again at a temperature of 110-120°C to prepare nano anion textile fabrics; In this embodiment, a, padding: the textile fabric is dipped in the finishing solution through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com