Intelligent fault diagnosis method for pump station main device

A fault diagnosis and main equipment technology, applied in the field of signal processing, can solve the problems of high calculation time, low diagnostic accuracy, and complicated parameter adjustment, so as to improve accuracy and effectiveness, reduce modal aliasing, and high The effect of diagnostic accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

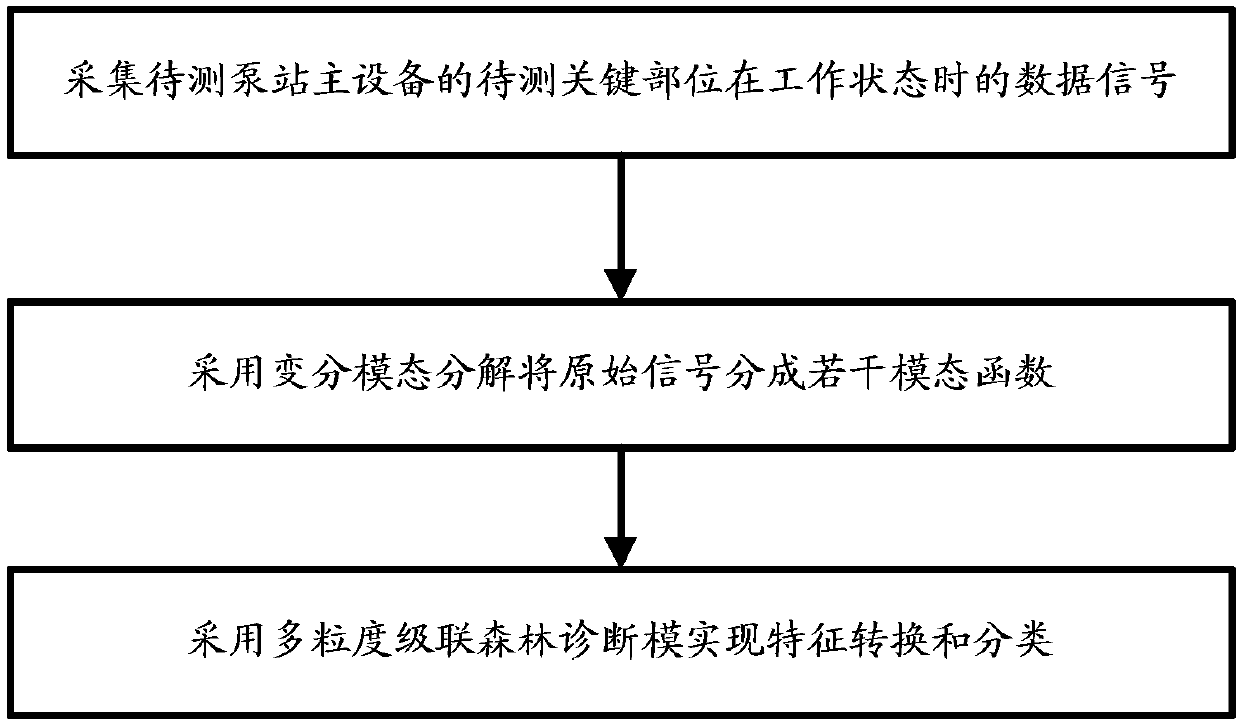

[0061] The intelligent fault diagnosis method for the main equipment of the pumping station described in this embodiment includes:

[0062] S1, collect the data signal of the key parts to be tested in the working state of the main equipment of the pump station to be tested, and use the data signal as the sample to be tested;

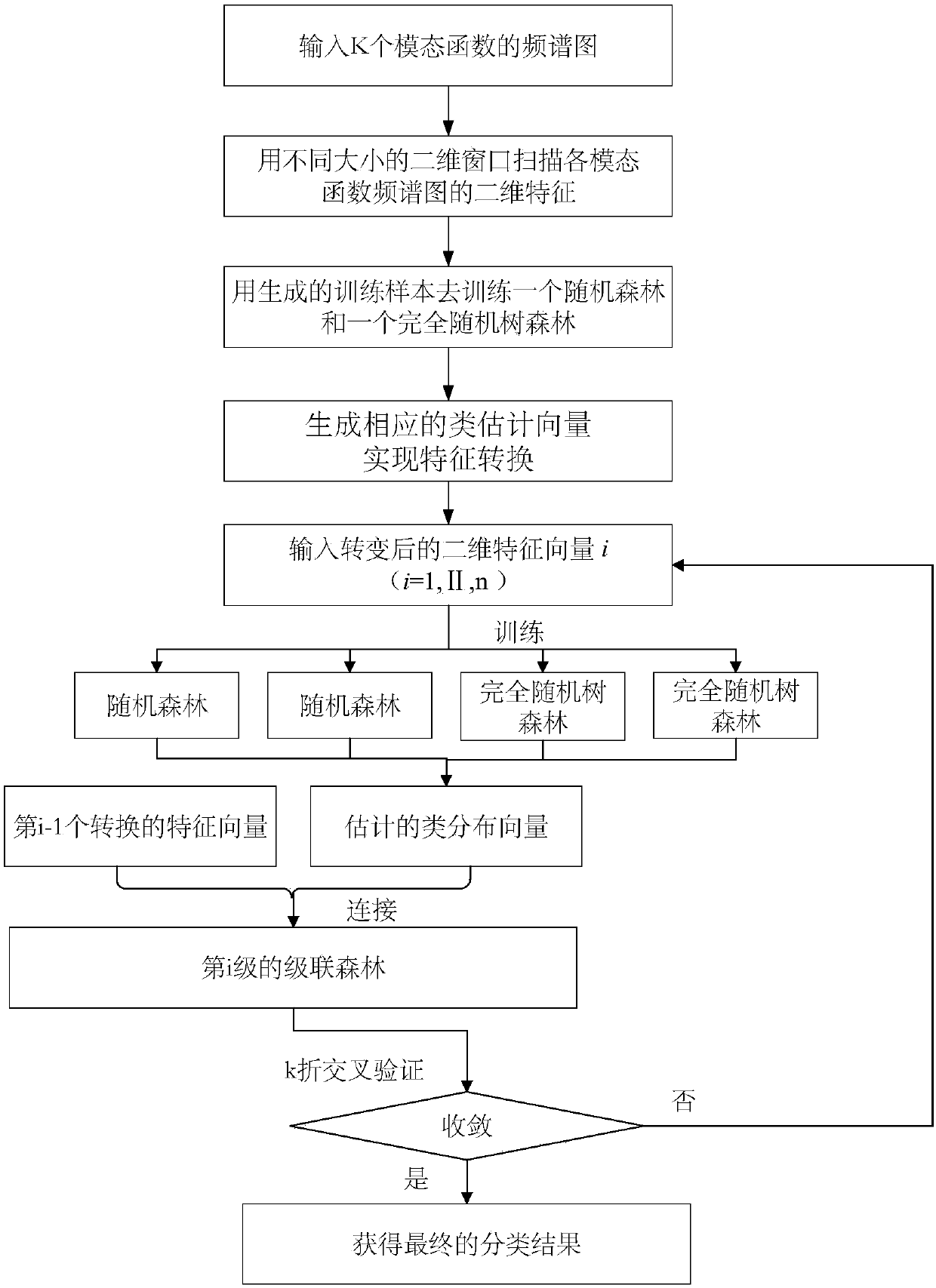

[0063] S2, input the sample to be tested into the VMD-gcForest diagnostic model, and sequentially perform the drawing of the modal function spectrogram and the multi-granularity cascade forest diagnosis to obtain the working status label corresponding to the sample to be tested, and according to the work The status label obtains the working status of the key parts to be tested;

[0064] The VMD-gcForest diagnostic model includes a variational mode decomposition module and a multi-granularity cascaded forest diagnostic model;

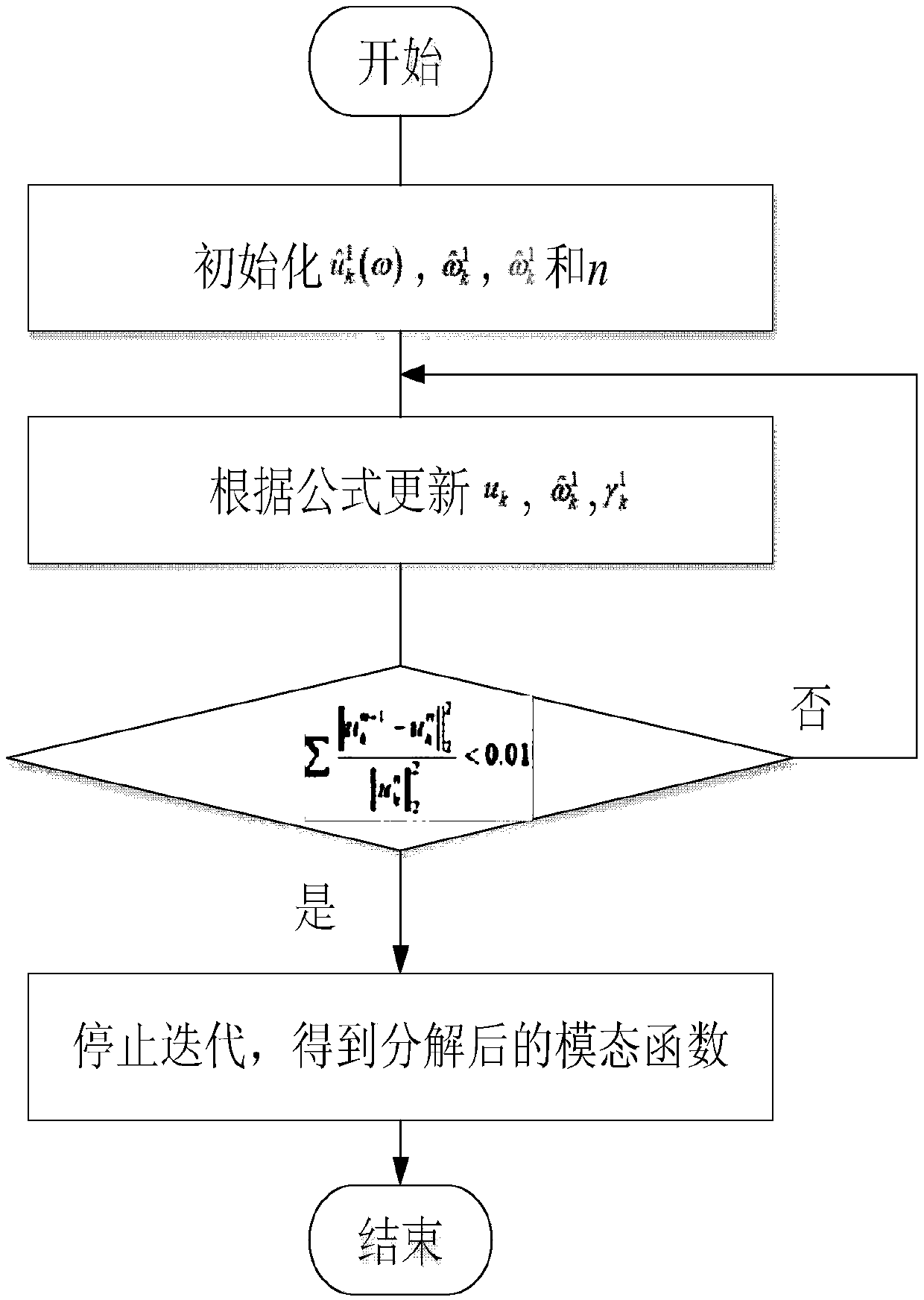

[0065] The variational mode decomposition method is integrated in the variational mode decomposition module;

[0066] The const...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com