Motor coil winding device based on crank slider mechanism principle

A technology of a crank slider mechanism and a winding device, which is applied in the direction of electromechanical devices, manufacturing motor generators, electrical components, etc., can solve the problems of poor product quality, low winding efficiency, and high labor intensity, so as to improve winding efficiency, The effect of improving product quality and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

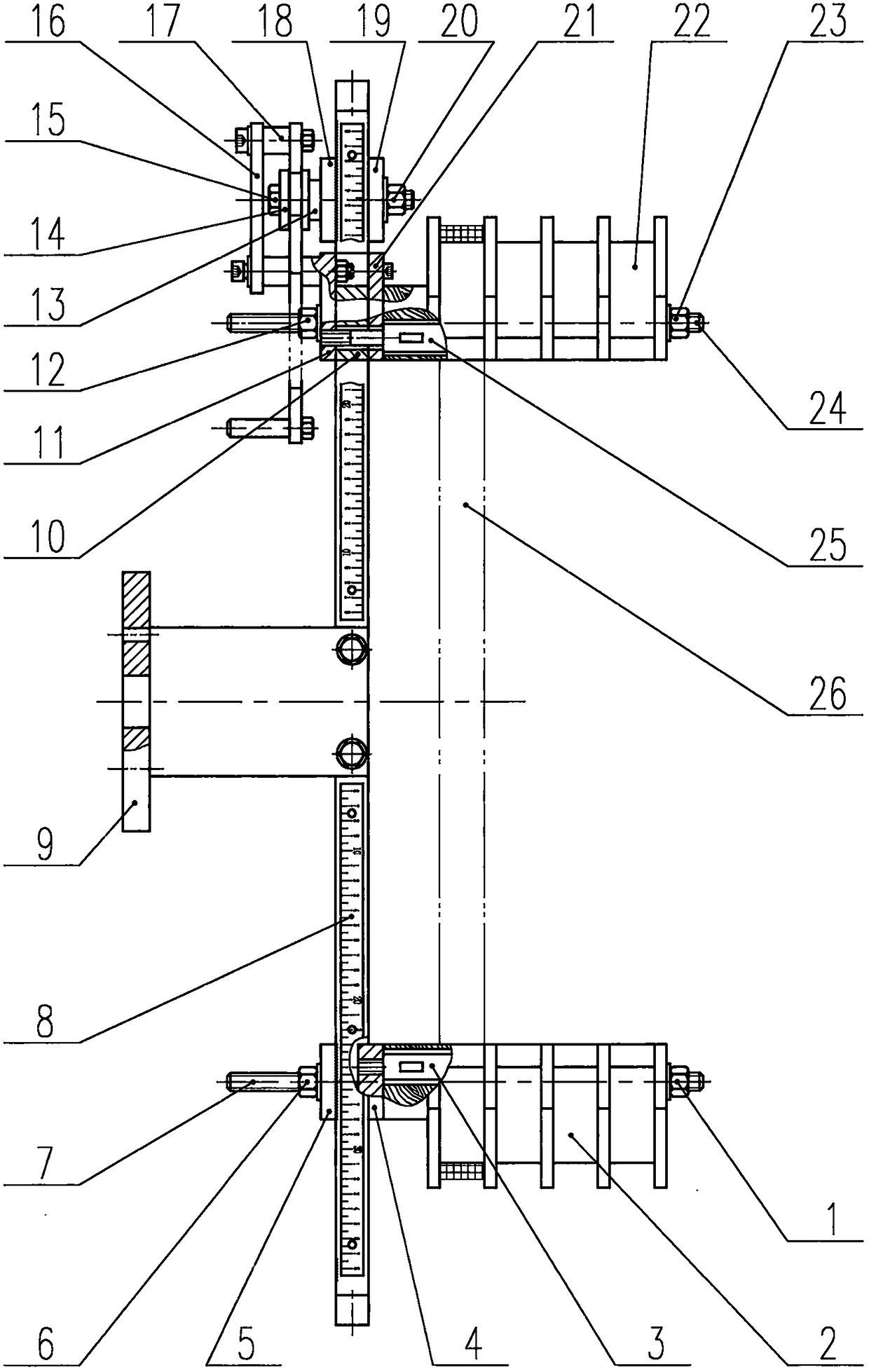

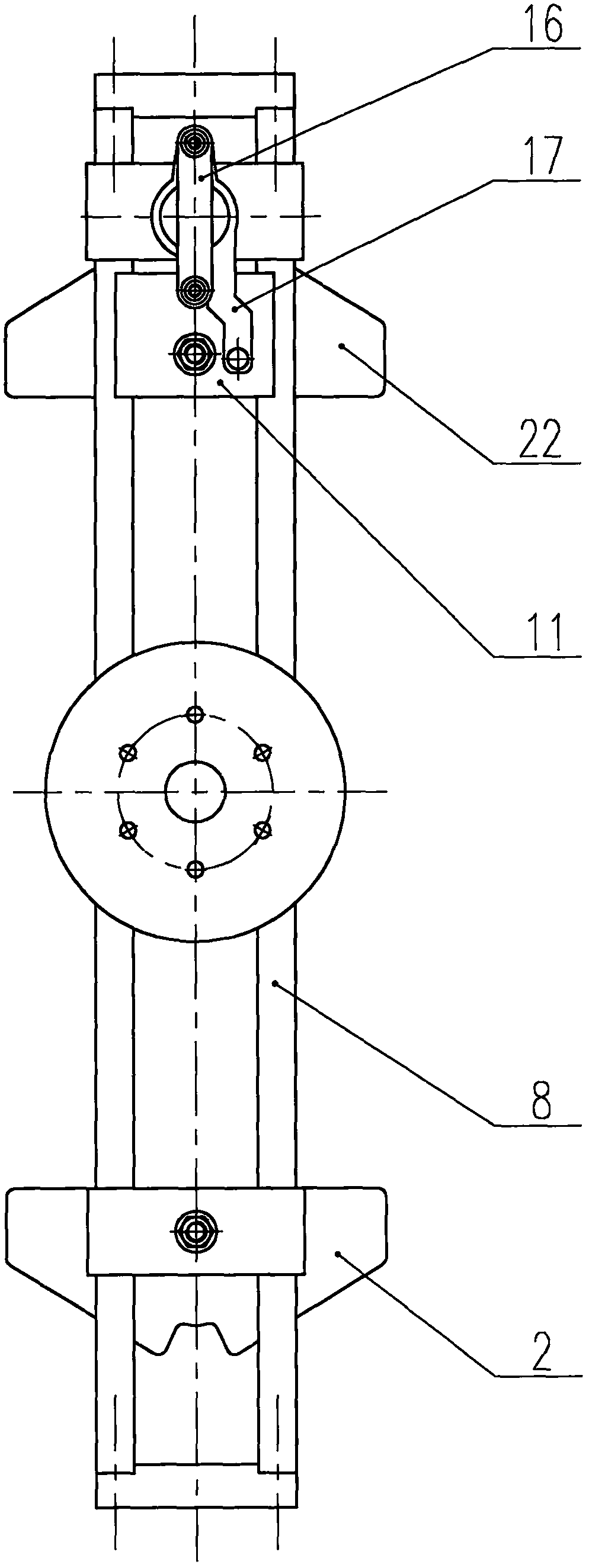

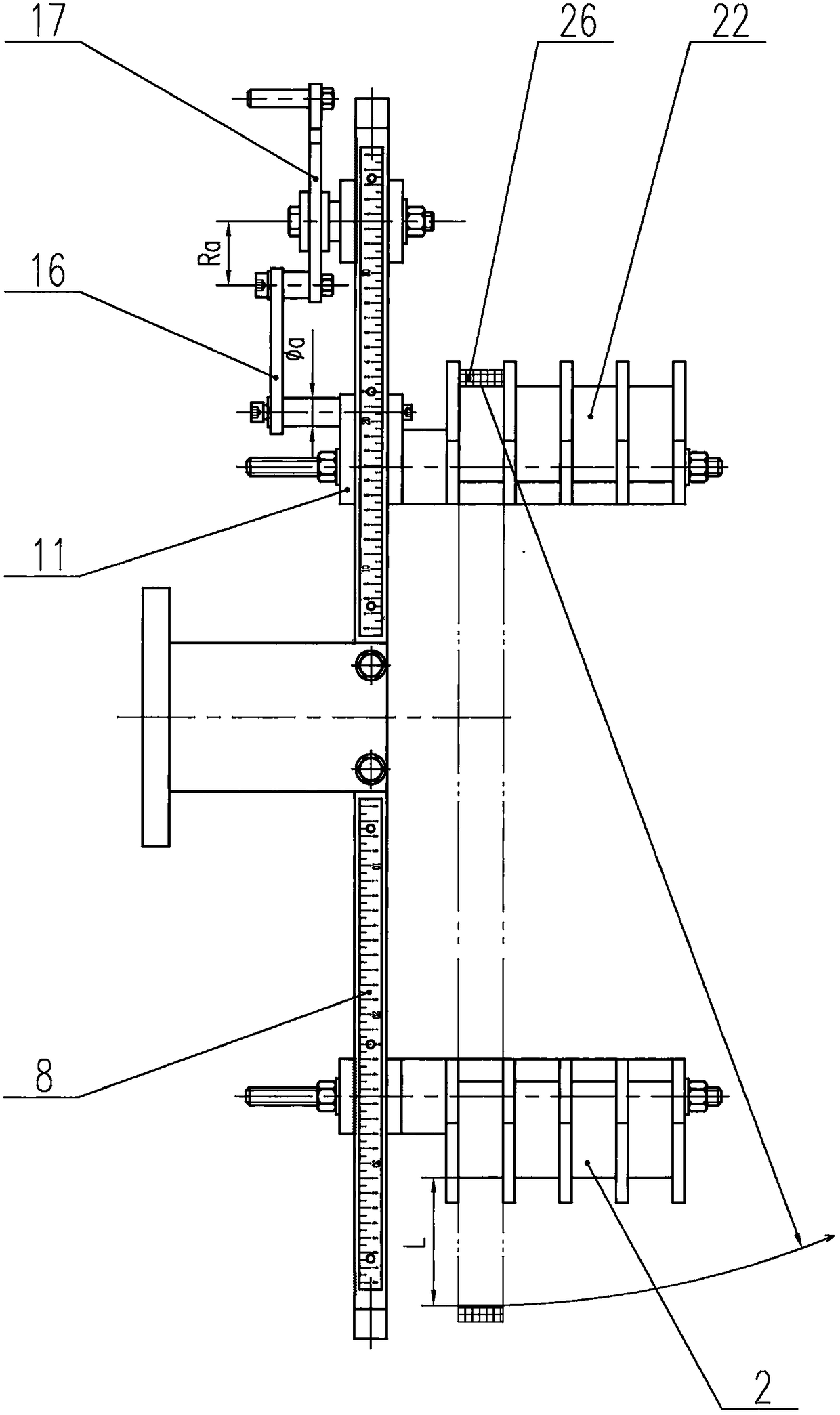

[0037] The present invention will be described in further detail below. see Figure 1 to Figure 27, a motor coil winding device based on the principle of a crank slider mechanism consists of a lower winding die 2, a winding frame 8, a lower winding die fixing mechanism, a winding frame seat 9, a slider mechanism, a connecting rod 16, and a crank plate 17, the crank disc supporting mechanism and the upper winding die 22 are formed. The lower winding die fixing mechanism, the crank disk support mechanism and the winding frame 8 are connected by threads to form a fixed part of the crank slider mechanism——frame. Crank plate 17, connecting rod 16, slider mechanism are crank, connecting rod and slide block of crank slider mechanism respectively. The upper winding die 22 and the lower winding die 2 are respectively assembled on the slider mechanism and the lower winding die fixing mechanism. The fast switching between the winding state and the unloading state of the winding device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com